Low-noise turning double-layer linear crossed belt sorting machine

A cross-belt sorting and low-noise technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of the same track movement of sorting cars and the aggravation of running stability problems, so as to avoid impact and improve operation Stability, the effect of reducing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

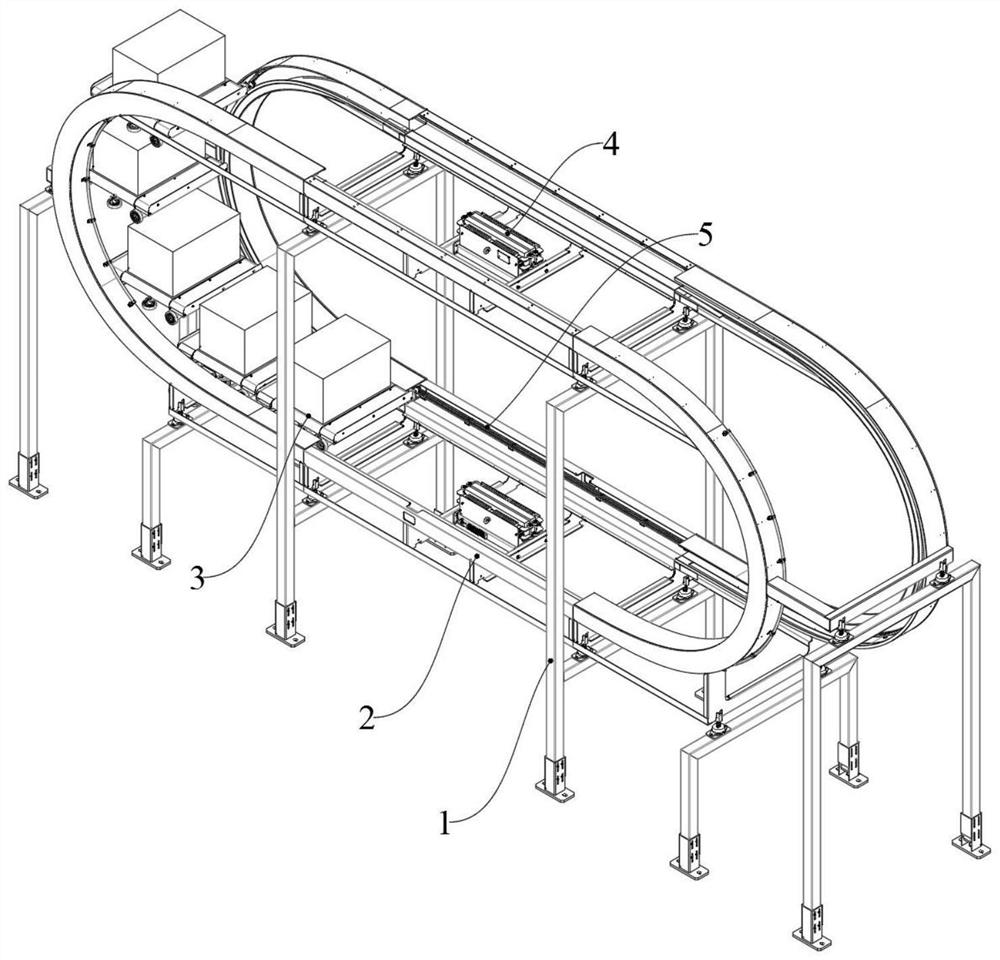

[0047] Such as figure 1 As shown, a double-layer linear cross-belt sorter with low noise and cornering, including a frame 1, a circular track 2, a plurality of sorting cars 3, a walking drive module 4, a car conveyor control component 5 and a car connection component 6. Ring track 2 is installed on the frame 1. A plurality of sorting trolleys 3 sequentially connected through the trolley connection assembly 6 are installed on the circular track 2 and driven by the travel driving module 4 . The power supply interface of the transverse conveyor 3 - 1 on the sorting trolley 3 is led to an external controller through the trolley conveyor control assembly 5 .

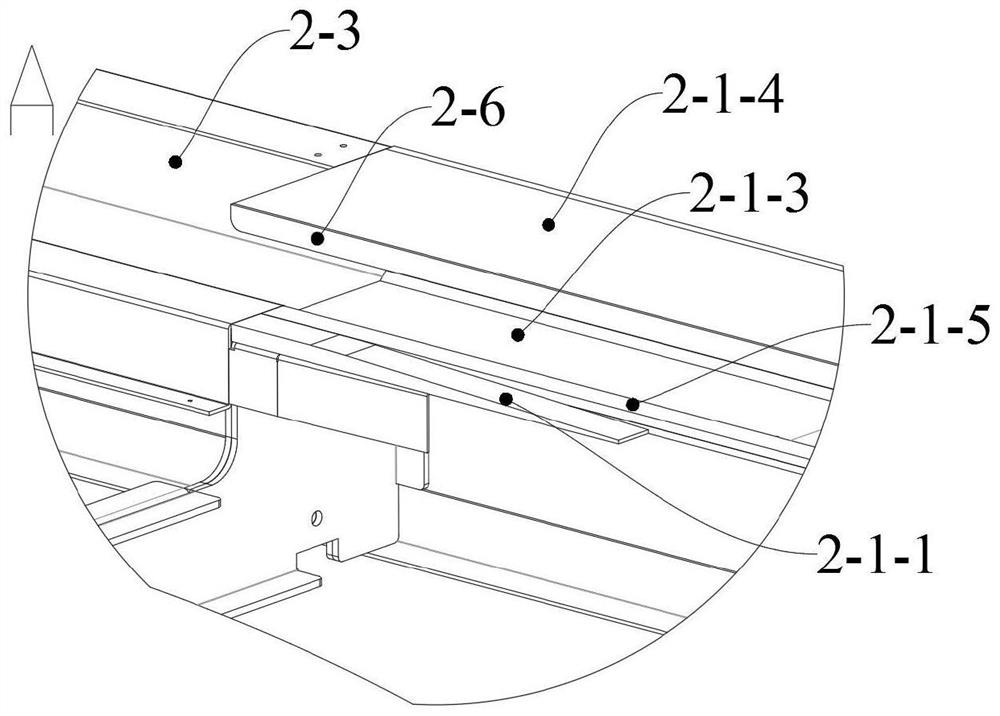

[0048] Such as figure 2 As shown, the circular track 2 includes two single-side tracks symmetrical to the center of the frame 1 . The single-side track comprises a long curved track 2-1, a short curved track 2-2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com