Multi-enzyme active metal-based cuttlefish ink melanin composite material and preparation method thereof

A technology of composite material and melanin, which is applied in the field of metal-based squid ink melanin composite material and its preparation, can solve problems such as limitations, and achieve the effects of low price, convenient operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

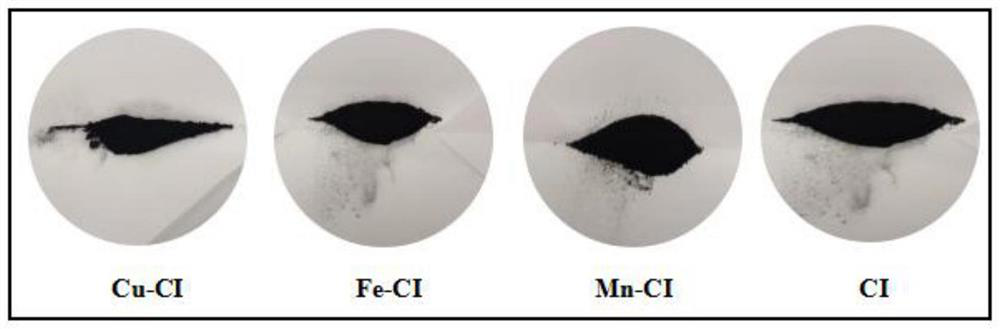

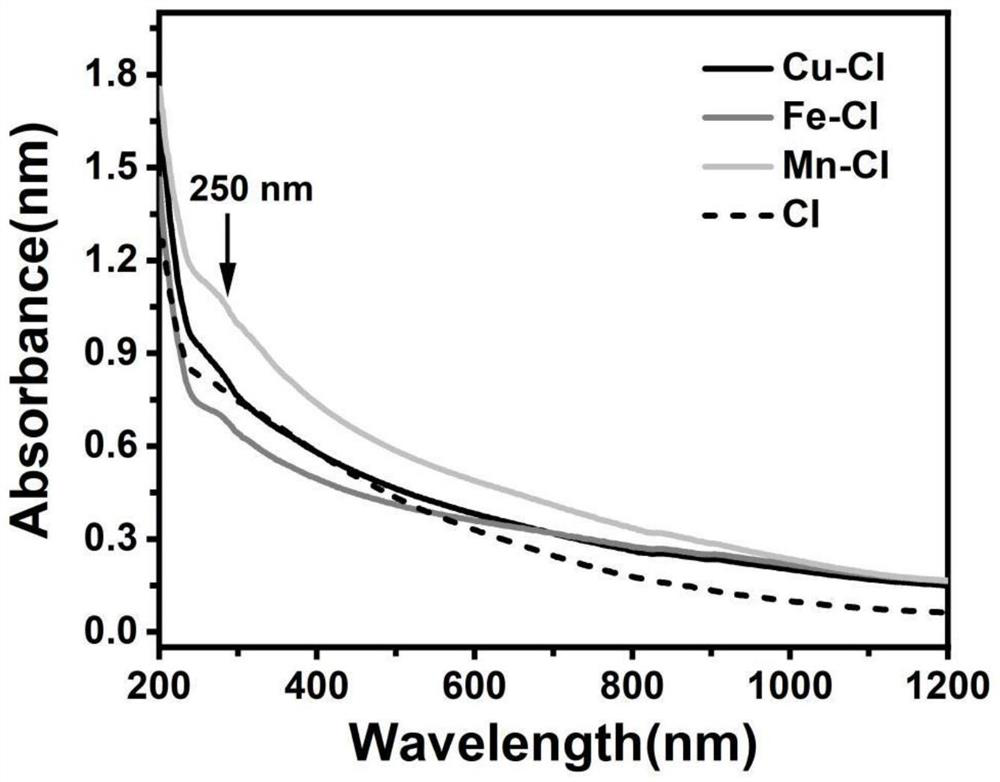

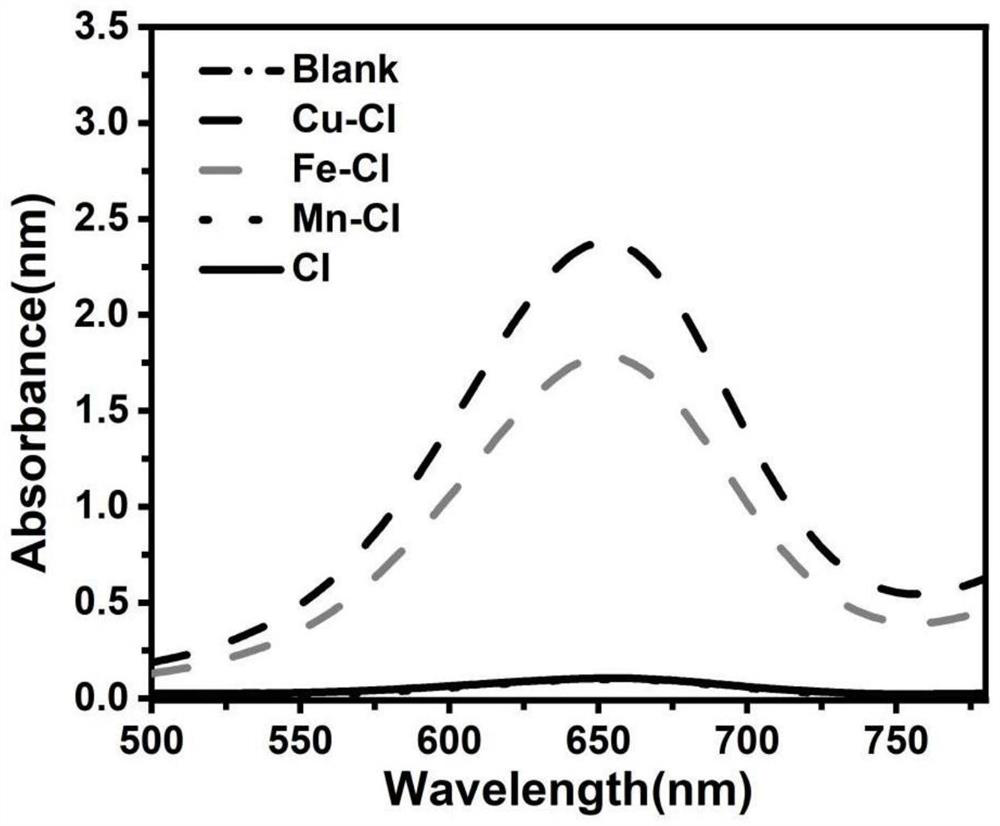

[0032] Preparation of Cu-doped composites with multi-enzyme activity using cuttlefish ink as raw material.

[0033] (1) Cut the cuttlefish ink sac and soak the ink sac juice in a solution of ethanol (95%) and water at a volume of 1:1 overnight to remove surface impurities. The precipitate was washed several times with deionized water, and then dried in an oven at 60° C. for 12 h. Take the dried cuttlefish juice melanin and crush it into powder with a wall breaking machine, and pass it through a 200-mesh sieve for use;

[0034] (2) Dissolve 5 g of pre-broken squid ink melanin after sieving in 50 mL of 1 mmol / L sodium hydroxide solution, heat to 80 ° C for 2 h; dialyze the cooled mixed solution, and then dialyze The mixture in the bag was centrifuged at 150r / min for 8mi, and the supernatant was dried in an oven at 60°C to obtain purified cuttlefish ink melanin.

[0035] (3) Doping: Disperse 0.5g of purified cuttlefish ink melanin in 10mmol / L Cu 2+ 100mmol / L sodium chloride sa...

Embodiment 2

[0037] Preparation of Fe-doped composites with multi-enzyme activity using cuttlefish ink as raw material.

[0038] (1) Cut the cuttlefish ink sac and soak the ink sac juice in a solution of ethanol (95%) and water at a volume of 1:1 overnight to remove surface impurities. The precipitate was washed several times with deionized water, and then dried in an oven at 60° C. for 12 h. Take the dried cuttlefish juice melanin and crush it into powder with a wall breaking machine, and pass it through a 200-mesh sieve for use;

[0039] (2) Dissolve 5 g of pre-broken squid ink melanin after sieving in 50 mL of 1 mmol / L sodium hydroxide solution, heat to 80 ° C for 2 h; dialyze the cooled mixed solution, and then dialyze The mixture in the bag was centrifuged at 150r / min for 8mi, and the supernatant was dried in an oven at 60°C to obtain purified cuttlefish ink melanin.

[0040] (3) Doping: disperse 0.5g of purified squid ink melanin in a solution containing 10mmol / LFe 3+100mmol / L sod...

Embodiment 3

[0042] Preparation of Mn-doped composites with multi-enzyme activity using cuttlefish ink as raw material.

[0043] (1) Cut the cuttlefish ink sac and soak the ink sac juice in a solution of ethanol (95%) and water at a volume of 1:1 overnight to remove surface impurities. The precipitate was washed several times with deionized water, and then dried in an oven at 60° C. for 12 h. Take the dried cuttlefish juice melanin and crush it into powder with a wall breaking machine, and pass it through a 200-mesh sieve for use;

[0044] (2) Dissolve 5 g of pre-broken squid ink melanin after sieving in 50 mL of 1 mmol / L sodium hydroxide solution, heat to 80 ° C for 2 h; dialyze the cooled mixed solution, and then dialyze The mixture in the bag was centrifuged at 150r / min for 8mi, and the supernatant was dried in an oven at 60°C to obtain purified cuttlefish ink melanin.

[0045] (3) Doping: disperse 0.5g of purified cuttlefish ink melanin in 10mmol / LMn 2+ 100mmol / L sodium chloride sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com