Rapid enrichment culture method of denitrifying phosphorus removal bacteria

A technology for denitrifying phosphorus removal bacteria and enrichment culture, which is applied in the field of rapid enrichment culture of denitrifying phosphorus removal bacteria, can solve the problems of long culture, slow establishment of denitrification phosphorus removal process, etc., achieves precise control process and realizes selection The effect of rapid proliferation and elimination of culture time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

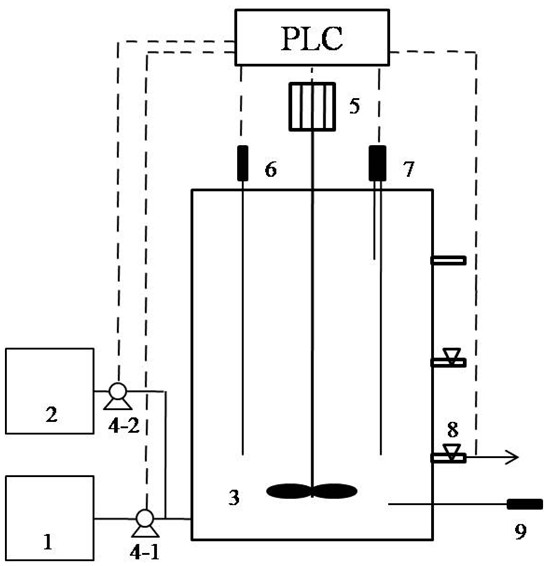

Method used

Image

Examples

Embodiment 1

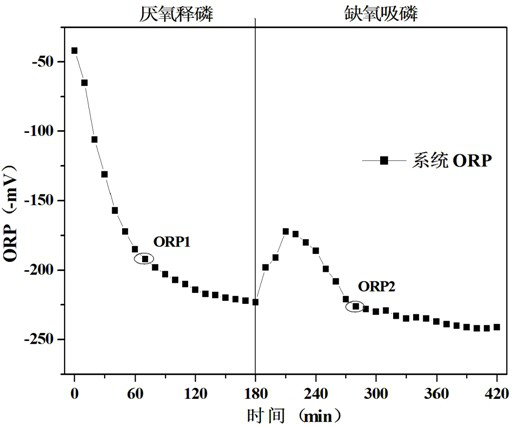

[0042] (1) Enhancement of sludge phosphorus removal performance and determination of ORP inflection point in culture system

[0043] Preparation of culture medium S1: COD and ammonia nitrogen concentrations were 200mg / L and 5.0mg / L respectively, prepared by NaAc and NH 4 Cl provided. At the same time, add CaCl 2 0.03g / L, MgSO 4 0.06g / L, FeSO 4 0.0012g / L, trace element nutrient solution 1.25g / L. Each liter of trace element nutrient solution contains EDTA (10g), FeCl 3 •6H 2 O (1.5g), ZnSO 4 •7H 2 O (0.12g), MnCl 2 • 4H 2 O (0.12g), H 3 BO 3 (0.15g), KI (0.18g), Na 2 MoO 4 • 2H 2 O (0.06g), CuSO 4 • 5H 2 O (0.03g), CoCl 2 •6H 2 O (0.15g). The pH is about 7.2.

[0044] Preparation of culture medium S2: NO 3 - -N concentration is 50mg / L, by NaNO 3 supply. Phosphorus concentration is added according to the same concentration of phosphorus in the culture solution at the end of the phosphorus release period, and the KH 2 PO 4 supply. Among them ammonia nitr...

Embodiment 2

[0055] Same as Example 1, the difference is that the concentrations of COD and ammonia nitrogen in culture solution S1 are 300 mg / L and 10 mg / L respectively, the concentration of nitrate nitrogen in culture solution S2 is 70 mg / L, and the concentration of P is 40 mg / L.

[0056] (1) Enhancement of sludge phosphorus removal performance and determination of ORP inflection point in culture system

[0057] The inflection point ORP1=-164mV is determined in the anaerobic stage, and the inflection point ORP2=-223mV is determined in the anoxic stage. When denitrification phosphorus removal bacteria accounted for 23% of all phosphorus removal bacteria, the sludge phosphorus removal performance enhancement process was completed.

[0058] (2) Cultivate denitrification and phosphorus removal bacteria

[0059] According to the ORP1 and ORP2 determined during the strengthening process, the PLC is set to start enriching denitrifying and phosphorus-removing bacteria. The culture medium used ...

Embodiment 3

[0062] Same as Example 1, except that the COD and ammonia nitrogen concentrations in the culture solution S1 are 100 mg / L and 3 mg / L respectively, the nitrate nitrogen concentration in the culture solution S2 is 50 mg / L, and the P concentration is 10 mg / L.

[0063] (1) Enhancement of sludge phosphorus removal performance and determination of ORP inflection point in culture system

[0064] The inflection point ORP1=-191mV is determined in the anaerobic stage, and the inflection point ORP2=-229mV is determined in the anoxic stage. When denitrification phosphorus removal bacteria accounted for 22% of all phosphorus removal bacteria, the sludge phosphorus removal performance enhancement process was completed.

[0065] (2) Cultivate denitrification and phosphorus removal bacteria

[0066] According to the ORP1 and ORP2 determined during the strengthening process, the PLC is set to start enriching denitrifying and phosphorus-removing bacteria. The culture medium used in the enrich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com