Industrial binder for alumina ceramic material

A technology of alumina ceramics and binders, which is applied in the field of materials to achieve the effects of convenient bonding, easy degumming, and ensuring cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

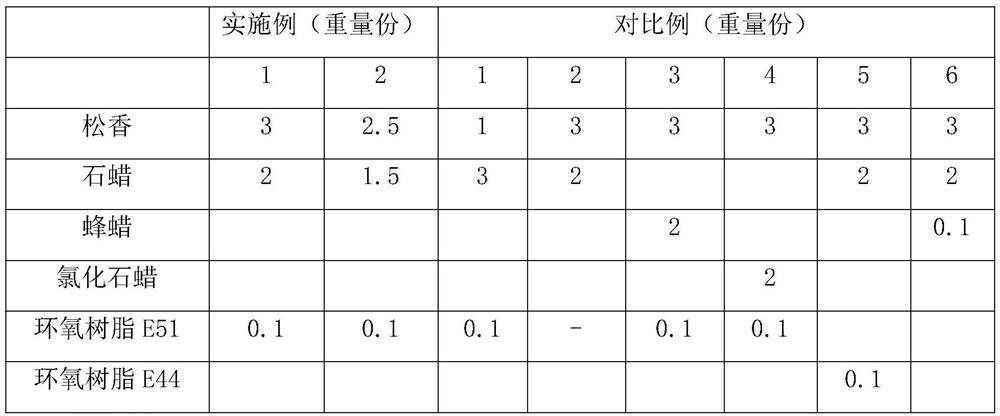

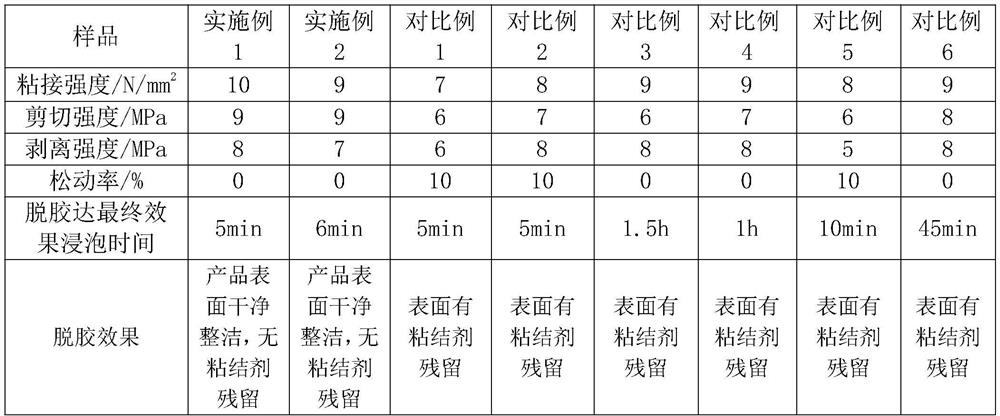

[0027] This embodiment relates to a kind of industrial binder, and its formula composition is shown in Table 1, and preparation method comprises the following steps:

[0028] Use rosin, industrial paraffin, and epoxy resin E51, weigh and configure according to the ratio of 3:2:0.1, put them all in an iron pot, heat for 30 minutes to 180°C to fully melt the three substances into a liquid state, at this time Stir evenly while heating. After stirring for 10 minutes, the three substances are fully dissolved. Take it down, place it in a cool place to cool for 45 minutes, put it in a paper cup, and cool it for 24 hours to become solid. When using, put the product and the bonding base (the product is Al 2 o 3 Ceramic material, base plate is Al 2 o 3 Ceramic materials) are placed on the heating plate at the same time, the temperature is set at 150°C, and heated for 20 minutes, because the adhesive will melt when heated, and then apply this adhesive evenly on the bonding base plate,...

Embodiment 2

[0031] This embodiment relates to a kind of industrial binder, and its formula composition is shown in Table 1, and preparation method comprises the following steps:

[0032] Use rosin, industrial paraffin, epoxy resin E51, weigh and configure according to the ratio of 2.5:1.5:0.1, put them all in an iron pot, heat for 30 minutes to 180°C to fully dissolve the three substances into a liquid state, at this time Stir evenly while heating. After stirring for 10 minutes, the three substances are fully dissolved. Take it down, place it in a cool place to cool for 45 minutes, put it in a paper cup, and cool it for 24 hours to become solid. When using, put the product and the bonding base (the product is Al 2 o 3 Ceramic material, base plate is Al 2 o 3 Ceramic materials) are placed on the heating plate at the same time, the temperature is set at 150°C, and heated for 20 minutes, because the adhesive will melt when heated, and then apply this adhesive evenly on the bonding base pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com