Fly ash cementing material

A technology of cementitious materials and fly ash, which is applied in the field of building materials, can solve the problems of limited excitation, unexplained strength, and low strength, and achieve high social and economic benefits, reduce production costs, and improve mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

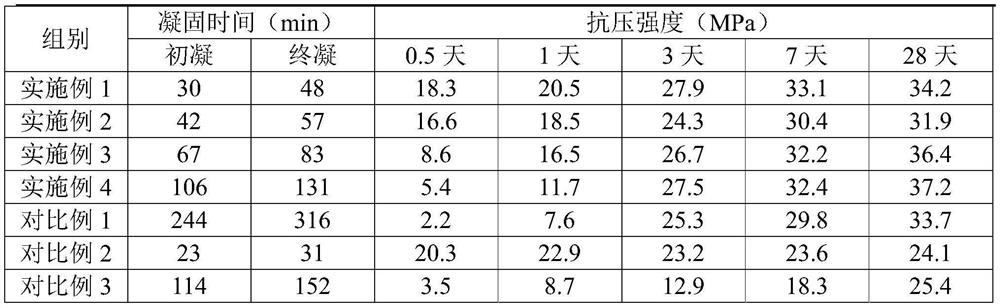

Examples

Embodiment 1

[0022] A fly ash cementitious material, comprising the following raw materials in mass fractions: 50 parts of pulverized coal furnace fly ash, 35 parts of ironmaking blast furnace slag, 5 parts of dihydrate desulfurized gypsum, 10 parts of electric furnace steel slag, 5 parts of chemical activator, 0.1 part of lignosulfonate water reducer, 0.1 part of defoamer. The mass ratio of the chemical activator is as follows: 80% of aluminum sulfate, 5% of calcium aluminate, and 15% of sodium hydroxide.

[0023] The preparation method of the fly ash cementitious material comprises the following steps: (1) each solid waste and a chemical activator are respectively ball-milled to a specific surface area ≥ 400m 2 / kg, weighed in proportion and mixed for 30 minutes until uniform, and transferred the obtained mixture to a mixer; (2) Dissolve lignosulfonate water reducer and defoamer in a certain amount of water and add them to the mixture In the process, stir at a stirring speed of 300r / min...

Embodiment 2

[0025] A fly ash cementitious material, comprising the following raw materials in mass fractions: 60 parts of pulverized coal furnace fly ash, 25 parts of ironmaking blast furnace slag, 10 parts of dihydrate desulfurized gypsum, 5 parts of electric furnace steel slag, 5 parts of chemical activator, 0.5 part of lignosulfonate water reducer, 0.1 part of defoamer. The mass ratio of the chemical activator is as follows: 90% of aluminum sulfate, 5% of calcium aluminate, and 5% of sodium hydroxide.

[0026] The preparation method of the fly ash cementitious material comprises the following steps: (1) each solid waste and a chemical activator are respectively ball-milled to a specific surface area ≥ 400m 2 / kg, weighed in proportion and mixed for 30 minutes until uniform, and transferred the obtained mixture to a mixer; (2) Dissolve lignosulfonate water reducer and defoamer in a certain amount of water and add them to the mixture In the process, stir at a stirring speed of 500r / min ...

Embodiment 3

[0028] A fly ash cementitious material, comprising the following raw materials in mass fractions: 55 parts of pulverized coal furnace fly ash, 30 parts of ironmaking blast furnace slag, 8 parts of dihydrate desulfurized gypsum, 8 parts of electric furnace steel slag, 3 parts of chemical activator, 0.1 part of lignosulfonate water reducer, 0.5 part of defoamer. The mass ratio of the chemical activator is as follows: 90% of aluminum sulfate, 1% of calcium aluminate, and 9% of sodium hydroxide.

[0029] The preparation method of the fly ash cementitious material comprises the following steps: (1) each solid waste and a chemical activator are respectively ball-milled to a specific surface area ≥ 400m 2 / kg, weighed in proportion and mixed for 30 minutes until uniform, and transferred the obtained mixture to the mixer; (2) Dissolve the water reducer and defoamer in a certain amount of water and add them to the mixture, at 300r / kg Stir at a stirring speed of min for 30 min, stir ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com