Eccentric ball bearing outer ring forming method for controlling distribution of metal flow lines along channels

A bearing outer ring and metal streamline technology, applied in metal processing equipment, mechanical equipment, engine components, etc., can solve the problem of reducing the contact fatigue performance of the raceway surface of the ring, and achieve grain and primary carbide refinement, Effect of increasing strain and improving contact fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

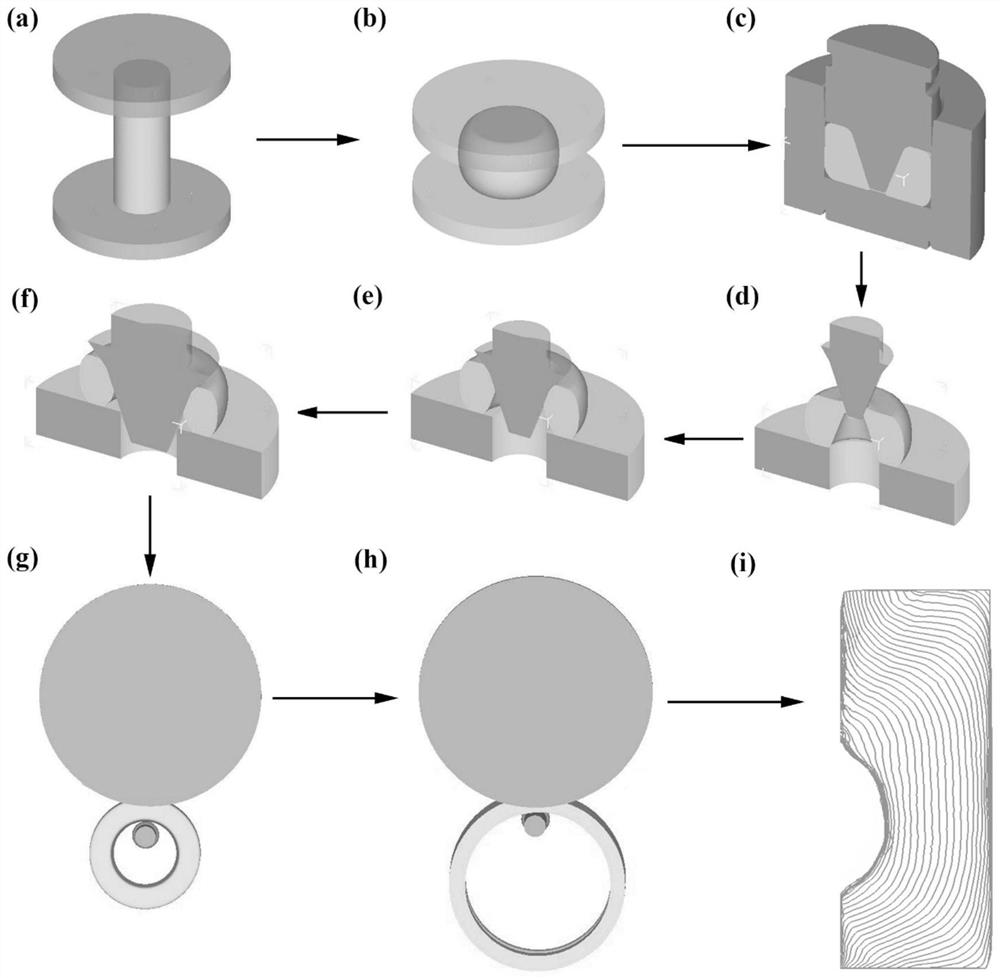

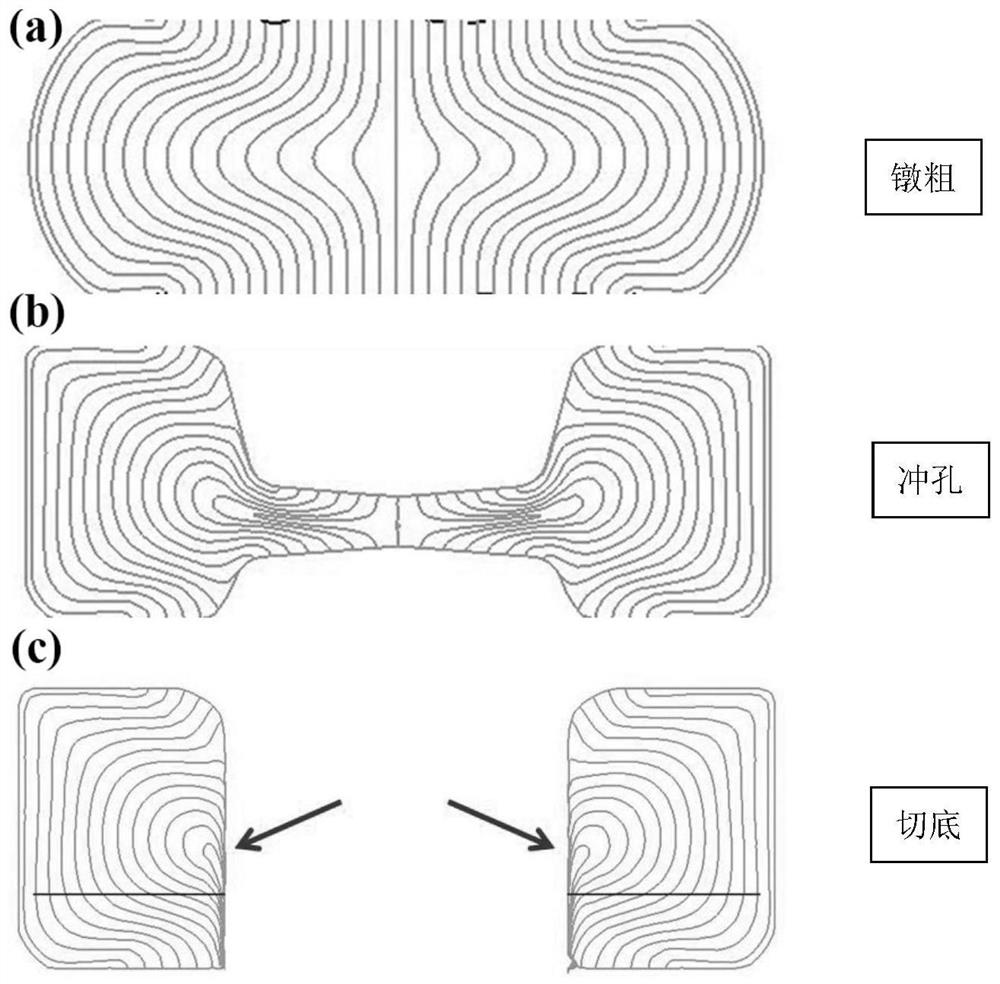

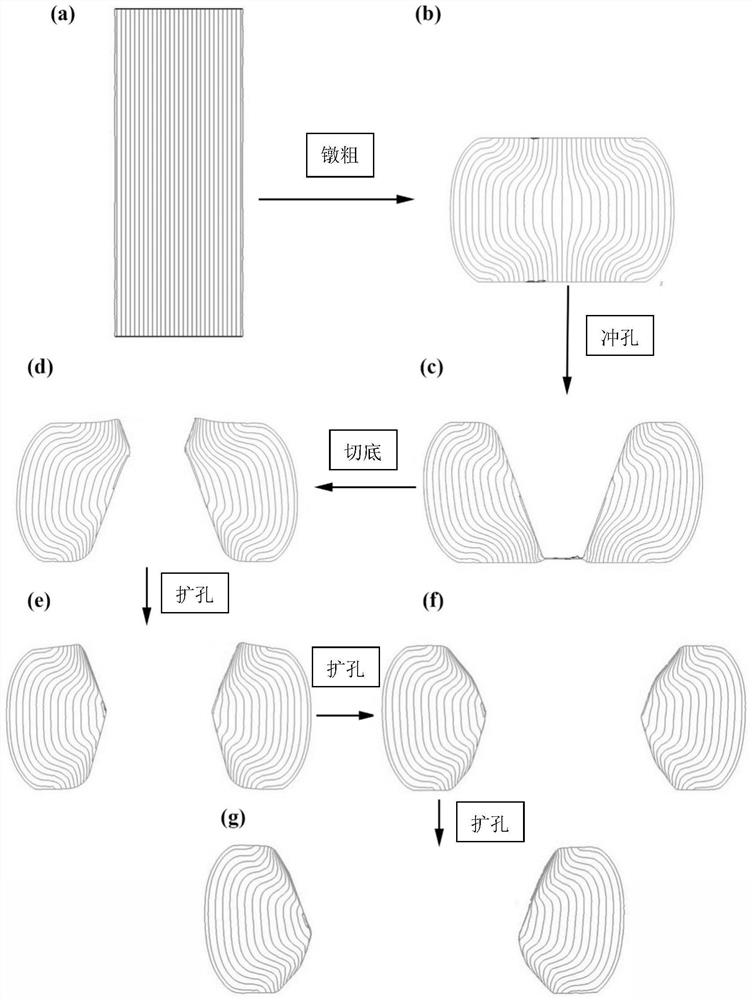

[0020] Specific Embodiment 1: This embodiment is a method for forming the outer ring of an eccentric ball bearing that controls the distribution of metal streamlines along the channel, such as figure 1 As shown, the method flow is: upsetting, punching-rolling forming metal flow line distribution along the channel of the eccentric bearing outer ring-ash buried cooling-spheroidizing annealing treatment, turning, grinding and superfinishing, the specific process is as follows :

[0021] 1. Heat the bar material with an aspect ratio of 1.6 to 2.5 at 1000°C to 1150°C for 0.9h to 1.2h, and then perform an upsetting process with an upset ratio of 1.8 to 2.8;

[0022] The formation of metal flow lines is closely related to the whole process of upsetting, punching and rolling, and it is gradually formed in each process and has heredity. Therefore, it is necessary to control the metal flow line during the forging process to make it reasonably distributed. The metal streamline directio...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the bar with an aspect ratio of 1.75 is kept at 1000° C. to 1150° C. for 0.9 h to 1.2 h. Others are the same as the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment is different from Embodiment 2 in that: in step 1, the rod material with an aspect ratio of 1.75 is kept at 1075°C for 0.9h-1.2h. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com