Ferrite composite material laser cutting method

A composite material and laser cutting technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as edge damage, achieve the effect of preventing brittle damage and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

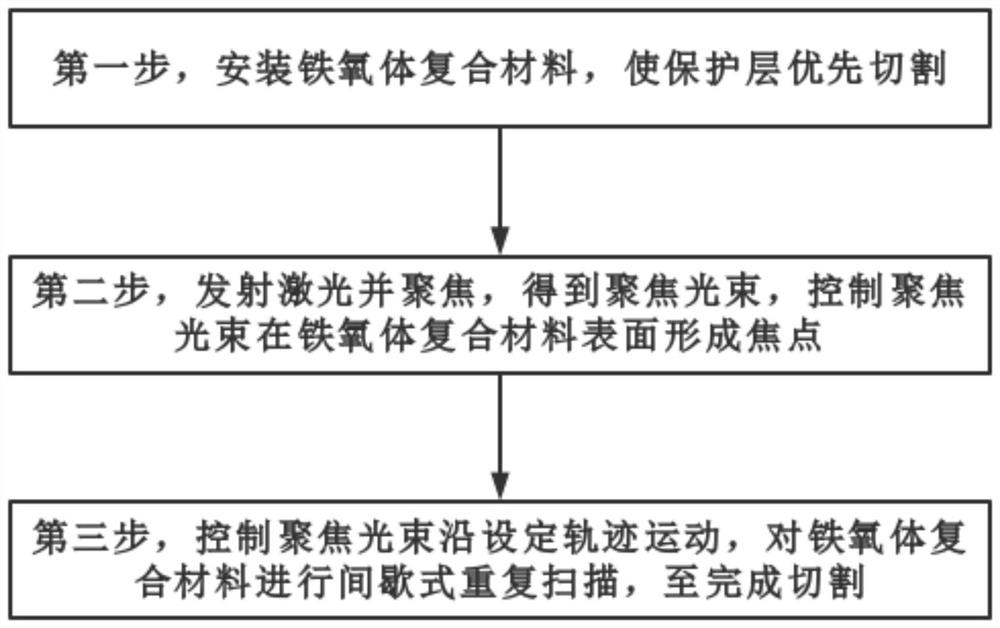

[0038] A kind of laser cutting method of ferrite composite material, such as figure 1 shown, including the following steps:

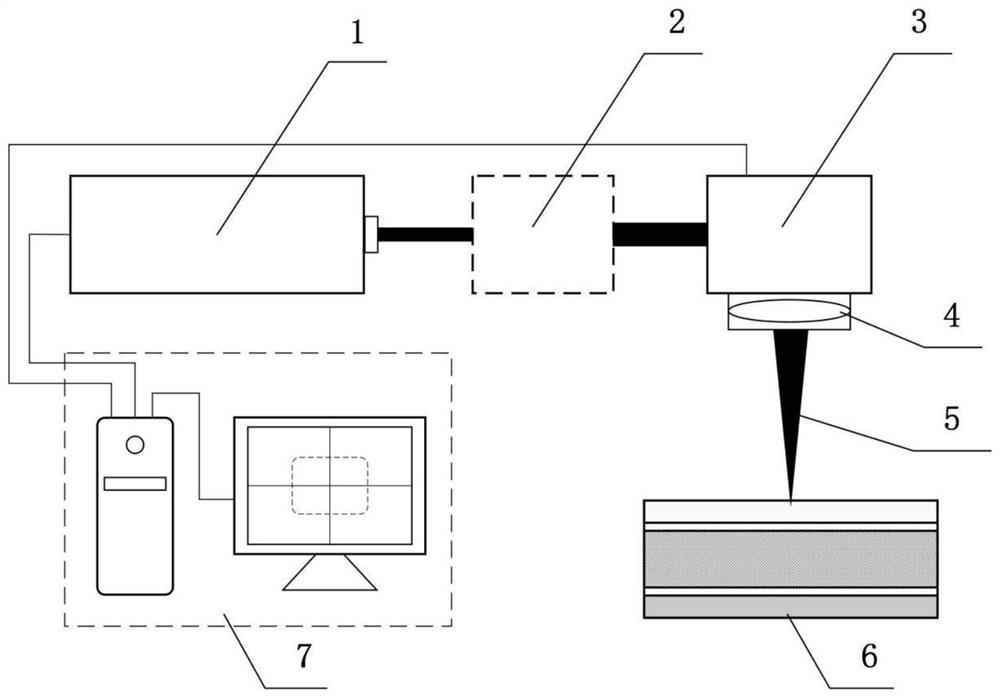

[0039] In the cutting device preparation stage, prepare the following devices, including:

[0040] Engineering machine 7, on which laser software and cutting software are installed;

[0041] Nanosecond ultraviolet laser 1, which is controlled by laser software, provides laser light as a laser source, and its parameters are pulse width less than 15ns, wavelength 355nm, power 5-20W, and repetition frequency up to 200kHz.

[0042] The optical component 2 can be used to adjust the laser light emitted by the nanosecond ultraviolet laser 1 .

[0043] The telecentric field lens 4 can focus the laser light to form a focused beam 5 .

[0044] The digital vibrating mirror 3 is controlled by the cutting software, and is used to control the movement of the focal point of the focused beam 5 and scan the ferrite composite material 6 .

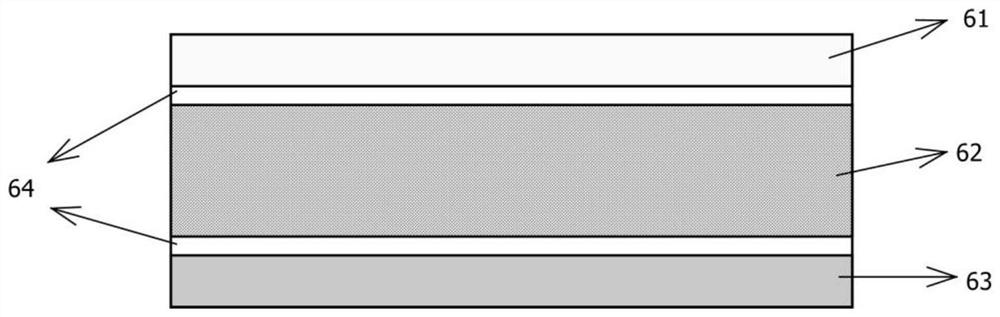

[0045] The device configur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com