Long-stator linear motor structure for maglev train and maglev train

A technology for linear motors and maglev trains, applied in the shape/style/structure of magnetic circuits, the shape/style/structure of winding conductors, motor vehicles, etc., can solve the impact of thrust and suspension force fluctuations, does not involve double-fed motor design, There are no effective technical measures to achieve the effects of improving reliability, improving mechanical and thermodynamic properties, improving stiffness and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

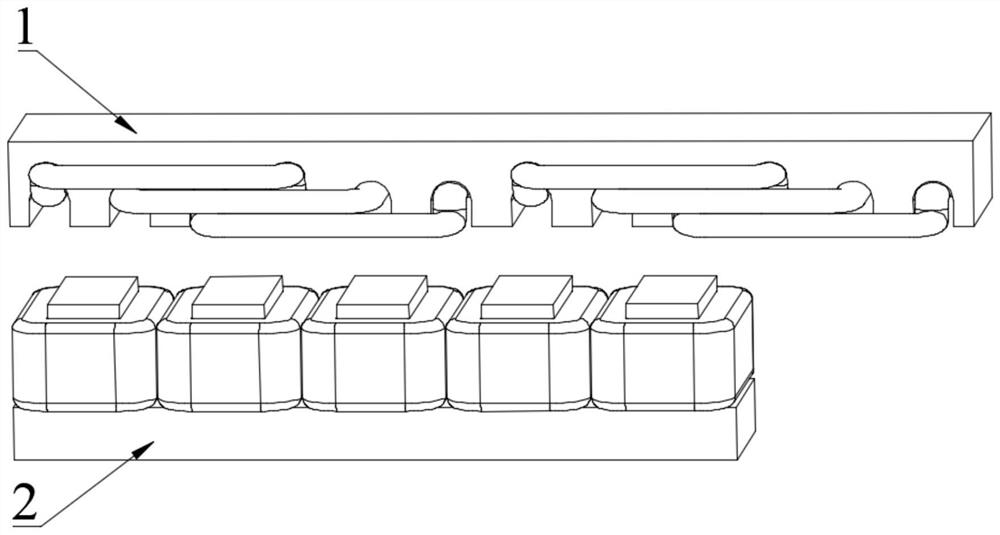

[0042] Such as figure 1 As shown, this embodiment provides a long-stator linear motor structure for a maglev train, including two linear motors arranged opposite to each other on the left and right sides. The figure schematically shows a stator 1 with twelve slots and four poles and a mover 2 with five slots and three poles.

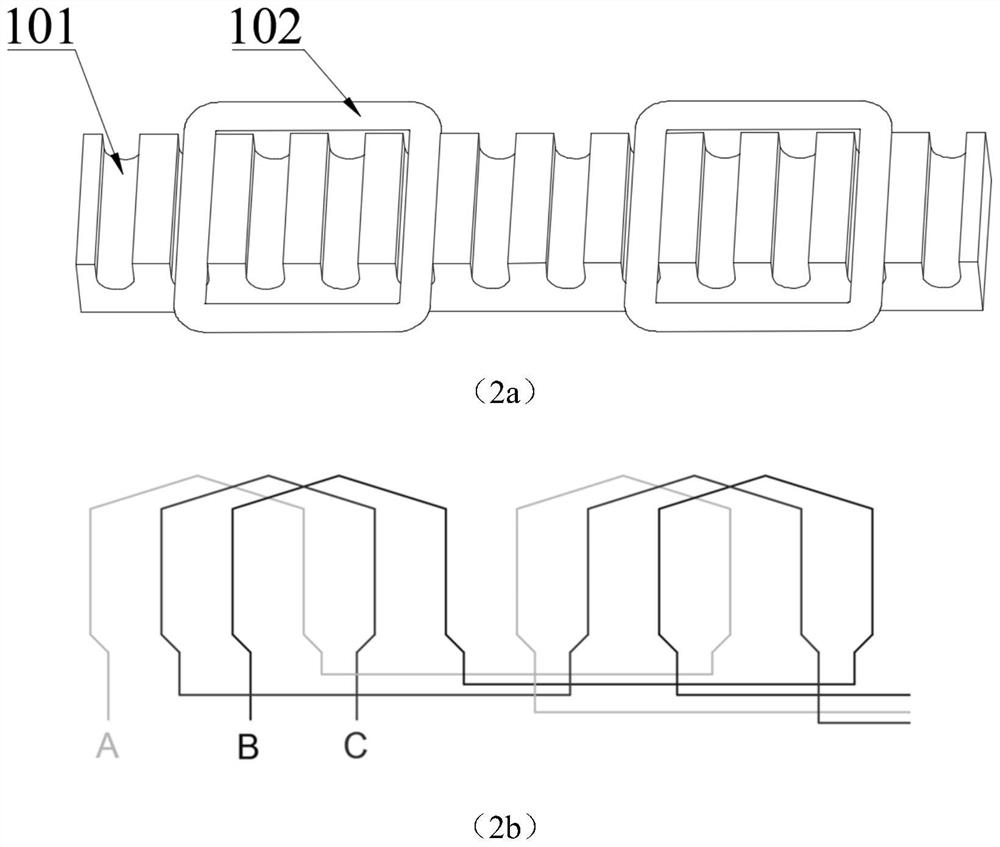

[0043] Such as figure 2 As shown, a pair of poles of the stator 1 has a six-slot, single-layer, single-turn, integer-slot, and wave winding structure. The stator 1 includes a stator core, and the stator core is provided with a round-bottomed open slot 101 , and a single-layer wave winding 102 is embedded in the open slot 101 . The pole moment is 258mm, and the tooth width is 43mm.

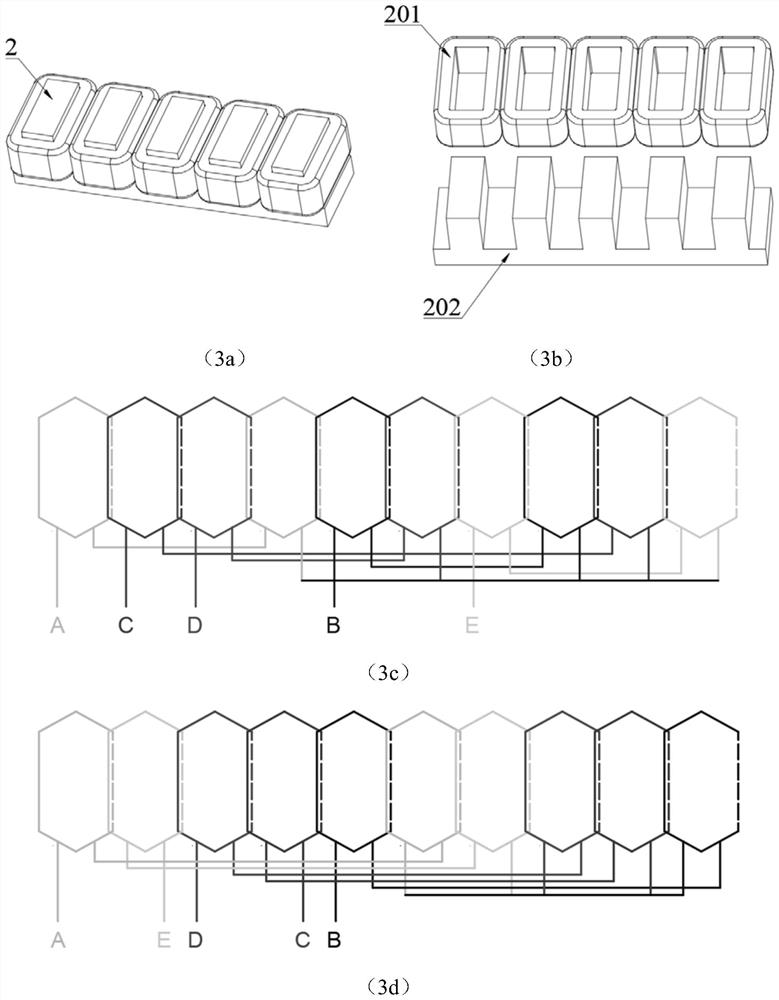

[0044] Such as image 3 As shown, each unit motor of the mover 2 has a 10-slot, 6-pole structure, double-layer, multi-turn, fractional slot, and concentrated winding structure. The winding adopts five-phase star connection, the number of turns is 270 turns, the pole mom...

Embodiment 2

[0052] Refer to the pole slot design of Example 1.

[0053] The mover 2 includes a mover iron core, and the mover iron core is provided with a chute 202 , and a double-layer concentrated winding 201 is arranged in the chute 202 . The chute at the relative position of the mover iron cores on the left and right sides can be in a "V" shape, such as Figure 5 As shown, it can also be inverted "V" shape, such as Figure 6 shown. Under normal operating conditions, the axial forces on the left and right sides are equal in magnitude and opposite in direction; when the mover is axially offset, the originally balanced axial electromagnetic force component is no longer balanced and produces a force proportional to the axial offset. The proportional normalizing force component keeps the mover running along the design axis.

[0054] Figure 5 Axial offset for alignment of stator and mover outside. Outer alignment is adopted, and the chute at the relative position of the mover core on ...

Embodiment 3

[0065] This embodiment provides a maglev train, including the long-stator linear motor structure described in Embodiment 1 or Embodiment 2, wherein the stator is laid along a track, and the mover is fixed to the train.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com