Oil-gas separator with spiral line type inlet runner

A technology of oil and gas separator and inlet flow channel, which is applied in the direction of machine/engine, crankcase ventilation, mechanical equipment, etc. The effect of guaranteeing working performance and working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

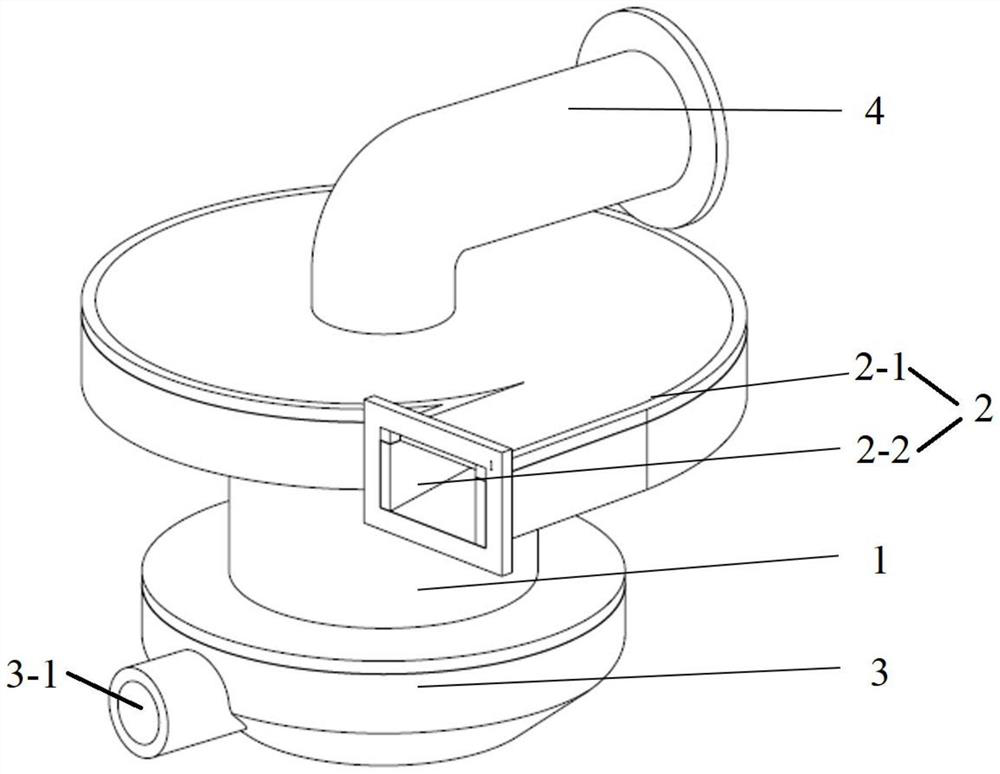

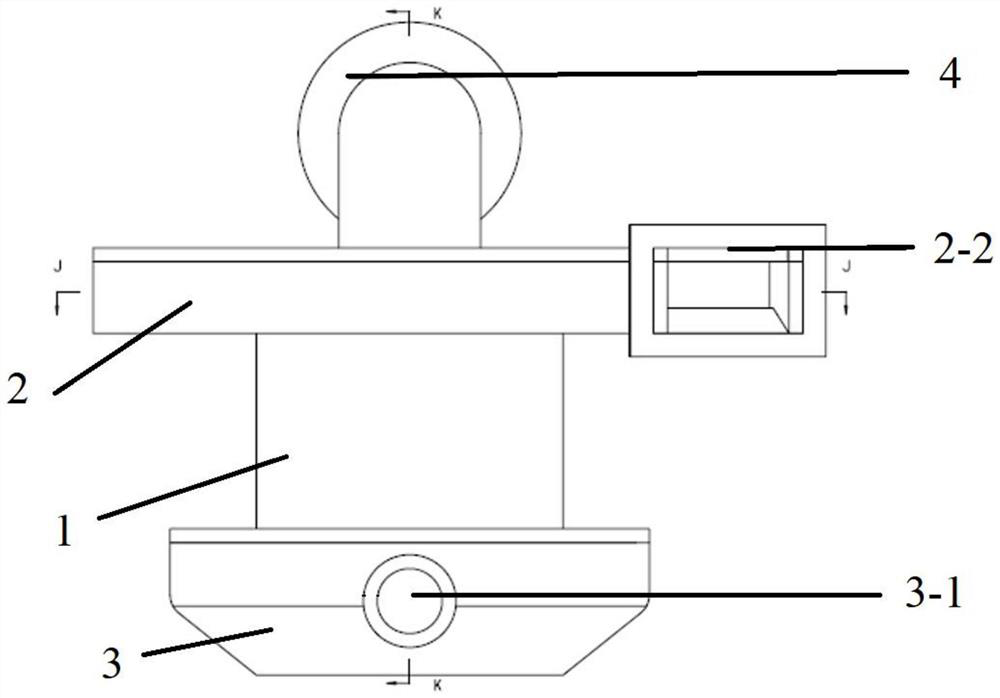

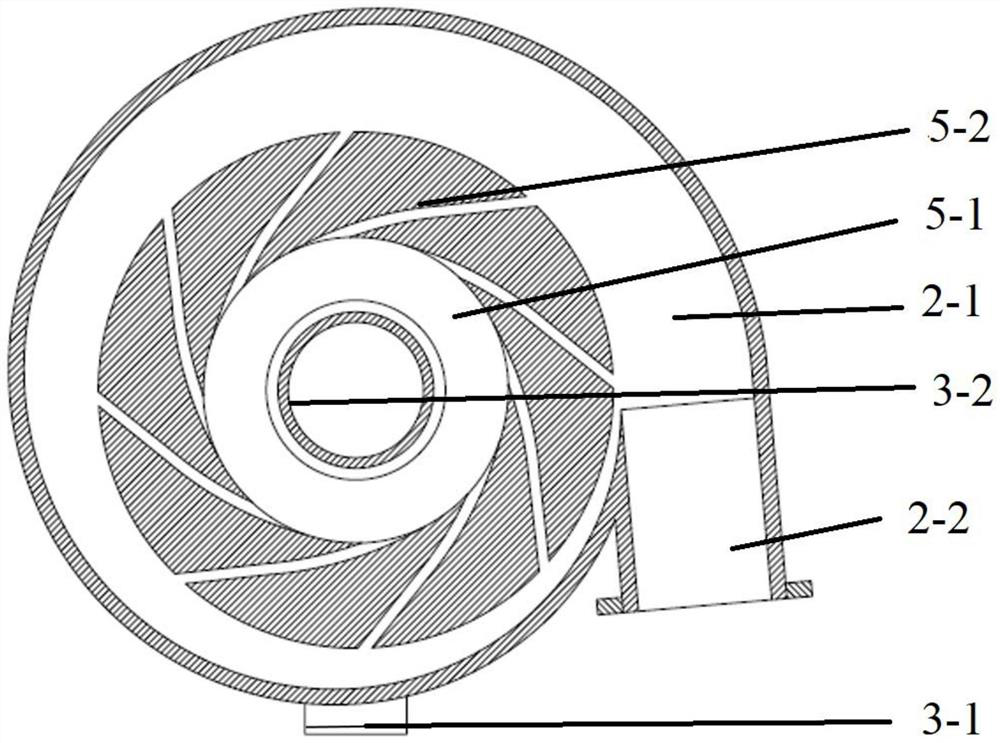

[0044] Comply with the above technical solutions, such as Figure 1 to Figure 8 As shown, an oil-gas separator with a helical inlet channel includes a separation chamber body 1, an oil-gas mixture inlet section 2 and an oil storage chamber 3 connected to both ends of the separation chamber body 1, and an oil-gas mixture inlet section 2 An exhaust pipe 4 is also connected, the exhaust pipe 4 communicates with the separation chamber cylinder body 1, the oil-gas mixture inlet section 3 communicates with the separation chamber cylinder body 1 and the oil storage chamber 3,

[0045] The oil-gas mixture inlet section 2 includes a pre-swirling flow channel 2-1 and an inlet flow channel 2-2 connected with the pre-swirling flow channel 2-1. The pre-swirling flow channel 2-1 is generally cylindrical in shape, along the An inlet flow channel 2-2 is provided in the tangential direction, and the outer wall of the pre-swirling flow channel 2-1 is an Archimedes spiral; Eight branches, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com