Continuous variable valve mechanism driven by linear motor

A linear motor and valve mechanism technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve problems such as difficulty in adapting to the working condition range of internal combustion engines, inability to realize continuous change of valve lift, etc., to achieve simple mechanism, maintain power and The effect of thermal efficiency and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

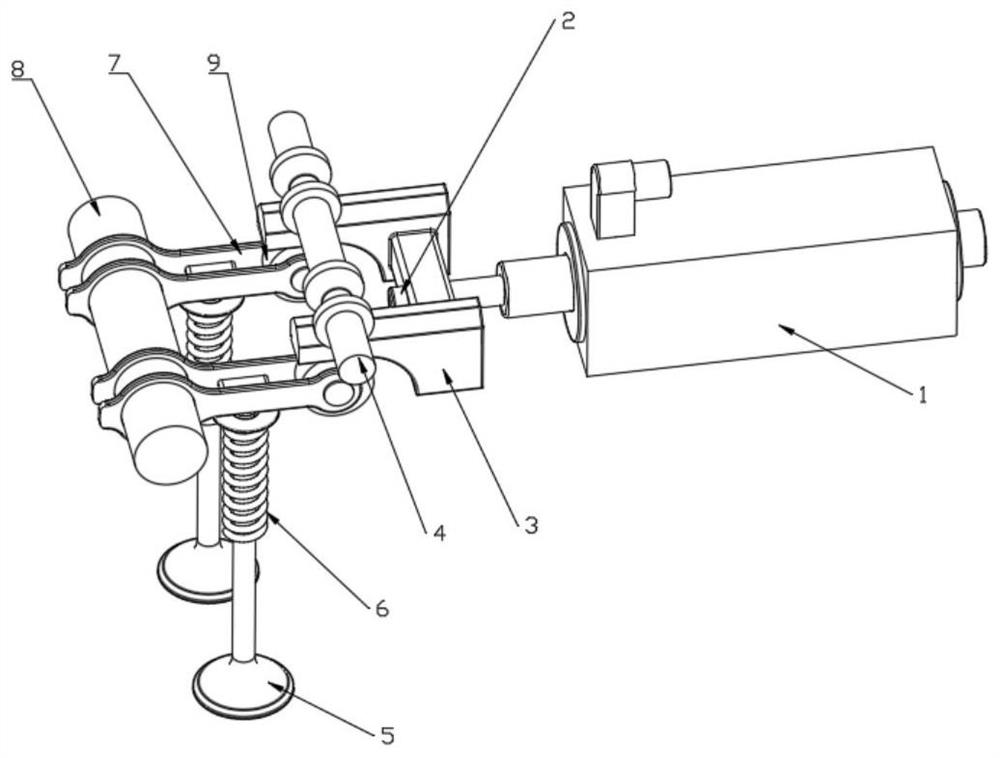

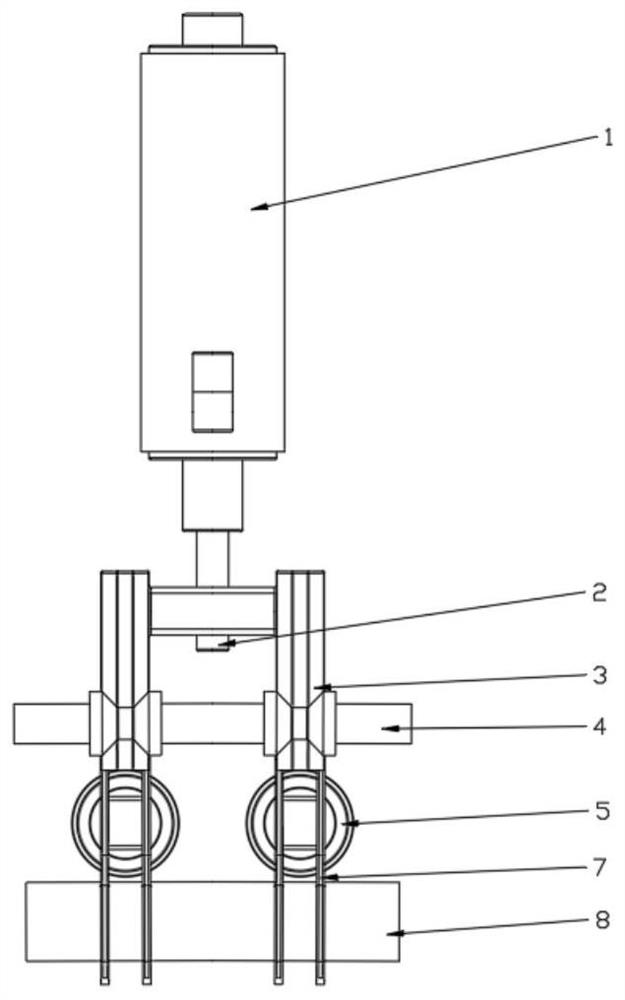

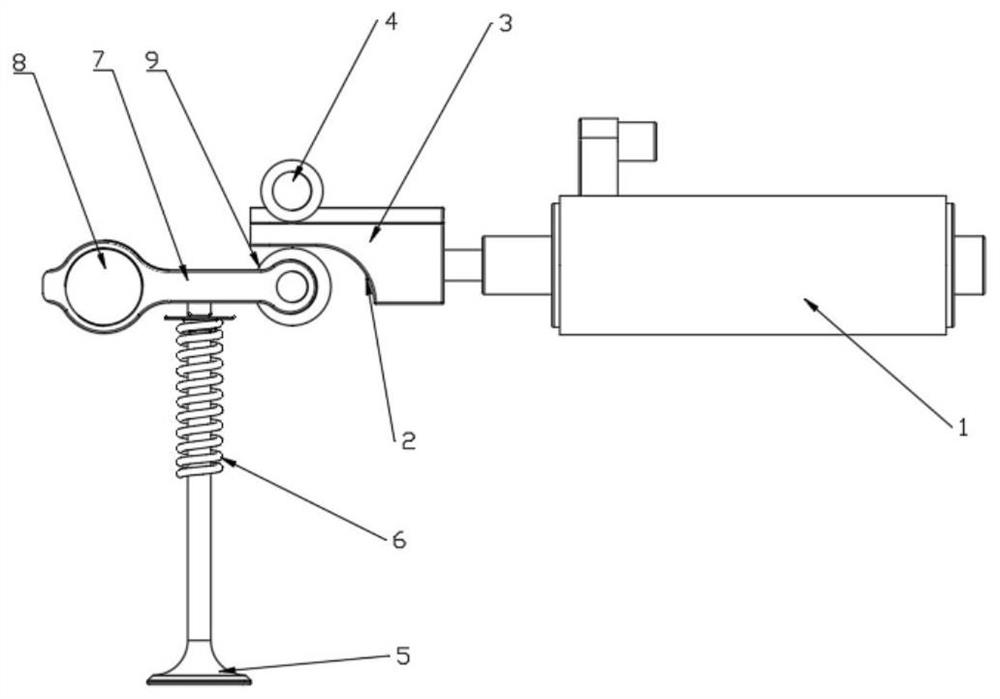

[0016] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0017] Such as Figure 1 to Figure 6 Shown, the present invention consists of linear motor (1), bolt (2), slide block (3), positioning shaft (4), rocking arm (5), valve (6), spring (7), rocking arm shaft ( 8), roller (9) form.

[0018] In the present invention, unless otherwise stated, the engine refers to a four-stroke reciprocating piston internal combustion engine.

[0019] As shown in the figure, the central hole of the slider (3) is divided into two stages of stepped holes, which are respectively the first stepped hole and the second stepped hole from front to back, and the diameter of the second stepped hole is larger than that of the first stepped hole. The shape of the two-step hole can be matched with the shaft end of the linear motor (1) through its mating surface to determine the relative position of the motor and the slider, to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com