Wide-temperature type sodium ion battery electrolyte

A sodium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as fire, decrease in conductivity, increase in charge transfer resistance, etc., achieve low viscosity, high boiling point and flash point, The effect of improving the capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

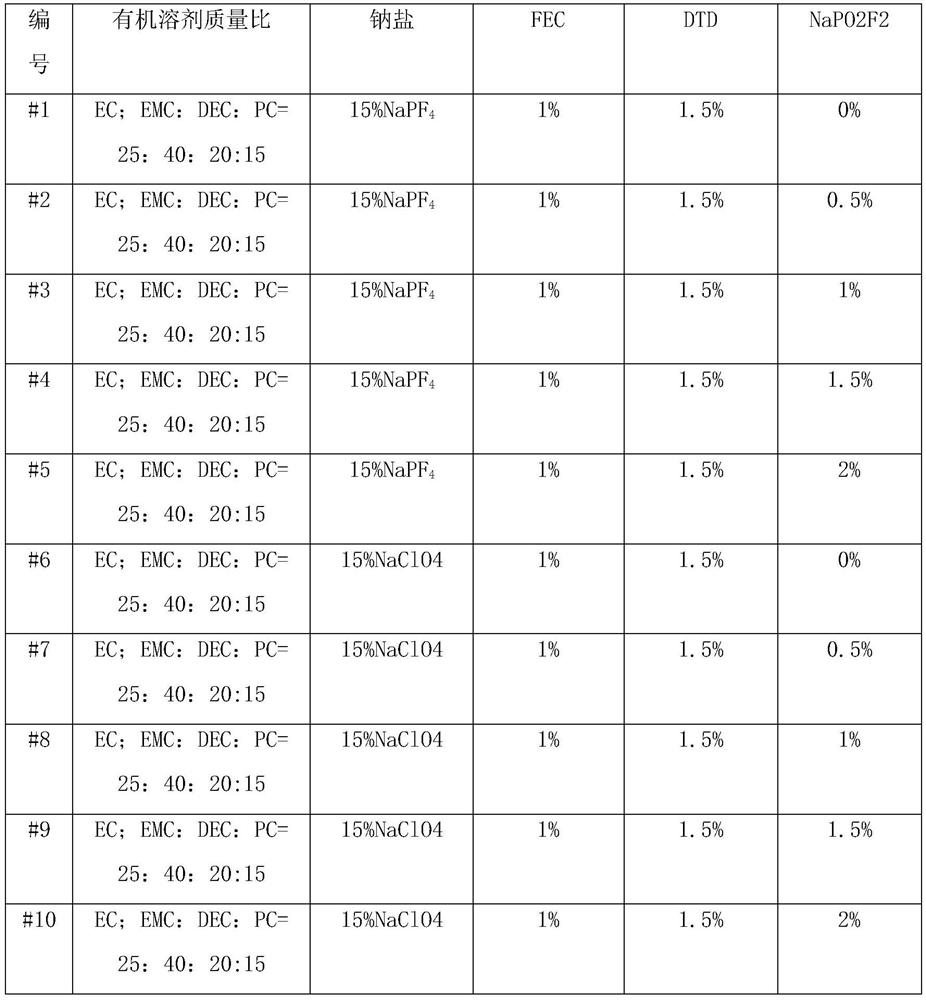

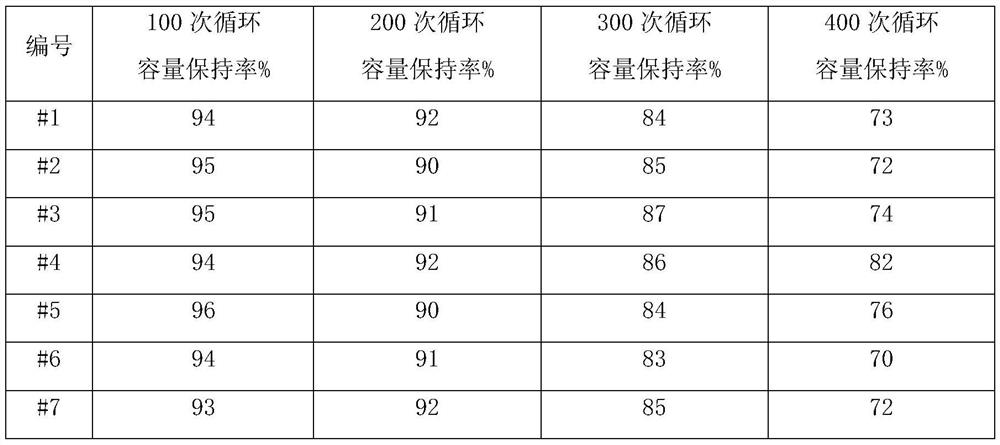

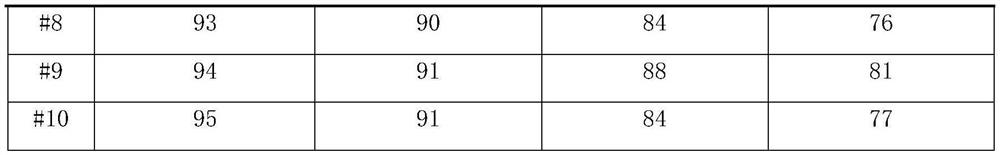

[0024] Embodiment 1: a kind of wide temperature type sodium-ion battery electrolyte, comprises organic solvent, sodium salt and functional additive; It is characterized in that: comprise three (trimethylsilyl) phosphate, N, N- One or more of dimethyltrifluoroacetamide, fluoroethylene carbonate, vinyl sulfate, and sodium difluorophosphate;

[0025] Described three (trimethylsilyl) phosphoric acid esters are high-temperature cycle performance additives; Described N, N-dimethyltrifluoroacetamide is low-temperature cycle performance additives;

[0026] Described organic solvent comprises one or more in ethylene carbonate, ethyl methyl carbonate, diethyl carbonate and propylene carbonate;

[0027] The sodium salt is one or both of sodium hexafluorophosphate or sodium perchlorate;

[0028] According to parts by weight, the functional additive includes 0.5-1.5 parts of fluoroethylene carbonate, 1-2 parts of vinyl sulfate and 0.5-2 parts of sodium difluorophosphate;

[0029] Accordi...

Embodiment 2

[0034] Example 2: An electrolyte solution for a wide-temperature sodium-ion battery; prepared by the following method, at room temperature, in a glove box, mixing organic solvents in proportion, dissolving sodium salt in the mixed organic solvent, and then adding functional additives ;

[0035] Wherein, the functional additive includes 0.5-1.5 parts of fluoroethylene carbonate, 1-2 parts of vinyl sulfate, 0.5-2 parts of sodium difluorophosphate; the organic solvent includes 20-30 parts of carbonic acid vinyl ester, 35-45 parts of ethyl methyl carbonate, 15-25 parts of diethyl carbonate and 10-20 parts of propylene carbonate; the sodium salt is 10-20 parts of sodium hexafluorophosphate or perchloric acid sodium.

Embodiment 3

[0036] Example 3: An electrolyte solution for a wide-temperature sodium-ion battery; prepared as follows, at room temperature, in a glove box, mixing organic solvents in proportion, dissolving sodium salt in the mixed organic solvent, and then adding functional additives ;Activate the battery by charging and discharging with 1 / 10C 2.5V to 3.6V at a constant temperature of 25°C at room temperature;

[0037] Wherein said functional additive includes 0.5 parts of fluoroethylene carbonate, 1 part of vinyl sulfate and 0.5 part of sodium difluorophosphate; said organic solvent includes 20 parts of ethylene carbonate, 35 parts of methyl ethyl carbonate Esters, 15 parts of diethyl carbonate and 10 parts of propylene carbonate; the sodium salt is 10 parts of sodium hexafluorophosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com