Sulfur-containing intumescent flame retardant and preparation method thereof

A technology of intumescent flame retardant and compound, which is applied in the field of polymer additives and its preparation to achieve good flame retardant effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the intumescent flame retardant provided by the present embodiment comprises the following steps:

[0028] (1) 5 parts of carboxymethyl cellulose are dissolved in 1000 parts of water to obtain carboxymethyl cellulose solution;

[0029] (2) Dissolving 1 mol of sodium p-aminobenzenesulfonate and 1 mol of melamine in 2 mol of 37% formaldehyde aqueous solution at 50° C. for 1 hour under magnetic stirring to obtain an intermediate product;

[0030] (3) The above carboxymethyl cellulose solution and the prepared intermediate product were magnetically stirred at 50° C. for 24 hours to obtain an intumescent flame retardant.

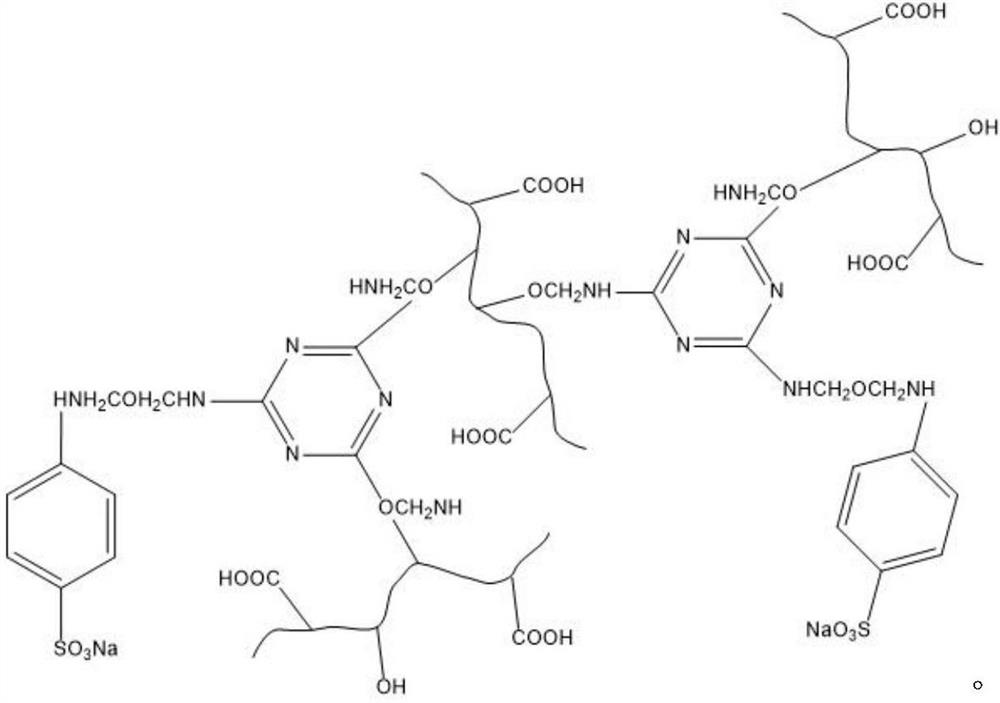

[0031] After testing, the chemical structural formula of the intumescent flame retardant provided in this embodiment is as follows:

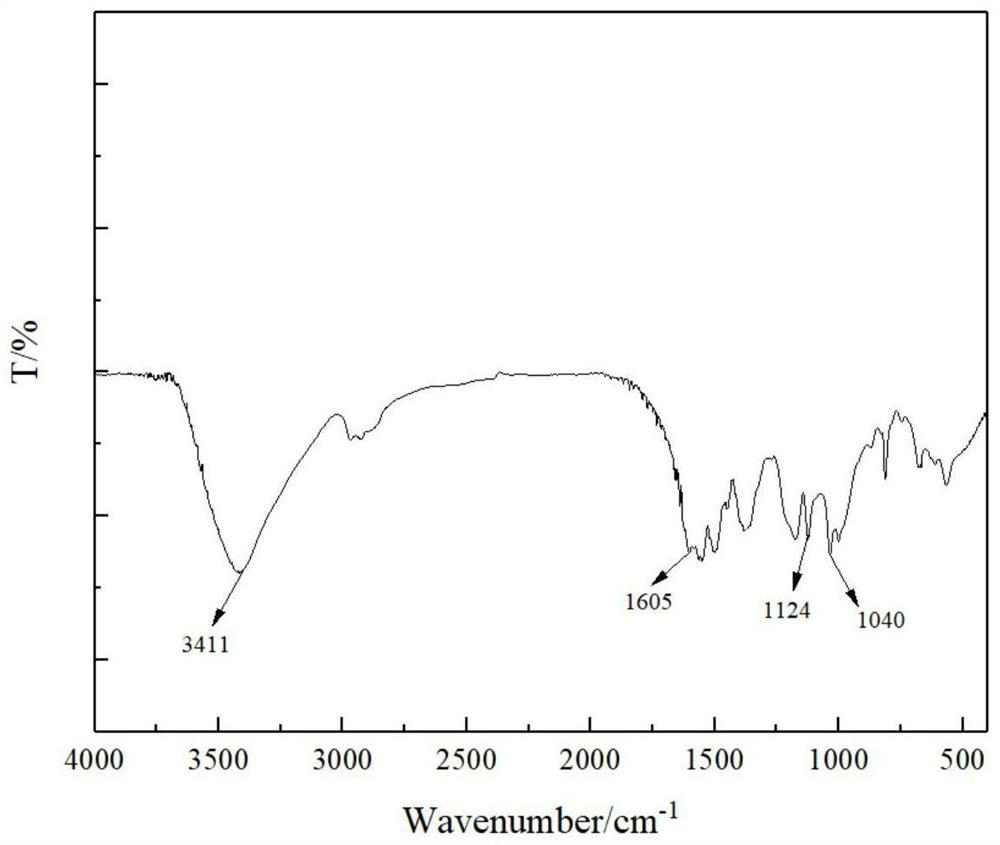

[0032] figure 1 The infrared spectrogram of the intumescent flame retardant provided in this example.

[0033] As shown in the figure, at wave number 3000-3500cm -1 The peak fluctuation in the r...

Embodiment 2

[0037] At 50°C, mix the intumescent flame retardant and water-based polyurethane according to the ratio in Table 1 below, mix well with mechanical stirring, and then introduce the solution into a custom-made polytetrafluoroethylene mold to prepare a standard sample . According to the GB / T2408-2008 standard, the vertical combustion of the flame-retardant water-based polyurethane sample was measured.

[0038]

[0039] Table 1 Compounding scheme of WPU

[0040] sample Waterborne polyurethane / % Flame retardant / % WPU 100 0 WPU1 98 2% WPU2 97 3% WPU3 96 4%

[0041] The measured results are shown in Table 2 below. The flame retardant grade of waterborne polyurethane without adding flame retardant is only HB grade, and there are molten drops; when the flame retardant is added at 3%, the flame retardant grade reaches V-1, Melt droplets did not appear. And as the flame retardant content increases, the flame retardant effect is better. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com