Technology for diagnosing material leakage of filter cloth by monitoring underflow filtrate on line and underflow type filter mechanism

A filtration mechanism and undercurrent technology, applied in filtration and separation, suspension and porous material analysis, measurement devices, etc., can solve problems such as affecting filtration efficiency and effect, affecting filtrate product quality, blocking filtrate network, etc., so as to avoid clogging of filtrate. Network, convenient emergency shutdown disposal, no blocking effect of filtrate network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

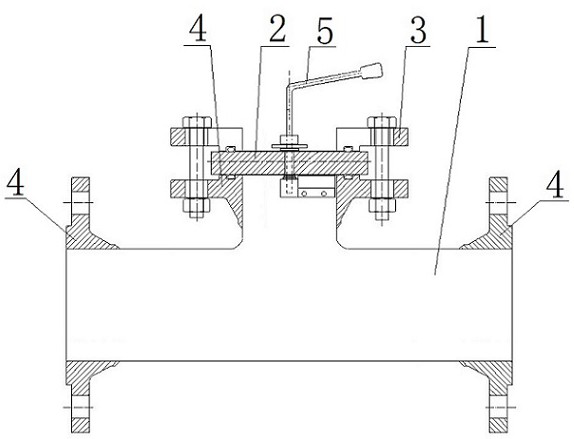

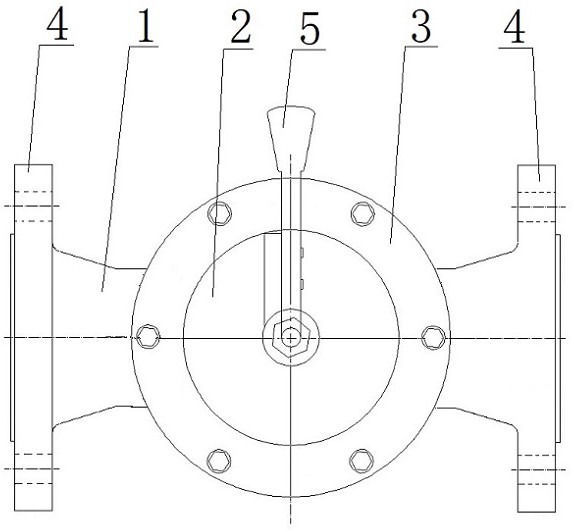

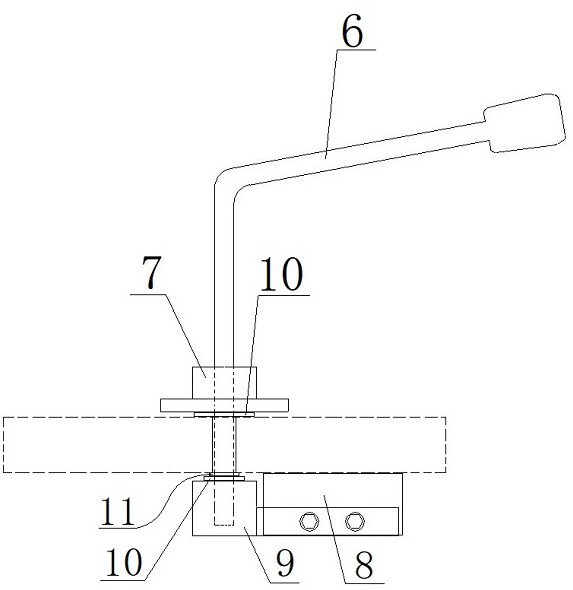

[0021] An online monitoring of undercurrent filtrate to diagnose filter cloth leakage technology 14 (hereinafter referred to as: monitoring undercurrent filtrate device). Diagnosis of filter cloth leakage technology 14, that is, a device for indirect monitoring of undercurrent filtrate online to judge filter cloth damage and leakage (similar to checking urine to diagnose disease), including drainage tee pipe 1, liquid inspection mirror 2, and pressure mirror flange 3 , three-way flange 4, mirror scraping device 5; the whole is installed between the thrust plate undercurrent pipe 17 and the external drain pipe 15, the discharged filtrate can be observed through the sight glass online, when the filtrate is abnormally turbid ( That is, when the filtrate is much turbid than normal), it means that the filter cloth is damaged and leaking material, so as to stop the machine in time for disposal (replace the filter cloth), effectively avoid continuous leakage of material from clogging ...

Embodiment 2

[0030] An undercurrent filter mechanism 18 (abbreviation: filter mechanism), that is, multi-filter chambers 22 connected in series to feed undercurrent effluent filter mechanism 18, using the online monitoring underflow filtrate provided by the present invention to diagnose filter cloth leakage technology 14 (abbreviation: monitoring undercurrent filtrate device), the filter mechanism 18 is mainly composed of end-to-end sealed anti-corrosion filter plate, undercurrent filter plate 20, filter cloth 21, cloth clamping distributor, filter plate sliding support, sealing ring at the end of each fluid inlet and outlet hole, monitoring undercurrent filtrate Device 14, each fluid inlet and outlet is composed of external pipelines; it can filter various odorous suspension materials (that is, a mixture of liquid and solid particles), multi-filter chambers 22 are connected in series to feed dark outflow liquid, and online monitoring filter cloth 21 is damaged and leaked function. The tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com