RST circulating thickening and emission reduction heat treatment equipment and system

A technology for heat exhaust treatment and waste gas treatment equipment, which is applied in the direction of lighting and heating equipment, combustion types, incinerators, etc., which can solve the problems of large exhaust gas emissions, increased operating costs, and increased load on waste gas treatment equipment, so as to reduce load and improve Efficiency, to achieve the effect of saving energy and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

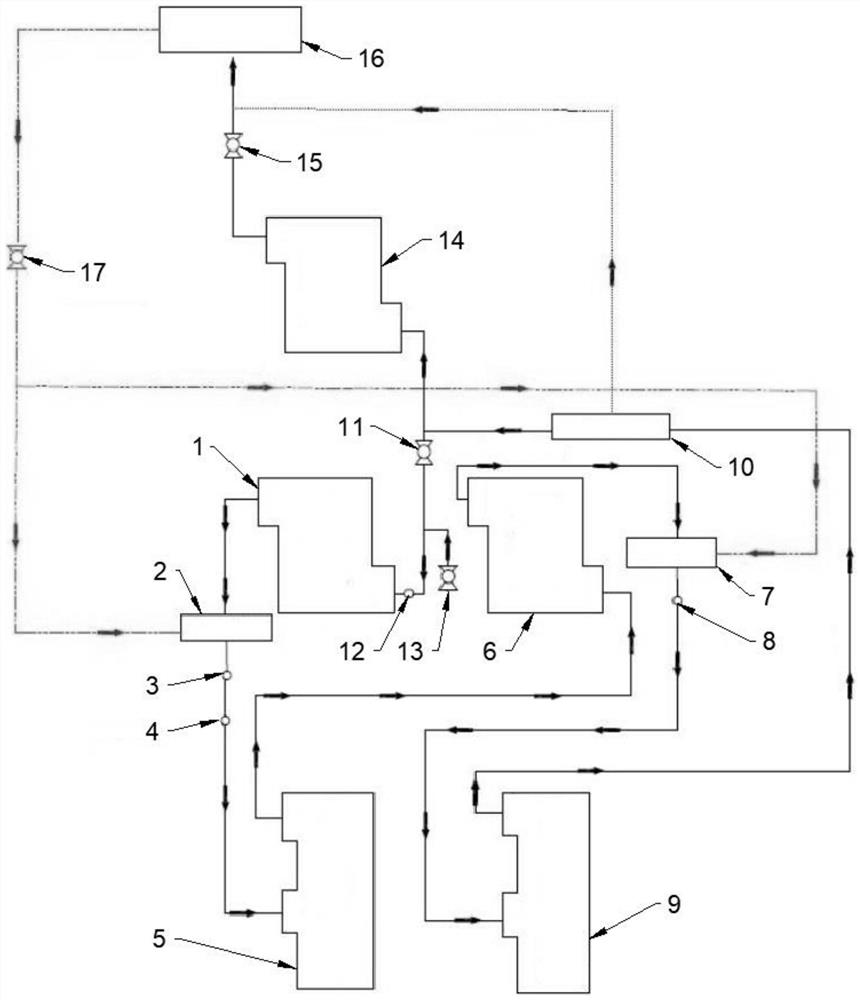

[0034] An RST cycle heat treatment equipment for increasing concentration and reducing emission can truly increase the concentration and reduce emission of VOCs organic waste gas in the thermal oven of printing machines, better improve the efficiency of waste gas treatment equipment, and realize energy saving and consumption reduction, such as figure 1 As shown, specifically set to the following structure:

[0035] This kind of heat treatment equipment for increasing concentration and reducing emission of RST cycle includes a first fan 1, a first color group heat oven 5, a second fan 6, a second color group heat oven 9, a second valve 11, a first valve 13, and a third fan 14. The third valve 15 and the exhaust gas treatment equipment 16.

[0036] The specific connection method is: the air outlet and the air inlet of the first fan 1 are respectively connected to the air inlet of the first color group heat oven 5 and the air outlet of the second valve 11 through a pipeline, and...

Embodiment 2

[0043] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

[0044] In this embodiment, this kind of RST cycle enrichment and emission reduction heat treatment equipment also includes a first heat exchange module 2 and a second heat exchange module 7, and both the first heat exchange module 2 and the second heat exchange module 7 adopt existing equipment, It generally includes a casing and a refrigerant passage and a heating medium passage arranged in the casing. The refrigerant channel of the first heat exchange module 2 is connected to the pipe from the air outlet of the first fan 1 to the air inlet of the first color group heating oven 5, so that the gas coming out of the air outlet of the first fan 1 can directly enter the first heat exchange Among the refrigerant passages of the modules 2, the heat medium passages of the first heat exc...

Embodiment 3

[0049] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

[0050] In this embodiment, the RST cycle enrichment and emission reduction heat treatment equipment further includes a first differential pressure sensor 12 and a second differential pressure sensor 4. The first differential pressure sensor 12 is installed at the pipe from the access point of the air outlet end of the first valve 13 to the air inlet of the first fan 1, and the second differential pressure sensor 4 is installed at the outlet of the refrigerant channel of the first heat exchange module 2 to At the duct of the air inlet of the first color group heat oven 5. The first differential pressure sensor 12 and the second differential pressure sensor 4 cooperate to monitor the gas pressure difference between the air inlet of the first fan 1 and the outlet of the refrigerant c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com