Liquid increasing device for washing wells

A liquid device and well-washing technology, which is applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of large damage, leakage of well-washing fluid, and oil layer pollution, so as to avoid well killing and increase output Fluid volume, effect of reducing pump leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

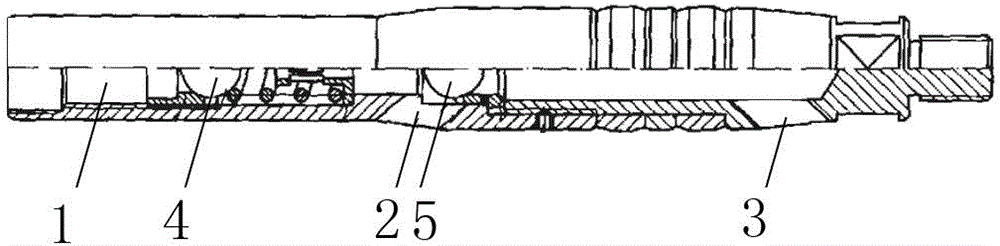

[0012] A liquid booster for well flushing according to the present invention comprises a body, the upper part of the body is provided with an upper liquid inlet hole 1, and the lower part of the upper liquid inlet hole 1 is provided with a liquid outlet hole 2, and the upper liquid inlet hole 1 and the liquid outlet hole 2 are connected to each other. Connected, the liquid inlet hole is provided with a liquid inlet ball valve 4, the liquid inlet ball valve 4 is arranged on the body through a spring, the liquid outlet hole 2 is provided with a ball valve chamber, and the inside of the ball valve chamber is provided with a movable ball valve 5, the ball valve The minimum cross-sectional diameter of the chamber is larger than the diameter of the ball valve.

[0013] The liquid booster for well flushing according to the present invention is installed at the lower part of the oil well pump. When flushing the well, first remove the plug of the oil pump, and the heated well flush flui...

Embodiment 2

[0015] This embodiment is basically the same as Embodiment 1, except that a lower liquid inlet hole 3 is provided at the lower part of the liquid outlet hole 2 in this embodiment, and the lower liquid inlet hole 3 and the liquid outlet hole 2 communicate with each other.

[0016] During normal oil pumping, the downstroke stage: the well fluid enters the device from the lower liquid inlet hole 3, the movable ball valve 5 moves upward under the impact of the well fluid, and the well fluid flows to the liquid outlet hole 2, and then enters the hollow sucker rod and the oil pipe. The annulus completes a liquid feeding process; the upstroke stage: the liquid feeding ball valve 4 is downward, which can effectively seal the upper liquid of the liquid booster of the well flusher. At the same time, with the completion of the upstroke, the well fluid sucked during the downstroke is pumped to the ground to complete a drainage process. During the entire swabbing process, the device divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com