Centrifugal front-mounted degassing pump and degassing technological process experimental equipment

A front-mounted, centrifugal pump technology, used in mechanical equipment, non-variable-capacity pumps, pumps, etc., can solve the problems of reduced separation efficiency, small use range, unsatisfactory degassing effect, etc., to improve degassing efficiency, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the purpose, structure and function of the present invention, a centrifugal pre-type degassing pump and degassing process experimental equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

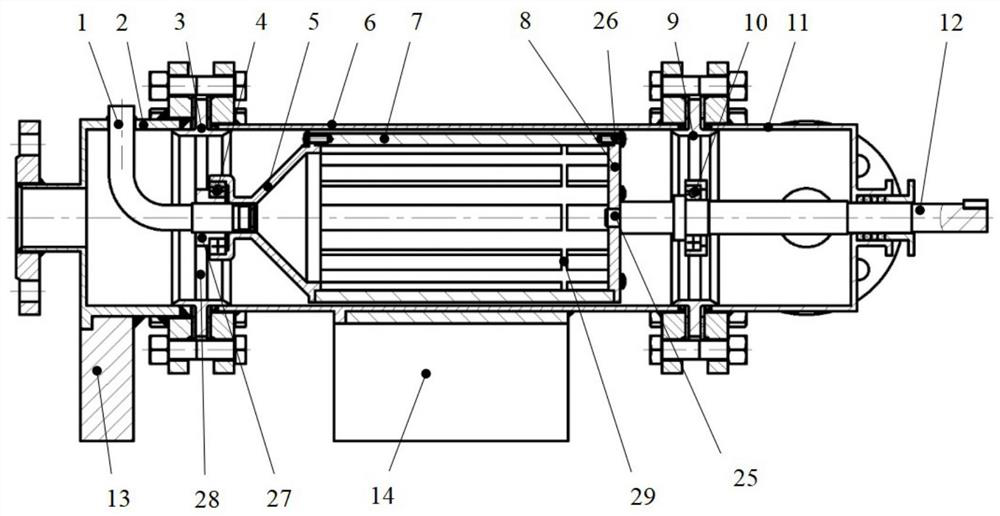

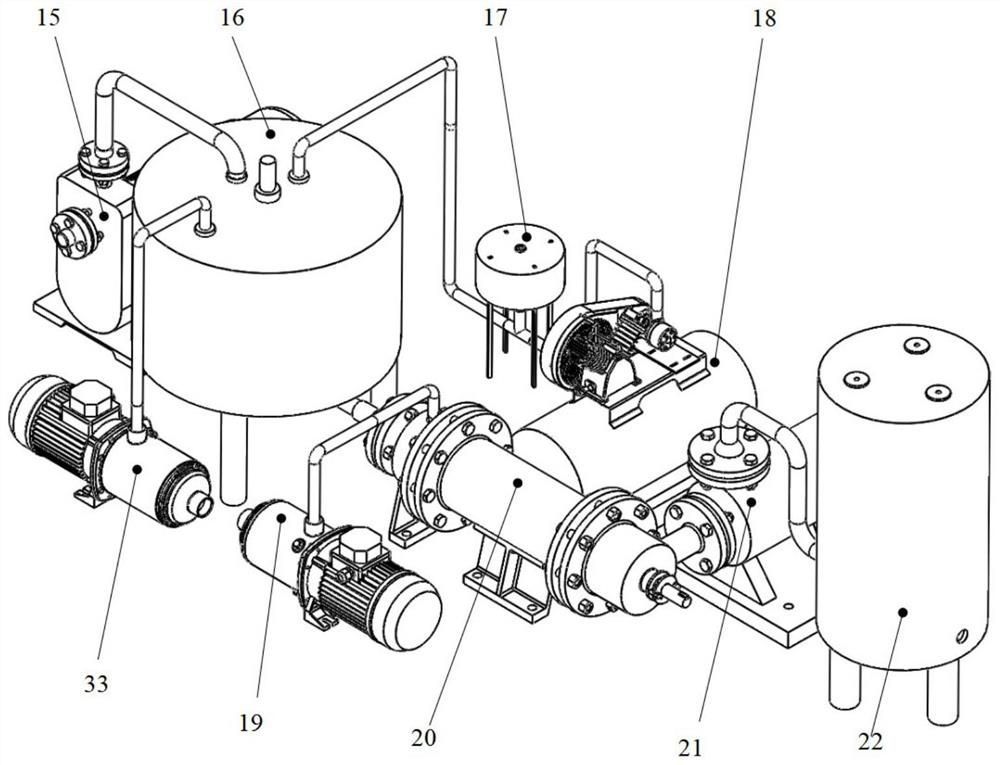

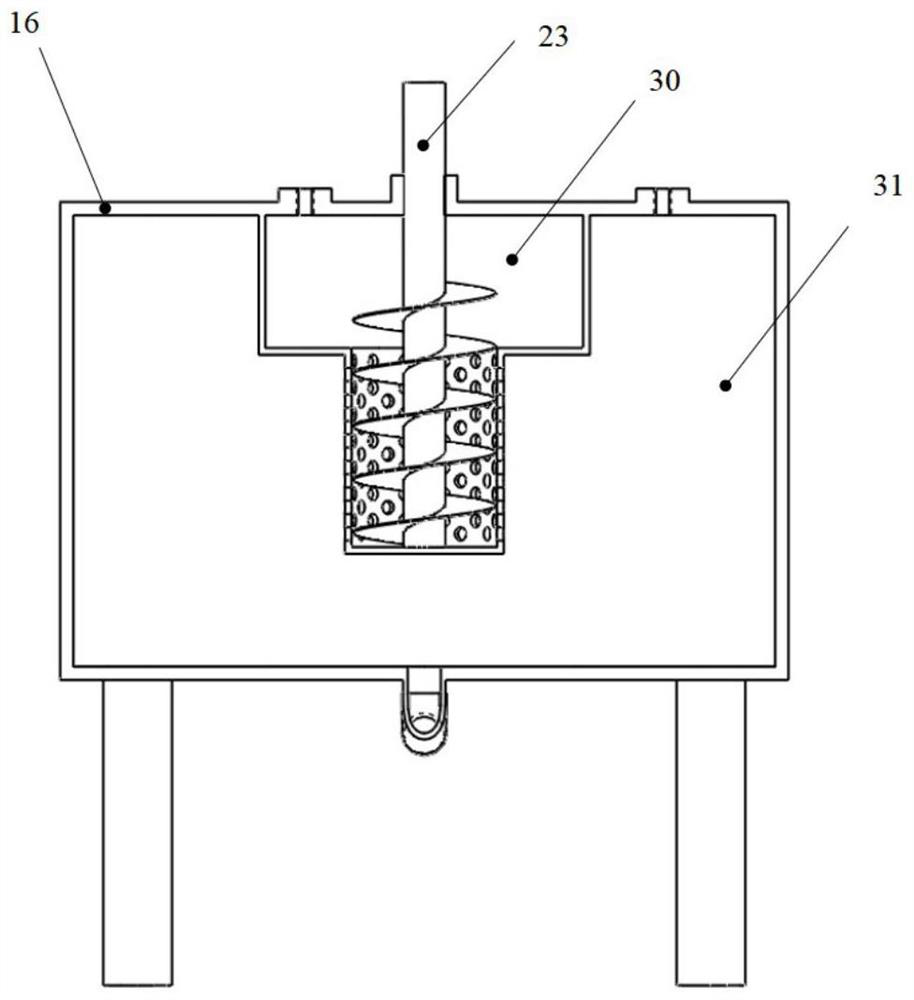

[0032] Such as Figure 1-Figure 8 As shown, the centrifugal front degassing pump of the present invention comprises: a suction head 2, an air extraction pipe 1 installed on the suction head 2, a front bearing bracket 3 successively installed under the suction head 2, a housing 6, and a rear bearing bracket 9. Water pump connector 11; wherein, the front end of the suction head 2 is provided with an opening, and the opening is a fluid inlet, and a hole of the same size as the suction pipe 1 is opened on the top for assembling the suction pipe 1, and the suction pipe 1 is connected to the first A vacuum pump 19; a hub head 5, a hub 7, a hub tail 8 and a tail end shaft 12 are installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com