Composite material with zero-valent iron immobilized by biochar, preparation method of composite material and application of composite material in removal of tetracycline in water

A composite material, zero-valent iron technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as hindering the degradation rate of pollutants, reducing the contact area between ZVI and pollutants, and improving electron transfer. ability, the effect of promoting adsorption and contact area, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation steps of BC / ZVI composite materials are as follows: Weigh 1.0g hematite and 4.0g pine wood biomass (mass ratio 1:4) into a beaker, add 50mL deionized water, stir with a magnetic stirrer and then ultrasonicate for 30min to mix evenly. Centrifuge the homogeneous suspension and collect it in an oven at 60°C for drying, then take it out, pyrolyze the mixture in a tube furnace at 700°C for 1 hour, and inject 350mL min -1 Nitrogen is the protective carrier gas. The taken out BC / ZVI composites were washed three times with ethanol and deionized water respectively, and dried overnight in a vacuum oven at 60 °C.

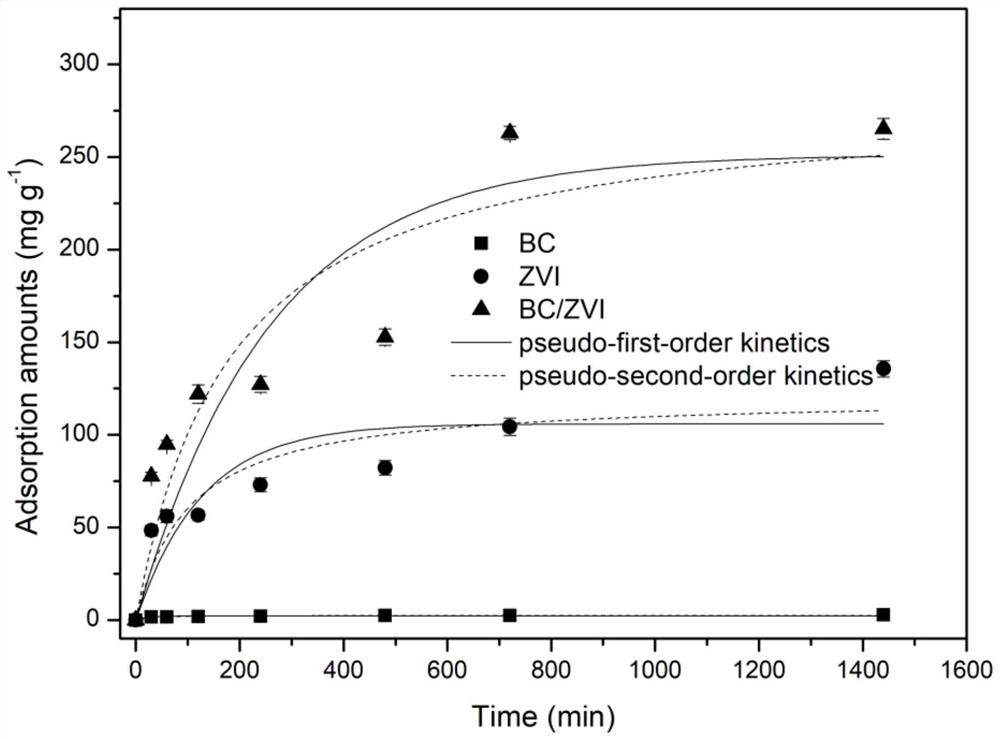

[0030] Add the prepared biochar-fixed zero-valent iron composite material into water containing tetracycline, and shake at a constant speed of 140rpm for more than 720min;

[0031] Further, EDTA at a concentration of 0.8 mM was added to the tetracycline-containing water.

[0032] Further, add 18 mg L to the water containing tetracycline -1 Ca 2+ . ...

Embodiment 2

[0034] The preparation steps of BC / ZVI composite material are as follows: Weigh 1.0g hematite and 6.0g pine wood biomass (mass ratio 1:6) into a beaker, add 50mL deionized water, stir with a magnetic stirrer and ultrasonicate for 30min to mix evenly. The homogeneous suspension was centrifuged and collected in an oven at 60°C, dried and taken out. The mixture was pyrolyzed in a tube furnace at 900°C for 1 hour, and 450 mL min was passed through the whole process. -1 Nitrogen is the protective carrier gas. The taken out BC / ZVI composites were washed three times with ethanol and deionized water respectively, and dried overnight in a vacuum oven at 60 °C.

[0035] Add the prepared biochar-fixed zero-valent iron composite material into water containing tetracycline, and shake at a constant speed of 160rpm for more than 720min;

[0036] Further, EDTA at a concentration of 1.2 mM was added to the tetracycline-containing water.

[0037] Further, add 22mg L to the water containing t...

Embodiment 3

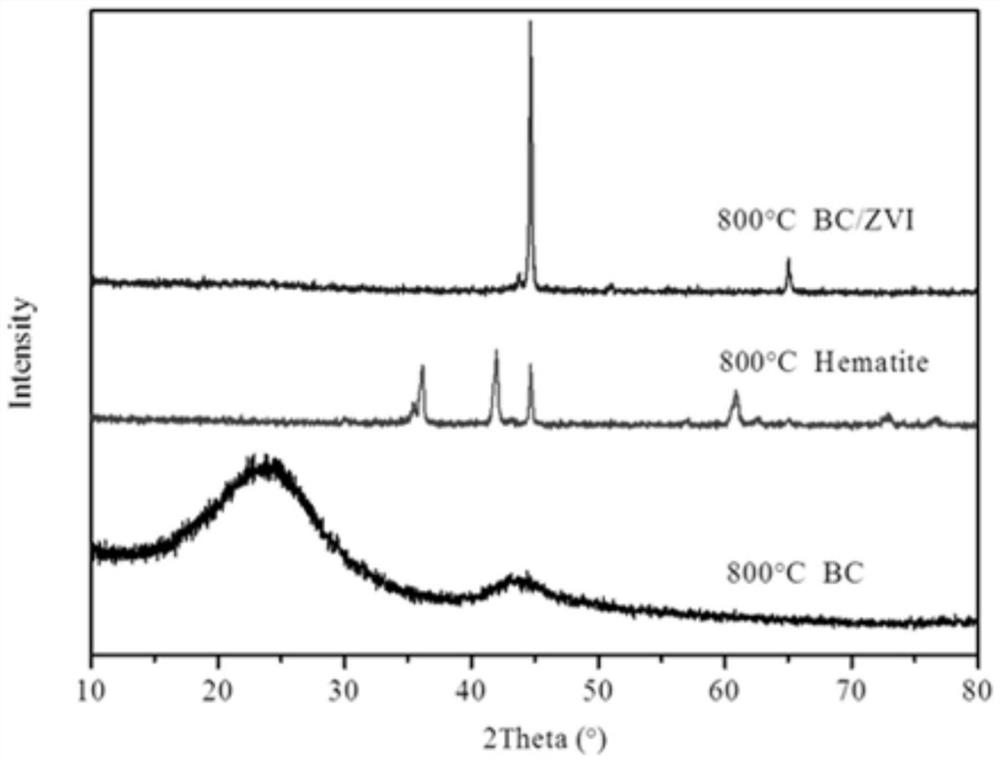

[0039] Preparation of BC / ZVI composites

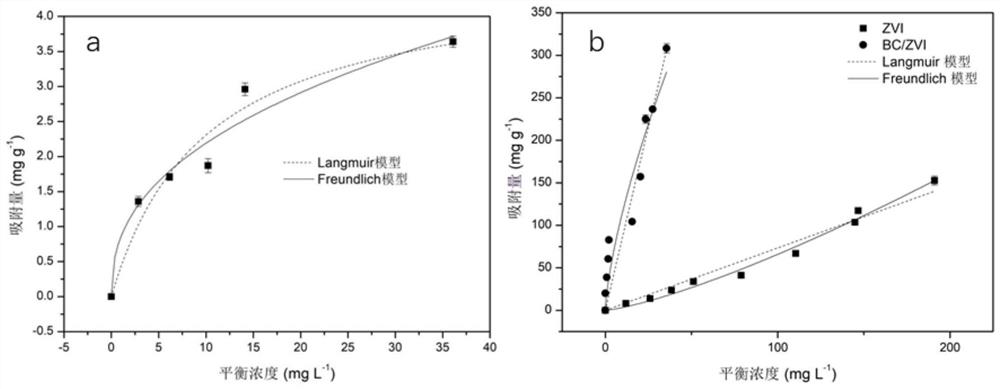

[0040] The specific steps of material preparation are: weigh 1.0g hematite and 5.0g pine wood biomass (pine wood biomass is collected from a local furniture processing factory, after using a particle crusher to pulverize) (mass ratio is 1:5) into a beaker, Add 50 mL of deionized water, stir with a magnetic stirrer and then sonicate for 30 min to mix evenly. The homogeneous suspension was centrifuged and collected in an oven at 60°C, dried and taken out. The mixture was pyrolyzed in a tube furnace at 800°C for 1 hour, and 400 mL min was passed through the whole process. -1 Nitrogen is the protective carrier gas. The taken out BC / ZVI composites were washed three times with ethanol and deionized water respectively, and dried overnight in a vacuum oven at 60 °C. At the same time, pure biochar was prepared by pyrolyzing pine biomass separately under the same conditions as a control treatment (BC); ferric chloride was reduced by sodium bor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com