Aluminate cement and preparation method thereof

A technology of aluminate cement and red mud, which is applied in the field of cement, can solve problems such as high phosphate content, decrease in cement stone strength, and increase in cost, and achieve the effects of high specific surface area, improved hydration performance, and increased load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

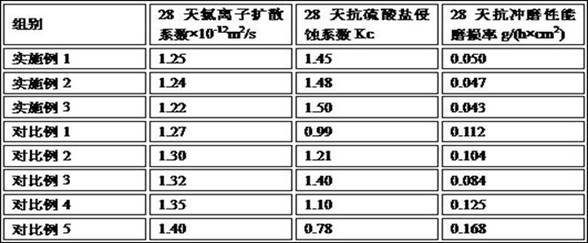

Examples

Embodiment 1

[0032] The present embodiment provides a preparation method of aluminate cement, comprising the following steps:

[0033] (1) The preparation of modified fly ash is as follows:

[0034] S1. Preparation of Porous Fly Ash: Mix 100 parts by weight of fly ash, 2 parts by weight of 400-mesh carbon powder, 5 parts by weight of binder and 2 parts by weight of calcium carbonate, add 100 parts by weight of water, stir and mix, 10h, drying, pelletizing, sintering at 1200℃ for 1h to obtain porous fly ash; the binder is a mixture of montmorillonite and starch, and the mass ratio is 3:10;

[0035] S2. the preparation of polydopamine-modified porous fly ash: adding 100 parts by weight of the porous fly ash obtained in step S1, 20 parts by weight of dopamine hydrochloride and 2 parts by weight of Tris-HCl solution with a pH value of 6 into water, Heating to 50°C, stirring for 2h, centrifuging at 3000r / min for 10min, and drying at 70°C for 2h to obtain polydopamine-modified porous fly ash; ...

Embodiment 2

[0041] The present embodiment provides a preparation method of aluminate cement, comprising the following steps:

[0042] (1) The preparation of modified fly ash is as follows:

[0043] S1. preparation of porous fly ash: mix 100 parts by weight of fly ash, 5 parts by weight of 500-mesh carbon powder, 7 parts by weight of binder and 5 parts by weight of calcium carbonate, add 100 parts by weight of water, stir and mix, 20h, drying, pelletizing by pelletizer, sintering at 1400℃ for 2h to obtain porous fly ash; the binder is a mixture of montmorillonite and starch, and the mass ratio is 5:10;

[0044] S2. the preparation of polydopamine-modified porous fly ash: adding 100 parts by weight of the porous fly ash obtained in step S1, 40 parts by weight of dopamine hydrochloride and 10 parts by weight of Tris-HCl solution with a pH value of 6.5 into water, Heating to 70°C, stirring and reacting for 4h, centrifuging at 3000r / min for 10min, and drying at 70°C for 2h to obtain polydopam...

Embodiment 3

[0050] The present embodiment provides a preparation method of aluminate cement, comprising the following steps:

[0051] (1) The preparation of modified fly ash is as follows:

[0052] S1. Preparation of Porous Fly Ash: Mix 100 parts by weight of fly ash, 4 parts by weight of 450-mesh carbon powder, 6 parts by weight of binder and 3.5 parts by weight of calcium carbonate, add 100 parts by weight of water, stir and mix, 15h, drying, pelletizing, sintering at 1300℃ for 1.5h to obtain porous fly ash; the binder is a mixture of montmorillonite and starch, and the mass ratio is 4:10;

[0053] S2. the preparation of polydopamine-modified porous fly ash: adding 100 parts by weight of the porous fly ash obtained in step S1, 30 parts by weight of dopamine hydrochloride and 5 parts by weight of Tris-HCl solution with a pH value of 6.2 into water, Heating to 60°C, stirring and reacting for 3h, centrifuging at 3000r / min for 10min, and drying at 70°C for 2h to obtain polydopamine-modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com