Concrete crushing and screening device

A screening device and concrete technology, applied in the fields of sieving, transportation and packaging, grain processing, etc., can solve the problems of reducing the clogging of aggregates and sieves, clogging of sieve holes, etc., to solve the problem of clogging of sieve holes and reduce clogging material, reducing the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

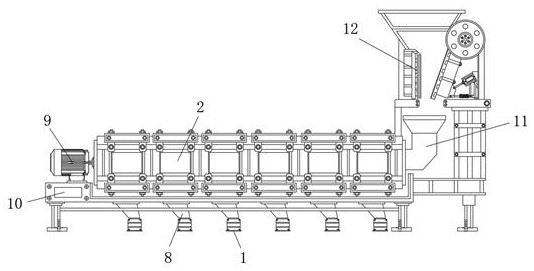

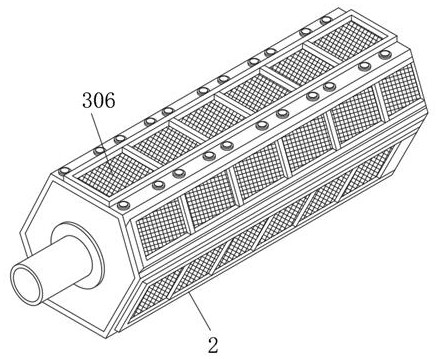

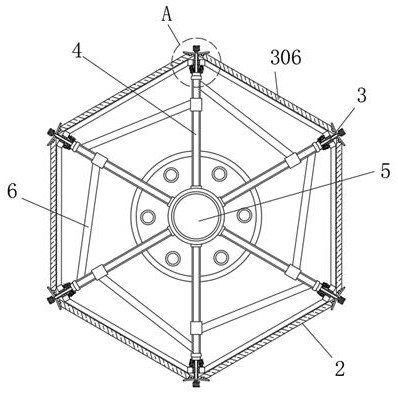

[0032] A concrete crushing and screening device, comprising: a body 1, a screening cylinder 2 and a limit mechanism 3, the outer surface of the body 1 is provided with a screening cylinder 2, the interior of the screening cylinder 2 is provided with an adjustment mechanism 4, and the adjustment mechanism 4 The bottom end is fixedly connected with a rotating mechanism 5, the inside of the adjustment mechanism 4 is provided with an upper sieve 6, the outer surface of the upper sieve 6 is equipped with a vibrating sieve mechanism 7, and the outer surface of the bottom end of the screening cylinder 2 is fixedly connected with a discharge bin 8. The left outer surface of the screening cylinder 2 is connected with a working motor 9, and the bottom end of the working motor 9 is fixedly connected with a control chip 10, and the right outer surface of the screening cylinder 2 is fixedly installed with a feed port 11, and the feed port The upper end of 11 is provided with a crushing devi...

Embodiment 2

[0035] The same features of this embodiment and Embodiment 1 will not be repeated. The difference between this embodiment and Embodiment 1 is that in this embodiment, the adjustment mechanism 4 includes a threaded seat 401, and the threaded seat 401 is fixedly connected to the outer surface of the rotating mechanism 5. On the surface, a bolt rod 402 is inserted inside the threaded seat 401, and the outer surface of the top end of the bolt rod 402 is fixedly connected with an adjustment shaft seat 403, and the outer surface of the adjustment shaft seat 403 is connected with the upper sieve sheet 6, and the adjustment shaft seat 403 and the upper sieve The sheet 6 is connected by rotation, the bolt rod 402 is rotated and connected inside the threaded seat 401, the adjusting shaft seat 403 is sleeved on the outside of the bolt rod 402, the threaded seat 401 is provided with six groups, the rotating mechanism 5 includes a rotating gear 501, and the rotating gear 501 is set Inside t...

Embodiment 3

[0037] The same features of this embodiment and Embodiment 1 will not be repeated. The difference between this embodiment and Embodiment 1 is that in this embodiment, the vibrating screen mechanism 7 includes a mounting plate 701, and the mounting plate 701 is arranged on the upper sieve plate 6. Inside, the outer surface of the mounting plate 701 is fixedly installed with a mounting base 702, the top of the mounting base 702 is fixedly connected with a second telescopic spring 704, and the inside of the second telescopic spring 704 is inserted with a limit rod 703, and the outer surface of the mounting plate 701 is fixed. A vibrating motor 705 is installed, and the tops of the vibrating motor 705 and the second telescopic spring 704 are fixedly connected to the outer surface of the sieve plate 601, and the second telescopic spring 704 is wrapped and sleeved on the outer surface of the limit rod 703, and the mounting base 702 and The vibrating motor 705 is fixedly installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com