Carbon nitride composite catalyst with porous structure as well as preparation method and application of carbon nitride composite catalyst

A composite catalyst, porous structure technology, applied in physical/chemical process catalysts, chemical instruments and methods, preparation/separation of ammonia, etc. It can solve the problems of low capacity, and achieve the effect of good photocatalytic nitrogen fixation and ammonia production, reducing the electron-hole recombination rate and accelerating the transfer of electrons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

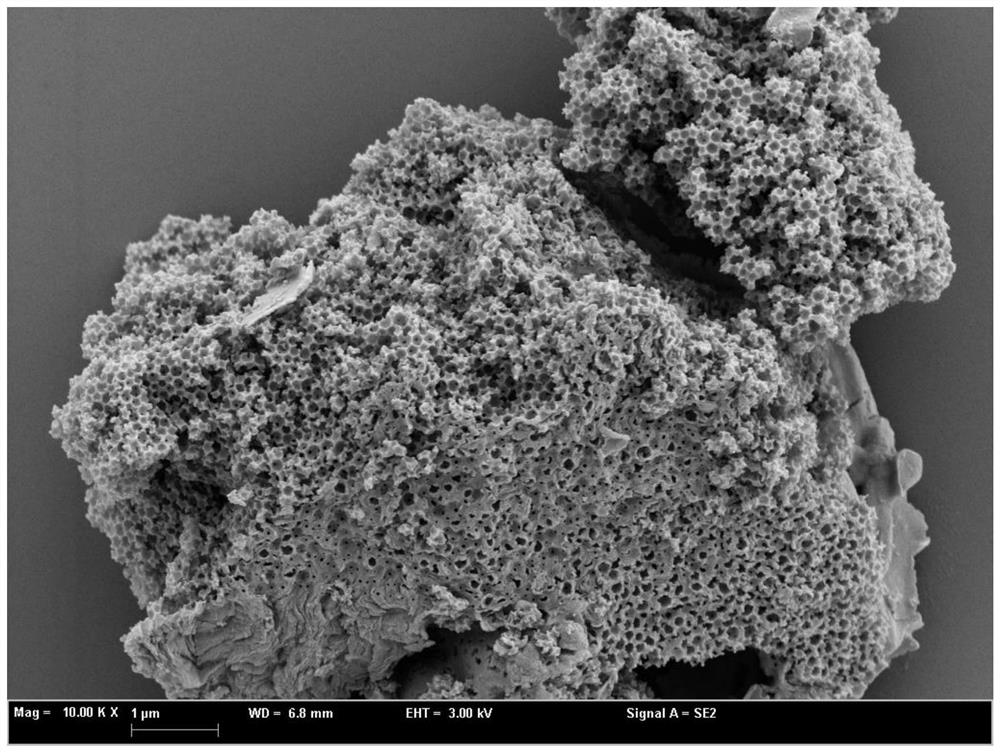

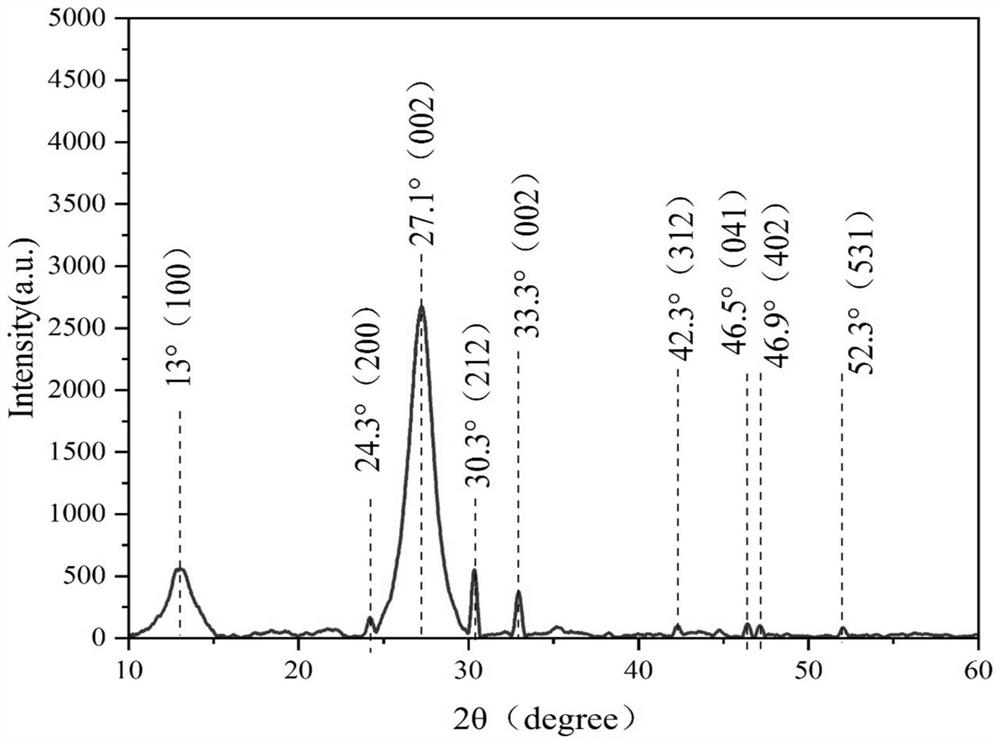

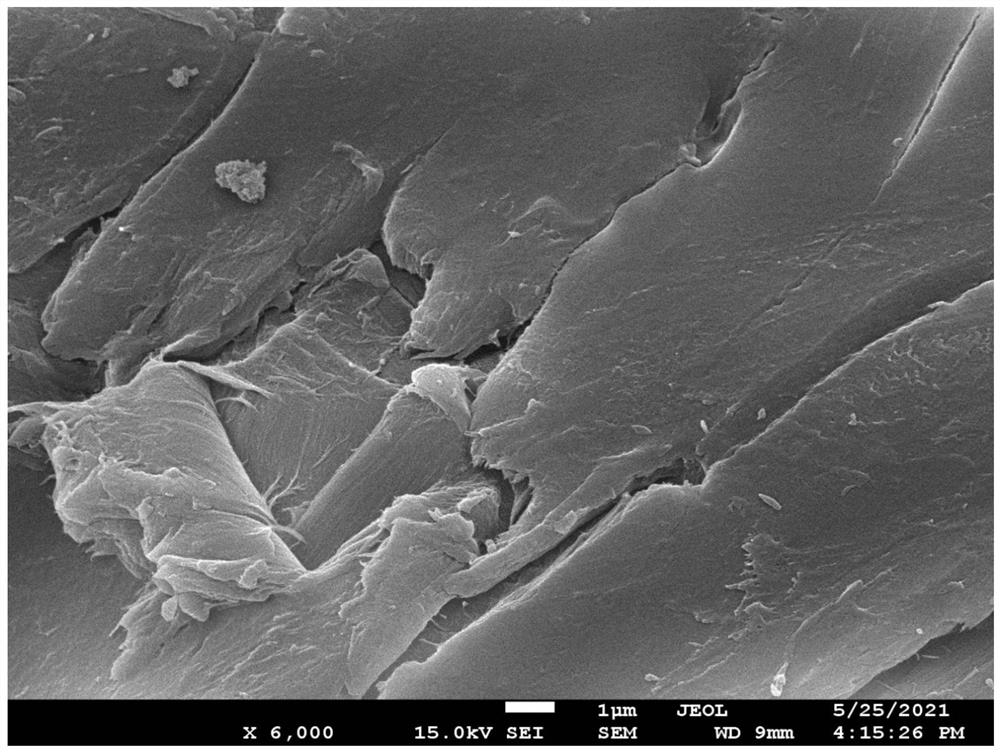

[0037] The invention provides a kind of bulk phase containing irregular porous structure carbon nitride (ipg-C 3 N 4 ) preparation method. Firstly, silica microspheres were prepared by reacting tetraethyl orthosilicate with water; dicyandiamide was used as carbon nitride precursor, the prepared silica microspheres and urea were used as templates, and hydrofluoric acid was used as etchant , prepare ipg-C by calcination and etching 3 N 4 .

[0038] Preparation of irregular porous g-C by a urea-assisted template method 3 N 4 / Bi 2 o 3 The method of composite material, concrete steps are as follows:

[0039] (A) Fully mix water, ammonia water, and ethanol at a volume ratio of 1:0.05-0.2:0.6, and record it as liquid A, preferably 1:0.08:0.6; tetraethyl orthosilicate, ethanol at a volume ratio of 1:5-20 Proportions are fully mixed and recorded as liquid B, wherein the volume ratio of water to tetraethyl orthosilicate is 1:0.1-0.5, preferably 1:0.2. After mixing liquids A a...

Embodiment 1

[0045] Preparation of irregular porous g-C by a urea-assisted template method 3 N 4 / Bi 2 o 3 The method of composite materials, the steps are as follows:

[0046] (1) Fully mix water, ammonia water (25% concentration), and ethanol at a volume ratio of 1:0.05:0.6, and record it as liquid A; fully mix tetraethyl orthosilicate and ethanol at a volume ratio of 1:20, and record It is liquid B, wherein the volume ratio of water to tetraethyl orthosilicate is 1:0.1. A and B liquids were mixed and stirred for 0.5 h, centrifuged and placed in an oven at 60°C to dry, and after grinding, white powdery monodisperse silica microspheres (MNSP-1) were obtained.

[0047] (2) Dicyandiamide, MNSP-1, and urea were dispersed in water at a mass ratio of 1:0.1:2, stirred for 60 minutes, and then dried in an oven at 60°C. After grinding, the white powder was collected for later use.

[0048] (3) Put the obtained powder into a tube furnace protected by nitrogen gas, and heat it at 5°C min -1 R...

Embodiment 2

[0052] Preparation of irregular porous g-C by a urea-assisted template method 3 N 4 / Bi 2 o 3 The method of composite materials, the steps are as follows:

[0053] (1) Fully mix water, ammonia water (28% concentration), and ethanol at a volume ratio of 1:0.07:0.6, and record it as liquid A; fully mix tetraethyl orthosilicate and ethanol at a volume ratio of 1:15, and record It is liquid B, wherein the volume ratio of water to tetraethyl orthosilicate is 1:0.3. A and B liquids were mixed and stirred for 3 hours, centrifuged and placed in an oven at 60°C to dry. After grinding, white powdery monodisperse silica microspheres (MNSP-2) were obtained.

[0054] (2) Disperse dicyandiamide, MNSP-2, and urea in water at a mass ratio of 1:0.5:1.5, stir for 30 minutes to mix evenly, dry in an oven at 60°C, grind, and collect the white powder for later use.

[0055] (3) Put the obtained powder into a tube furnace protected by nitrogen gas, and heat at 2°C·min -1 Raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com