Multifunctional metal material detection device

A technology of metal materials and detection devices, applied in the direction of measuring devices, mechanical measuring devices, analyzing materials, etc., can solve the problem of simultaneous detection of the weight and hardness of metal materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

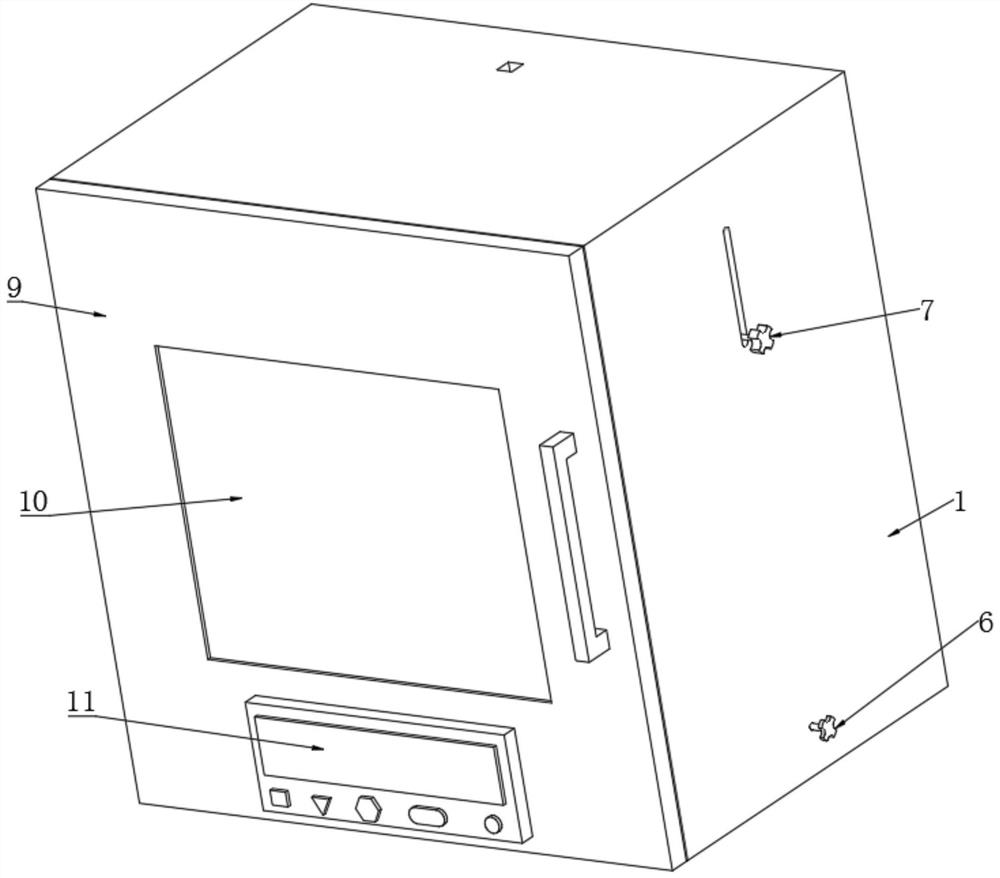

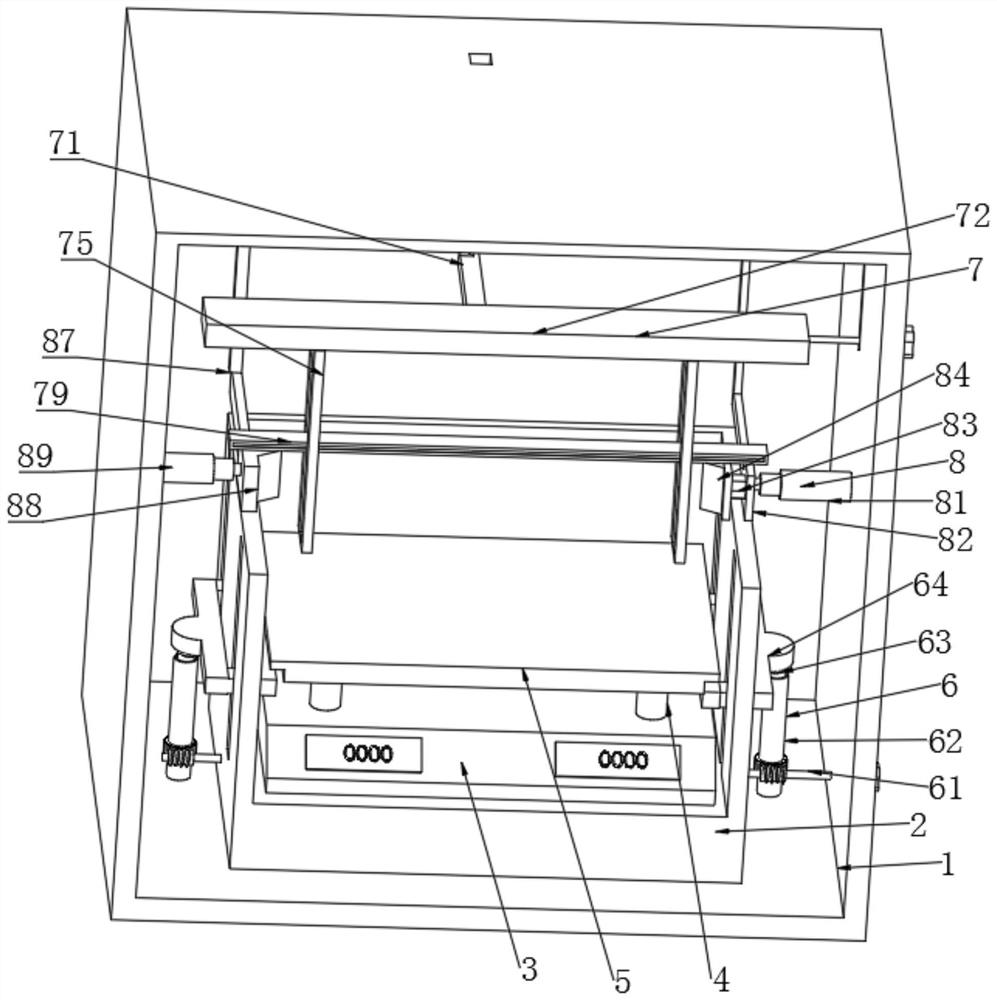

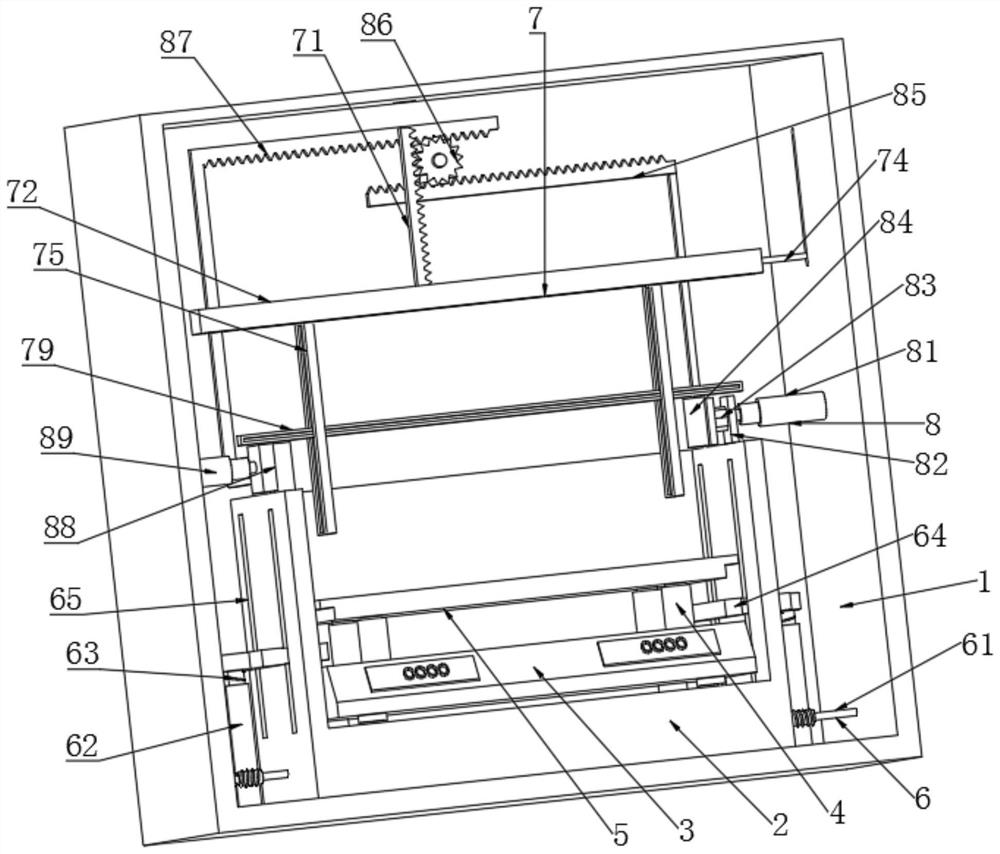

[0028] A multifunctional metal material detection device, comprising a detection box 1, a baffle plate 2 is fixedly connected to the bottom of the inner cavity of the detection box 1, an electronic scale 3 is fixedly connected to the bottom of the inner cavity of the baffle plate 2, and a sleeve is fixedly connected to the upper end of the electronic scale 3 4. The inner cavity of the sleeve 4 is slidingly connected with the tray 5. The inner cavity of the detection box 1 is installed with a lifting device 6 on both sides of the baffle 2. The inner cavity of the detection box 1 is installed with a measuring device 7 above the baffle 2. The detection box 1 Extrusion devices 8 are installed on both sides of the inner cavity wall, and the front end of the detection box 1 is connected to the box door 9 through hinge rotation. The middle part of the box door 9 is provided with an observation window 10, and one side of the box door 9 is located below the observation window 10. A cont...

Embodiment 2

[0029]Embodiment 2: The difference between this implementation and Embodiment 1 is that the extrusion device 8 consists of an electric telescopic rod 81, a mounting plate 82, a pressure sensor 83, a first extrusion plate 84, a first rack 85, and a transmission gear 86. , the second rack 87, the second extruding plate 88 and telescopic rod 89, one side of the cavity wall of the detection box 1 is fixedly connected with an electric telescopic rod 81, and one side of the electric telescopic rod 81 is fixedly connected with a mounting plate 82. One side of the mounting plate 82 is fixedly connected with a pressure sensor 83, one side of the pressure sensor 83 is fixedly connected with a first extrusion plate 84, one side of the mounting plate 82 is fixedly connected with a first rack 85, and the first rack 85 is connected to the transmission gear 86. Mesh connection. One side of the inner cavity wall of the detection box 1 is connected with a transmission gear 86 through a pin sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com