Ultrahigh-strength broken bullet protective layer

A protective layer, ultra-high-strength technology, applied in protective buildings/shelters, building types, buildings, etc., can solve problems such as difficult large-scale pouring, constraints on engineering design and construction, and unsuitable for on-site use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

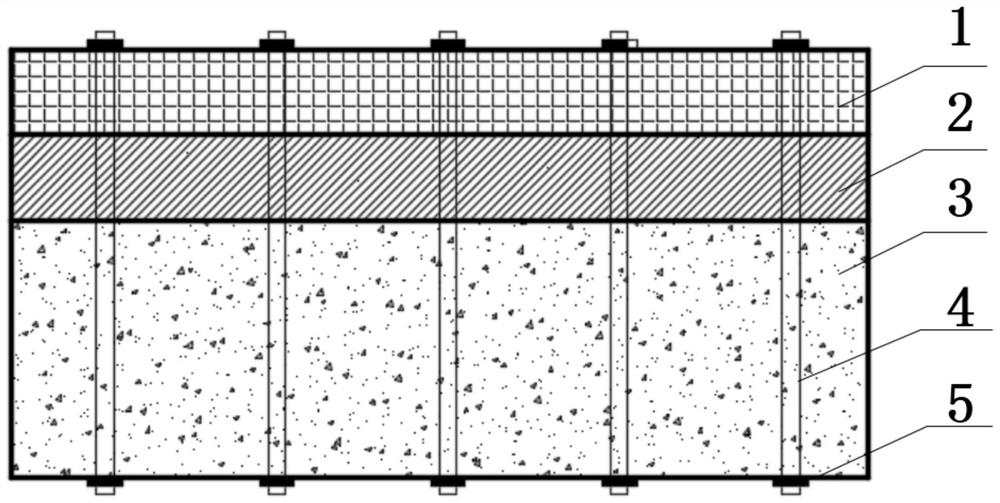

[0036] combine figure 1 As shown, the present invention is further described: a structure of an ultra-high-strength fragmentation shield.

[0037] An ultra-high-strength fragmentation protection layer, the ultra-high-strength fragmentation protection layer is in order from top to bottom: ultra-high-strength steel layer 1, ordinary steel layer 2 and concrete layer 3, and connected by ultra-high-strength bolts and nuts to form an overall composite structure . Among them, the tensile strength of ultra-high-strength steel layer 1 is 1600MPa, the yield strength is 1330MPa, the elongation is 10%, the reduction of area is 45%, and the U-notch impact toughness is 70J / cm 2 , the fracture toughness is 105MPa / m 2 , through prefabricated construction, the length of a single piece is 4m, the width is 4m, and the thickness is 15cm; the tensile strength of ordinary steel layer 2 is 600MPa, the yield strength is 355MPa, the elongation is 16%, and the reduction of area is 40%. Through prefa...

Embodiment 2

[0040] In this example, by giving a test method for evaluating the technical effect of the present invention, the test data obtained by using the test method for the technical solution of the present invention are obtained.

[0041] The test data of the present invention mainly includes physical test data and numerical simulation data.

[0042] Physical test data results: 10cm-thick ultra-high-strength steel can resist 1000kg ground penetrating projectile penetration at 350m / s.

[0043] Numerical simulation test data results: 15cm thick ultra-high-strength steel did not penetrate, but the deformation was large; 10cm ultra-high-strength steel + 100cm concrete was penetrated; 10cm ultra-high-strength steel + 15cm ordinary steel, the projectile was broken. Considering the increase in the speed of striking weapons, it is determined that the thickness of ultra-high-strength steel is 15cm, that of ordinary steel is 15cm, and that the minimum thickness of concrete is 30cm according t...

Embodiment 3

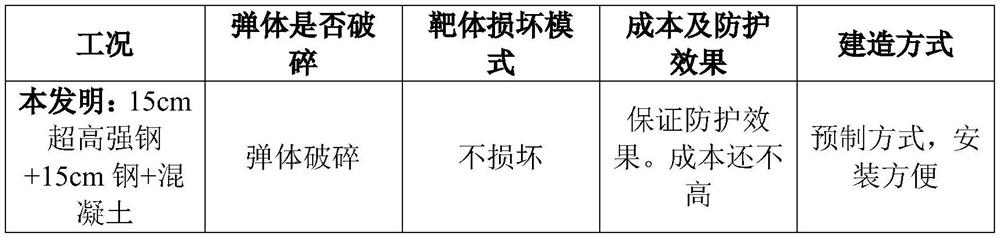

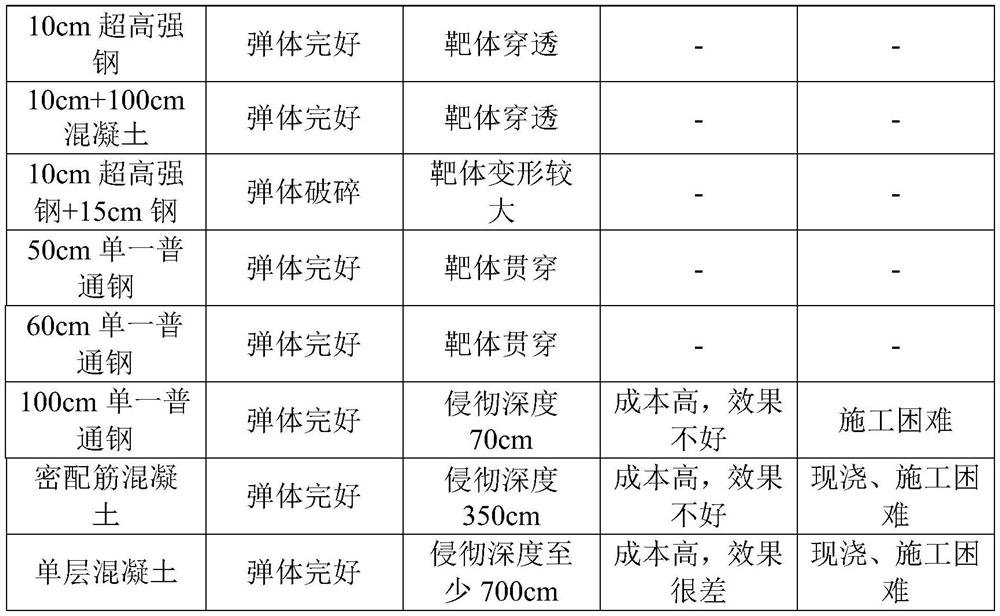

[0045] In this embodiment, the screening test design and corresponding test data are given through comparative tests under different working conditions.

[0046] Table: List of comparative tests under different working conditions

[0047]

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com