Preparation method of binder-free molecular sieve catalyst

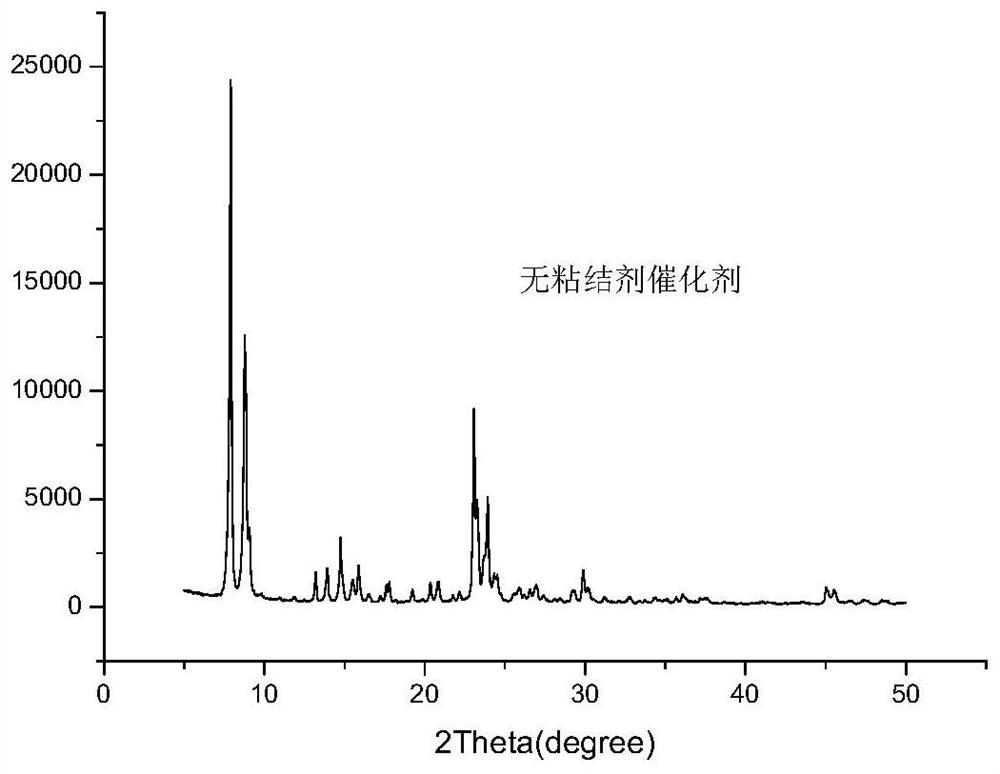

A binder-free, molecular sieve technology, applied in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve problems such as poor mechanical strength, achieve stable structure, complete transformation, and overcome poor mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a binder-free molecular sieve catalyst, the specific process comprising:

[0027] (1) Knead the original molecular sieve powder and the binder to obtain a molded body, and undergo the first drying (drying at 80-120°C for 5-10 hours) to obtain the catalyst precursor I; The amount of powder accounts for 20% to 80%, and the amount of binder accounts for 20% to 80%;

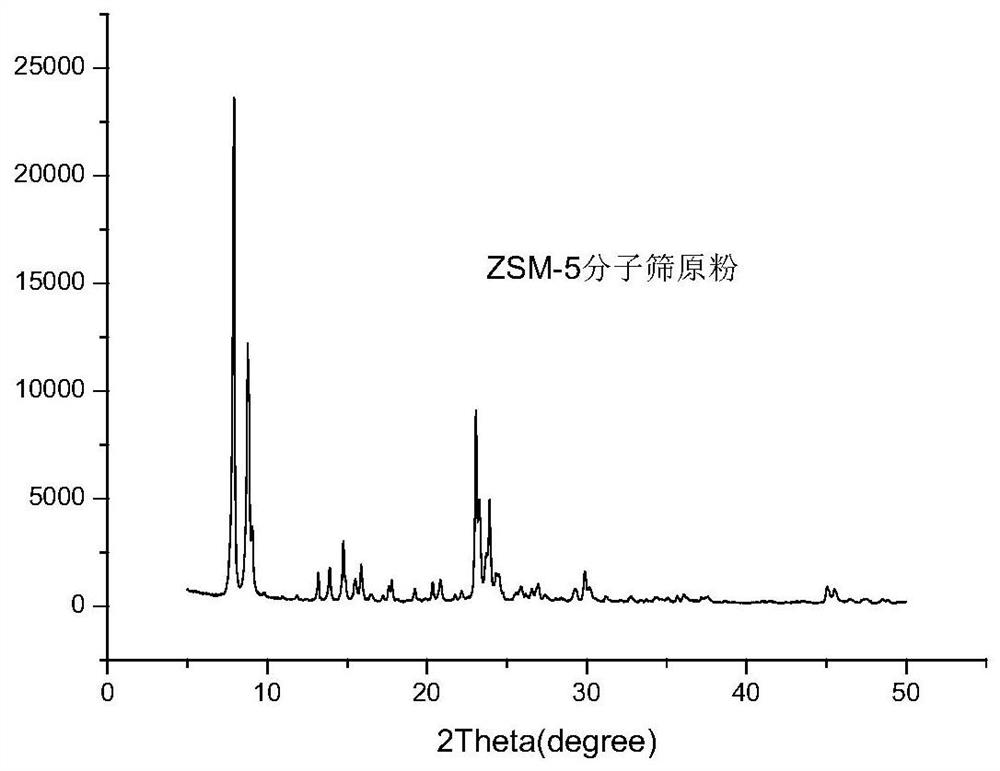

[0028] In the above technical solution, the molecular sieve is at least one of zeolite molecular sieves with FAU, MFI, CHA and MOR structures, preferably, the molecular sieve is at least one of ZSM-5 and MOR. The silicon-aluminum molar ratio SiO of described molecular sieve raw powder 2 / Al 2 o 3 10-1000, preferably 10-800. The binder used is selected from one or more of silica sol, water glass and alumina;

[0029] In the above technical solution, the molded body is columnar, the cross-section of the cylinder is circular, square, four-leaf clover, clover, rin...

Embodiment 1

[0040] 30 g SiO 2 / Al 2 o 3 Mole ratio is 100 ZSM-5 molecular sieves, 30 grams of silica sol (SiO 2 The mass content is 40%), kneaded, extruded into particles with a diameter of 0.4 cm, a length of 0.3-1.0 cm, and a circular cross section, and dried at 120° C. for 8 hours. Add 10 grams of 50% ethylamine aqueous solution into a closed reaction kettle, place the above-mentioned particle sample above the reaction kettle, and perform gas-solid treatment at 190° C. for 24 hours. After the product was taken out, it was dried at 120°C for 8 hours, and then calcined at 550°C for 4 hours in the air atmosphere of a muffle furnace to obtain a binder-free ZSM-5 molecular sieve. Add 100 grams of aqueous solution containing 3% ammonium acetate (mass content) and 1% acetic acid (mass content) mixture in a closed reactor, place 10 grams of the above-mentioned ZSM-5 molecular sieve catalyst in the reactor, heat to 70 ° C for 20 After taking out the product, wash it with distilled water, dr...

Embodiment 2

[0044] 30 g SiO 2 / Al 2 o 3 Mole ratio is 100 ZSM-5 molecular sieves, 30 grams of silica sol (SiO 2 The mass content is 40%), kneaded, extruded into particles with a diameter of 0.4 cm, a length of 0.3-1.0 cm, and a circular cross section, and dried at 120° C. for 8 hours. Add 10 grams of a mixed solution of triethylamine and water with a mass content of 50% in a closed reaction kettle, place the above-mentioned particle samples above the reaction kettle, and perform gas-solid treatment at 190° C. for 24 hours. After the product was taken out, it was dried at 120°C for 8 hours, and then calcined at 550°C for 4 hours in the air atmosphere of a muffle furnace to obtain a binder-free ZSM-5 molecular sieve. Add 100 grams of an aqueous solution containing a mixture of 0.2% ammonium acetate (mass content) and 0.1% acetic acid (mass content) in a closed reactor, place 100 grams of the above-mentioned ZSM-5 molecular sieve catalyst on the upper layer of the reactor, and heat it to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com