Lithium-sulfur battery electrolyte, preparation method thereof and lithium-sulfur battery

A lithium-sulfur battery and electrolyte technology, applied in the field of lithium-sulfur battery electrolyte, can solve the problem that the electrolyte cannot meet the different needs of polysulfides at the same time, achieve good cycle life and coulombic efficiency, prolong cycle life, and ensure specific energy advantage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

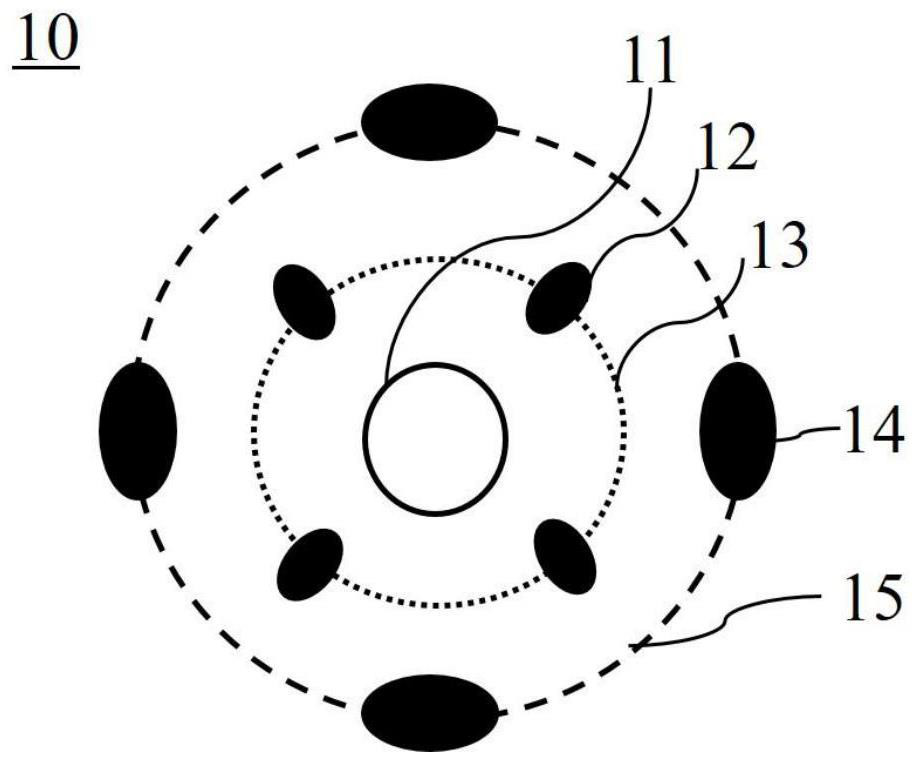

[0074] Preparation method of lithium-sulfur battery electrolyte

[0075] On the other hand, the present application also proposes a method for preparing an electrolyte solution for lithium-sulfur batteries, which may include the following steps: adding lithium salt and additives to the solvent of the dissolution layer under stirring conditions to obtain a solution; adding the solution to the encapsulation layer Solvent, prepared lithium-sulfur battery electrolyte.

[0076] It is understandable that in order to fully dissolve the lithium salt and additives, it is necessary to add the lithium salt and additives to the solvent of the dissolution layer at room temperature, stir until they are completely dissolved, and finally add them to the solvent of the encapsulation layer, and shake until they are completely miscible. Obtain the lithium-sulfur battery electrolyte.

[0077] The preparation method of the lithium-sulfur battery electrolyte according to the embodiment of the presen...

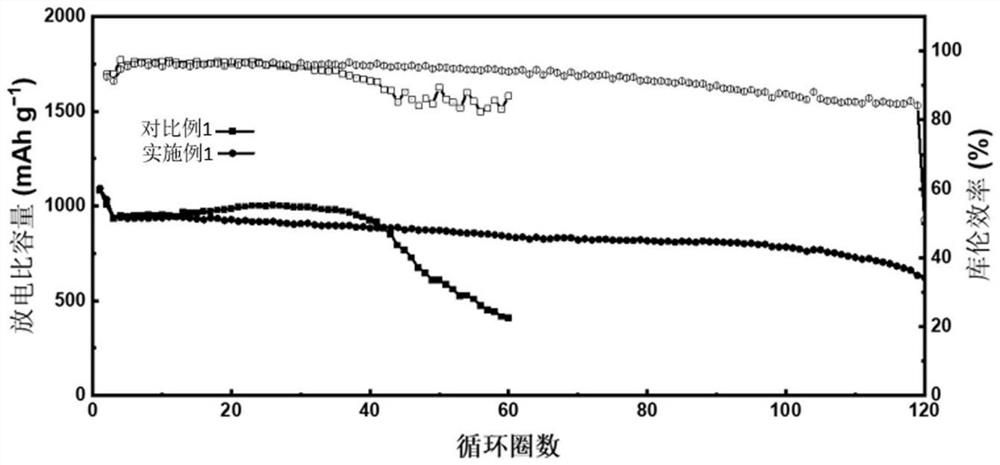

Embodiment 1

[0087] The lithium-sulfur battery electrolyte provided in this example includes the following components: the solvent for the dissolving layer is ethylene glycol dimethyl ether and 1,3-dioxolane, and the solvent for the encapsulation layer is 1,1,2,2-tetrafluoroethyl Base-2,2,3,3-tetrafluoropropyl ether, the volume ratio of the above three substances is 2:2:1; the lithium salt is lithium bis(trifluoromethylsulfonyl)imide, and the concentration is 1.0mol / L; The additive is lithium nitrate, and the mass fraction is 2%.

[0088] Take 35 μL of the above lithium-sulfur battery electrolyte with a loading capacity of 4.2 mg cm -2 The positive electrode sulfur and the negative electrode lithium sheet with a thickness of 50 μm are assembled into a lithium-sulfur battery in an argon atmosphere. The constant current charge and discharge test was carried out on the full battery, pre-cycle 2 laps at 0.05C, and then cycle at 0.1C. When the specific capacity decays to 70% of the initial s...

Embodiment 2

[0090] The lithium-sulfur battery electrolyte provided in this embodiment includes the following components: the solvent for the dissolving layer is ethylene glycol dimethyl ether and 1,3-dioxolane, and the solvent for the encapsulating layer is bis(2,2,2-trifluoroethyl base) ether, the volume ratio of the above three substances is 2:2:1; the lithium salt is lithium bis(trifluoromethylsulfonyl)imide, and the concentration is 1.0mol / L; the additive is lithium nitrate, and the mass fraction is 2 %.

[0091] Take 35 μL of the above lithium-sulfur battery electrolyte with a loading capacity of 4.2 mg cm -2 The positive electrode sulfur and the negative electrode lithium sheet with a thickness of 50 μm are assembled into a lithium-sulfur battery in an argon atmosphere. The constant current charge and discharge test was carried out on the full battery, pre-cycle 2 laps at 0.05C, and then cycle at 0.1C. When the specific capacity decays to 70% of the initial specific capacity at 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com