Method and system for preparing ethanol through efficient gas fermentation

A technology for producing ethanol and gas, applied in the field of high-efficiency gas fermentation to produce ethanol, can solve the problems of low water consumption per unit of ethanol concentration, etc., and achieve the effects of reducing water consumption and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

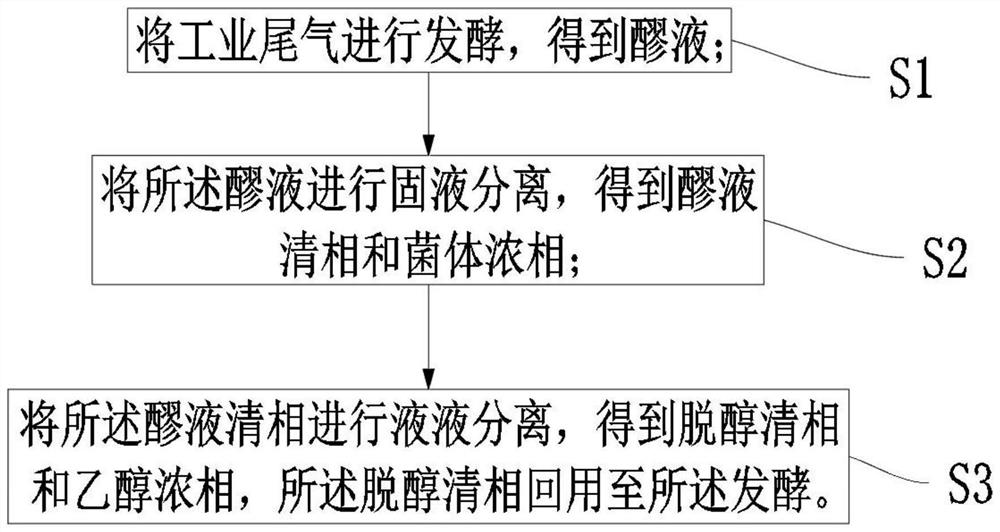

Image

Examples

Embodiment 1

[0065] The nutrient solution flow rate of the nutrient solution inlet of the fermentation device is 5m 3 / h, the raw gas intake at the raw gas inlet is 500Nm 3 / h, the volume of the fermentation device is 100m 3 , The concentration of ethanol in the mash is 30g / L, and the concentration of bacteria is 20g / L. The mash outlet flow rate of the fermentation unit is 20m 3 / h, the mash enters the centrifugal cell separation device, after concentration and separation, the concentration of the clear phase of the mash is 1g / L, and the flow rate is 16m 3 / h; the dense phase concentration of bacteria is 100g / L, and the flow rate is 4m 3 / h, of which 2m 3 The thick phase of the bacteria in / h is discharged from the system, and the remaining dense phase of the bacteria is recycled to the fermentation device to continue fermentation. The clear phase of the mash enters the crude distillation ethanol separation device to obtain 150g / L ethanol with a flow rate of 3m 3 / h, obtain the clear...

Embodiment 2

[0067] The nutrient solution flow rate of the nutrient solution inlet of the fermentation device is 8m 3 / h, the raw gas intake at the raw gas inlet is 500Nm 3 / h, the volume of the fermentation device is 100m 3 , The concentration of ethanol in the mash is 30g / L, and the concentration of bacteria is 20g / L. The mash outlet flow rate of the fermentation unit is 30m 3 / h, the mash enters the centrifugal cell separation device, after concentration and separation, the concentration of the clear phase of the mash is 1g / L, and the flow rate is 26m 3 / h; the dense phase concentration of bacteria is 100g / L, and the flow rate is 4m 3 / h, of which 2m 3 The thick phase of the bacteria in / h is discharged from the system, and the remaining dense phase of the bacteria is recycled to the fermentation device to continue fermentation. The clear phase of the mash enters the alcohol-permeable membrane separation device to obtain 75g / L ethanol with a flow rate of 6m 3 / h, obtain the dealco...

Embodiment 3

[0069] The nutrient solution flow rate of the nutrient solution inlet of the fermentation device is 10.6m 3 / h, the raw gas intake at the raw gas inlet is 500Nm 3 / h, the volume of the fermentation device is 100m 3 , The concentration of ethanol in the mash is 30g / L, and the concentration of bacteria is 20g / L. The mash outlet flow rate of the fermentation unit is 300m 3 / h, the mash enters the bacterial membrane separation device, after concentration and separation, the concentration of the clear phase of the mash is 0g / L, and the flow rate is 30m 3 / h; the dense phase concentration of bacteria is 22.2g / L, and the flow rate is 270m 3 / h, of which 9m 3 The thick phase of the bacteria in / h is discharged from the system, and the remaining dense phase of the bacteria is recycled to the fermentation device to continue fermentation. The clear phase of the mash enters the crude distillation ethanol separation device to obtain 150g / L ethanol with a flow rate of 1.6m 3 / h, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com