Preparation method of a single-layer carbon nitride composite zinc ferrite z-type catalyst and its nitrogen fixation application

A technology of carbon nitride and zinc ferrite, which is applied in physical/chemical process catalysts, chemical instruments and methods, preparation/separation of ammonia, etc. It can solve problems such as narrow visible light response range and slow separation efficiency of photogenerated electrons and holes , to achieve the effect of simple operation and good photocatalytic nitrogen fixation and ammonia production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

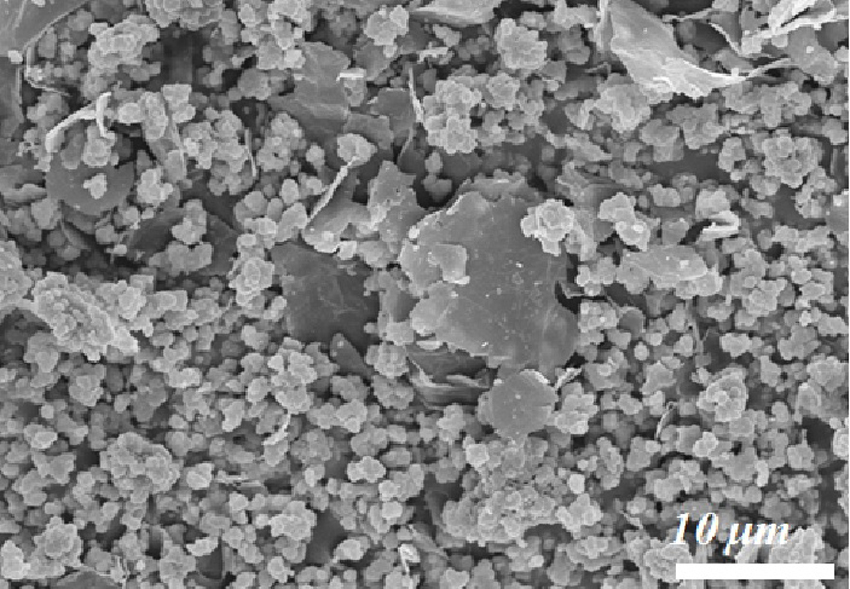

[0028] (1) Spread 2 g of dicyandiamide in a covered quartz crucible, and then at 10 ℃ min -1 The temperature was raised to 600 °C and heated for 2 h under the protection of nitrogen. After the reaction is completed, the sample is cooled to room temperature, and it is ground into a powder by an agate mortar g-C 3 N 4 ; Then 5 mg of prepared g-C will be taken 3 N 4 Added to 500 mL of methanol, ultrasonicated at 50 Hz for 1 h at room temperature, collected by centrifugation and dried at 60 °C for 12 h to obtain SL g-C 3 N 4 -1.

[0029] (2) Under stirring conditions, 100mg of the prepared SL g-C 3 N 4 -1 was added to 1000mL methanol, stirred for 0.5h; then 10.0 mg Zn(NO 3 ) 2 •6H 2 O and 27.2 mg Fe(NO 3 ) 3 •9H 2 O, after continuing to stir for 1 hour, adjust the pH of the dispersion to 7 by adding ammonia water dropwise; then transfer the mixture to a high-temperature and high-pressure reactor, and react for 8 hours at 120°C; The obtained product was washed three t...

Embodiment 2

[0032] (1) Spread 2 g of dicyandiamide in a covered quartz crucible, and then at 10 ℃ min -1 The temperature was raised to 600 °C and heated for 2 h under the protection of nitrogen. After the reaction is completed, the sample is cooled to room temperature, and it is ground into a powder by an agate mortar g-C 3 N 4 ; Then 25 mg of prepared g-C will be taken 3 N 4 Added to 500 mL ethanol, ultrasonicated at 60 Hz for 2 h at room temperature, collected by centrifugation and dried at 60 °C for 12 h to obtain SL g-C 3 N 4 -2.

[0033] (2) Under stirring conditions, 100mg of the prepared SL g-C 3 N 4 -2 was added to 500mL ethanol, stirred for 2h; then 14.98 mg Zn(NO 3 ) 2 •6H 2 O and 22.1 mg Fe(NO 3 ) 3 •9H 2 O, after continuing to stir for 4 hours, adjust the pH value of the dispersion to 8 by adding ammonia water dropwise; then transfer the mixed solution to a high-temperature and high-pressure reactor, and react for 12 hours at 140°C; The obtained product was washe...

Embodiment 3

[0036] (1) Spread 2 g of dicyandiamide in a covered quartz crucible, and then at 10 ℃ min -1 The temperature was raised to 600 °C and heated for 2 h under the protection of nitrogen. After the reaction is completed, the sample is cooled to room temperature, and it is ground into a powder by an agate mortar g-C 3 N 4 ; Then take 50 mg of prepared g-C 3 N 4 Added to 500 mL of ethylene glycol, ultrasonicated at 80 Hz for 4 h at room temperature, collected by centrifugation and dried at 60 °C for 12 h to obtain SL g-C 3 N 4 -3.

[0037] (2) Under stirring conditions, 100mg of the prepared SL g-C 3 N 4 -3 was added to 200mL ethylene glycol, stirred for 8h; then 20.05 mg Zn(NO 3 ) 2 •6H 2 O and 17.1 mg Fe(NO 3 ) 3 •9H 2 O, after continuing to stir for 8 hours, adjust the pH value of the dispersion to 10 by adding ammonia water dropwise; then transfer the mixed solution to a high-temperature and high-pressure reactor, and react for 16 hours at 160°C; The obtained produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com