CO2 zero-emission production process and system for calcining limestone by using solar energy

A technology for calcining limestone and production process, applied in the field of CO2 zero emission production process and system, can solve the problems of slow development, low concentration and high cost in the field of carbon emission reduction, to overcome the problems of volatility and intermittent, to achieve zero CO2 Emissions, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

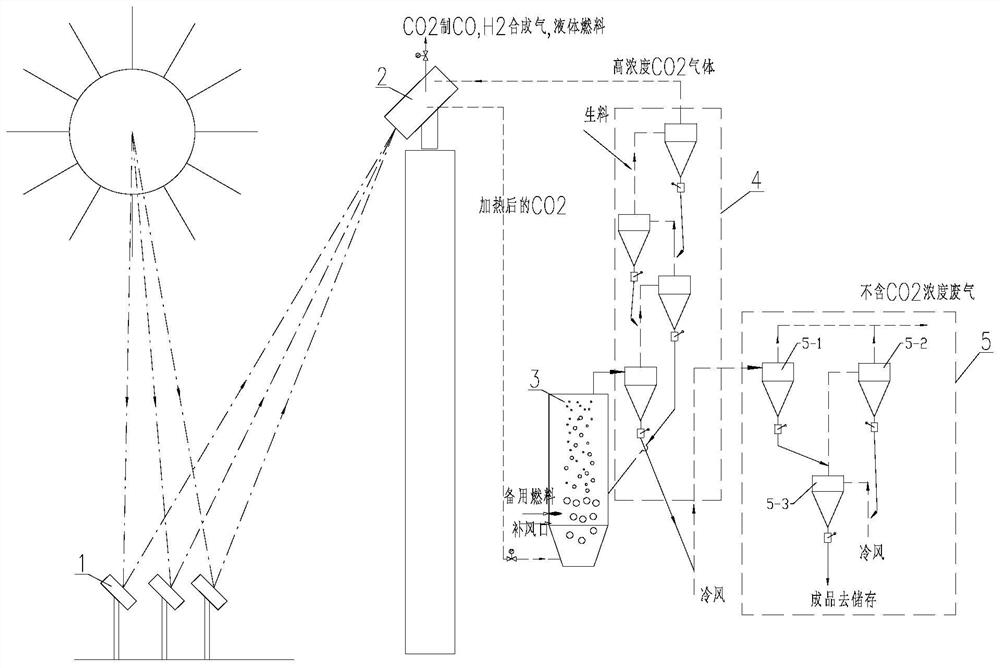

[0033] see figure 1 , this embodiment provides a CO using solar energy to calcinate limestone 2 The zero-emission production system includes a preheater system 4, a calciner 3, a mirror field 1, a thermal energy storage device 2 and a cyclone cooler 5, and the bottom of the penultimate preheater of the preheater system 4 is discharged The mouth is connected with the raw material inlet of the calciner 3, the outlet at the top of the calciner 3 is connected with the inlet of the final preheater of the preheater system 4, and the outlet at the bottom of the final preheater of the preheater system 4 is connected with the The inlet of the cyclone cooler 5 is connected, and the cyclone cooler 5 includes at least one cyclone cylinder; the exhaust gas outlet of the preheater system 4 is connected with the heat collector 2, and the heat collector 2 absorbs the The energy of the mirror field 1, the high concentration CO of the thermal storage 2 2The flue gas output port is connected w...

example 1

[0039] When the solar energy is sufficient, a CO2 that uses solar energy to calcine limestone 2 Zero-emission production process, the steps are as follows:

[0040] (1) Using artificial intelligence technology to make the mirror field 1 automatically track sunlight;

[0041] (2) The solar energy is reflected by the mirror field 1 to the thermal energy storage device 2, and the thermal energy storage device 2 can focus and store energy;

[0042] (3) The concentrated solar energy will collect high-concentration CO 2 The exhaust gas at the kiln tail of the gas is heated and transported to the calciner 3 to provide heat for calcining and decomposing limestone;

[0043] (4) Decomposed high concentration CO 2 The exhaust gas passes through the preheater system 4 to preheat the limestone and returns to the heat collector 2;

[0044] (5) A part of the heat collector 2 with high concentration CO 2 The gas is heated and circulated to the calciner 3 to provide heat, and a part of th...

example 2

[0047] When solar energy storage is insufficient, a CO2 that uses solar energy to calcine limestone 2 Zero-emission production process, the steps are as follows:

[0048] (1) Using artificial intelligence technology to make the mirror field 1 automatically track sunlight;

[0049] (2) The solar energy is reflected by the mirror field 1 to the thermal energy storage device 2, and the thermal energy storage device 2 can focus and store energy;

[0050] (3) The concentrated solar energy will collect high-concentration CO 2 The exhaust gas at the kiln tail of the gas is heated and transported to the calciner 3 to provide heat for calcining and decomposing limestone;

[0051] (4) High concentration of CO decomposed from limestone 2 The exhaust gas passes through the preheater system 4 to preheat the limestone and returns to the heat collector 2;

[0052] (5) A part of the heat collector 2 with high concentration CO 2 The gas is heated and circulated to the calciner 3 to provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com