Device for testing dynamic characteristics of elastic ring type squeeze film damper

A technology of squeeze oil film damping and dynamic characteristics, which is applied in the field of aero-engines, can solve problems such as unknown installation status, inconvenient disassembly and assembly, and complex structure, and achieve the effects of simple structure, convenient disassembly and assembly, and verification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

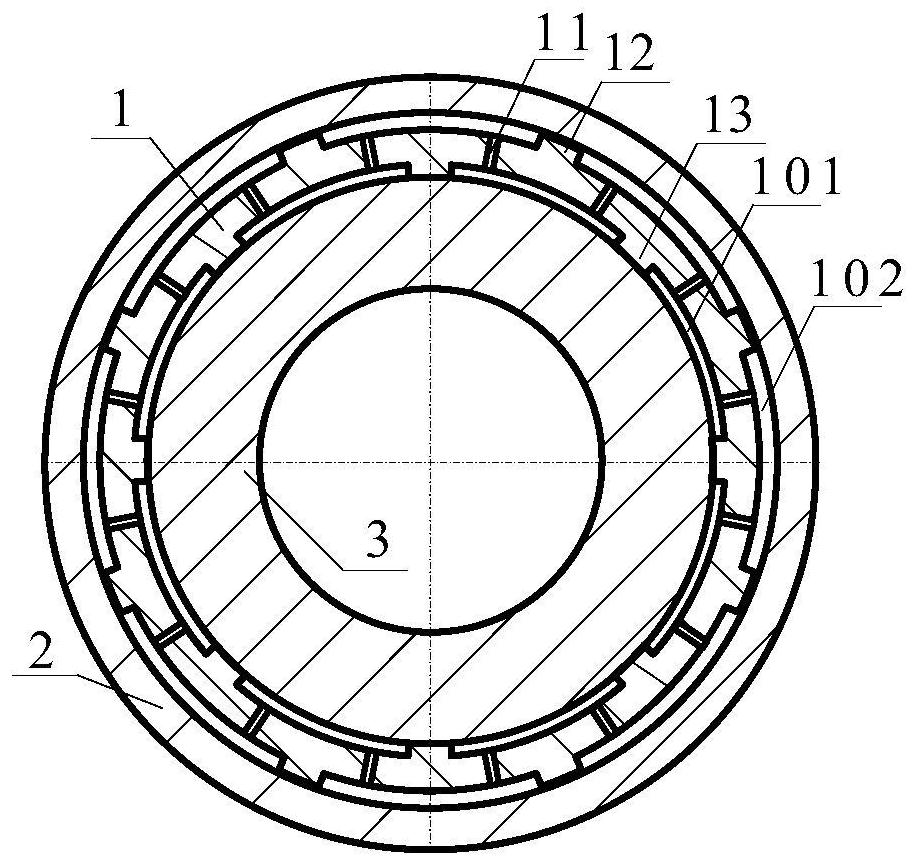

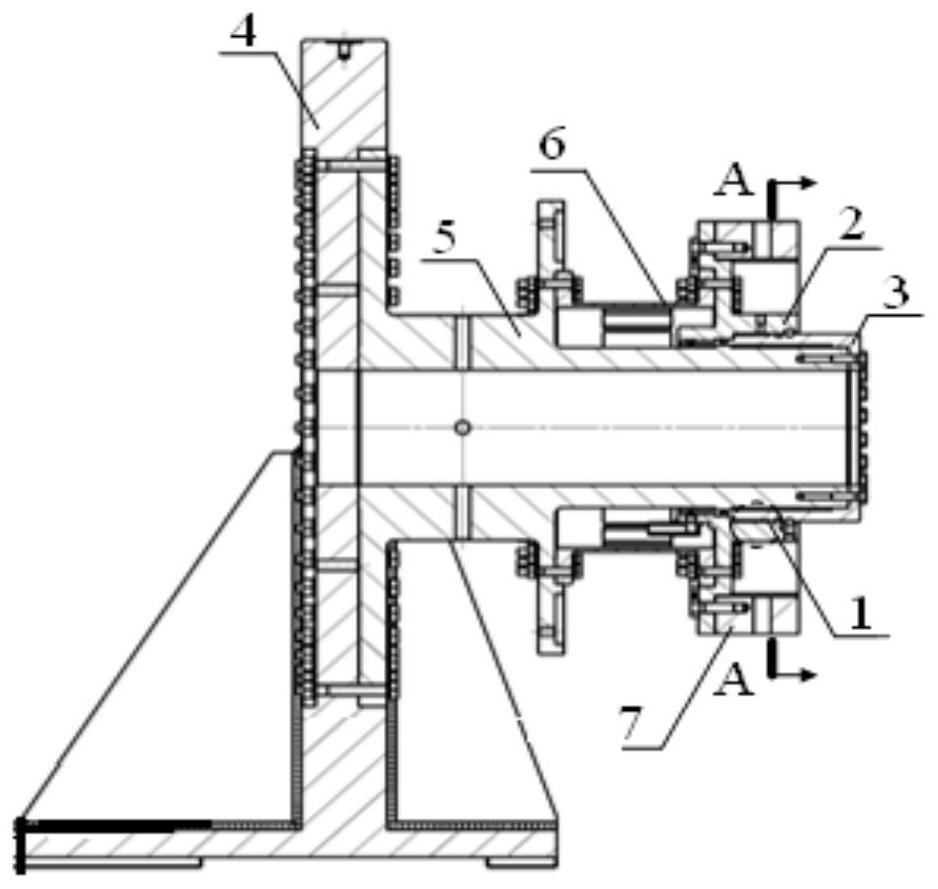

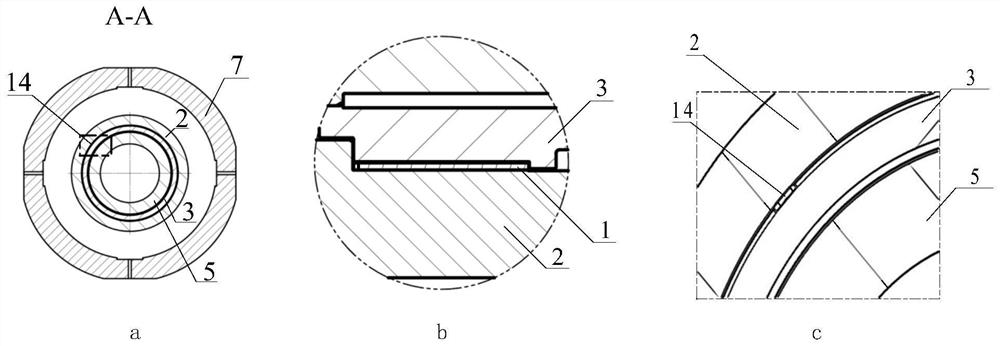

[0048] This embodiment is an experimental device for testing the dynamic characteristics of an elastic ring squeeze oil film damper, including an elastic ring 1, an outer bush 2, an inner bush 3, a support 4, a bracket 5, a squirrel cage spring 6 and Counterweight 7. Wherein: the inner bushing is set on the inner bushing installation flange 53 at the end of the cantilever end of the bracket 5; the outer bushing is installed on the squirrel cage elastic connecting flange 51 of the bracket 5 through the squirrel cage elastic 6 On; the distance between the inner peripheral surface of the outer bushing 2 and the outer peripheral surface of the inner bushing 3 forms an annular chamber for installing the elastic ring 1; the radial distance of the annular chamber is the same as that of the elastic ring 1 to match the thickness; bracket 5 is installed on the support 4. A first vibrator 8 and a second vibrator 9 as vibration excitation sources are installed on the outer circumference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com