Damping coating for preventing termites

A damping coating and anti-termite technology, which is applied in the field of damping coatings, can solve the problems of shortening the service life of home improvement projects, corroding plastic steel bars, and reducing drug efficacy, etc., to achieve the effects of improving termite-proof function, improving damping performance, and enhancing sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the described insecticide-containing micropod suspension may further comprise the steps:

[0036] Mix the protective colloid, emulsifier, water and lye to obtain a mixed aqueous phase;

[0037] Fly ash, permethrin, phoxim and terephthaloyl chloride are mixed with an organic solvent to obtain a mixed organic phase;

[0038] The mixed organic phase and the mixed water phase are emulsified, and then an aqueous solution of ethylenediamine is added to carry out interfacial polymerization reaction to obtain a microcapsule suspension containing insecticide.

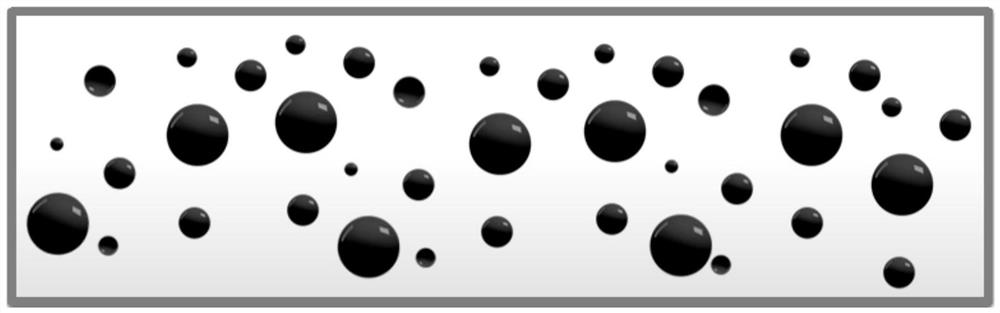

[0039] In the above preparation process, the fly ash is used as the carrier of the microcapsules, which has a porous structure and can be loaded with insecticides to achieve a slow-release effect; at the same time, it can enhance the sound-absorbing effect of the damping coating and increase the loss coefficient; the microcapsules have The structure includes a capsule core and a capsule wall, an...

Embodiment

[0048] The preparation process of anti-termite damping coating is divided into two parts:

[0049] 1) The first part is to prepare microcapsule suspensions containing insecticides: it includes the following components: permethrin and phoxim insecticides are used as capsule cores, and terephthaloyl chloride and ethylenediamine are suspensions of capsule walls , the mass ratio of core wall is 1:4, sodium hydroxide is used as acid binding agent, emulsifier op-10, polyvinyl alcohol is used as protective colloid; the preparation process is as follows:

[0050] Water phase preparation: add a certain amount of polyvinyl alcohol and OP-10 in distilled water, stir evenly, add a certain amount of sodium hydroxide solution, and the stirring speed is 1000-1200 rpm;

[0051] Organic phase preparation: Dissolve fly ash powder, permethrin, phoxim and terephthaloyl chloride in organic solvent carbon tetrachloride, mix and stir evenly, and the stirring speed is 500-1000 rpm;

[0052] Emulsifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com