Light-driven oil absorption MXene modified melamine sponge and preparation method thereof

A melamine sponge, light-driven technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of reduced oil absorption capacity and repeated use performance, and high energy consumption of sponge materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

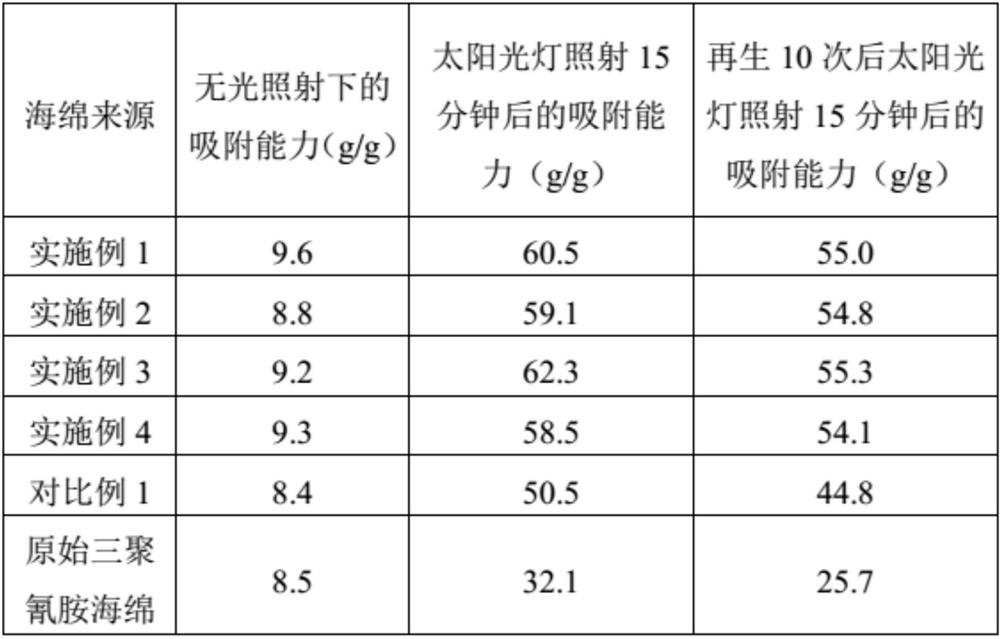

Examples

Embodiment 1

[0016] 1) Mix 0.05g MXene, 0.1g polydimethylsiloxane, and 60mL ethyl acetate evenly to obtain solution A, and soak the melamine sponge in solution A for 3h;

[0017] 2) Transfer the sponge-solution A mixture in step 1) to a hydrothermal reactor, heat to 150° C. for insulation reaction for 2 hours, cool to room temperature and take out the sponge;

[0018] 3) placing the melamine sponge obtained in step 2) in an oven, and curing at 60° C. for 3 hours to obtain an MXene-modified melamine sponge.

Embodiment 2

[0020] 1) First mix 0.1g of MXene, 0.2g of polydimethylsiloxane, and 80mL of butyl acetate to obtain solution A, and then soak the melamine sponge in solution A for 2 hours;

[0021] 2) Transfer the sponge-solution A mixture in step 1) into a hydrothermal reaction kettle, heat it to 140° C. for an insulation reaction for 3 hours, cool it to room temperature and take it out;

[0022] 3) The melamine sponge obtained in step 2) is placed in an oven, and cured at 65° C. for 3 hours to obtain an MXene-modified melamine sponge.

Embodiment 3

[0024] 1) First mix 0.05g MXene, 0.3g polydimethylsiloxane, and 80mL ethyl acetate to obtain solution A, and then soak the melamine sponge in solution A for 4h;

[0025] 2) Transfer the sponge-solution A mixture in step 1) into a hydrothermal reaction kettle, heat it to 150° C. for insulation reaction for 2 hours, and take it out after cooling to room temperature;

[0026] 3) The melamine sponge obtained in step 2) was placed in an oven, and was cured at 60° C. for 4 hours to obtain an MXene modified melamine sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com