Safety type self-temperature-limiting electric tracing band and preparation method thereof

An electric heating cable and self-limiting temperature technology, which is applied to the shape of heating elements, other household appliances, household components, etc., can solve the problems of poor flame retardancy and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A safe self-limiting temperature electric heating cable is composed of nano conductive carbon black and two parallel busbars plus an insulating layer. The insulating layer is made by the following steps:

[0043] Dissolve modified polystyrene in N,N-dimethylformamide, stir at a speed of 150r / min and a temperature of 20°C, add a synergistic cross-linking agent, mix well, and add it to the mold , to be cured to obtain an insulating layer.

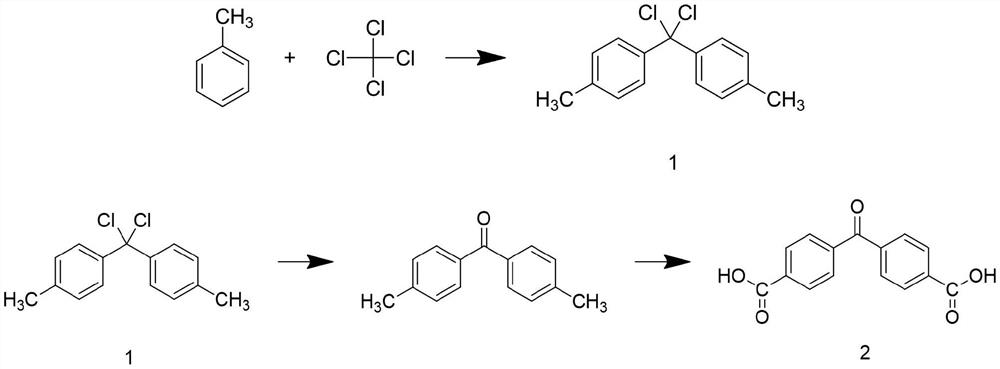

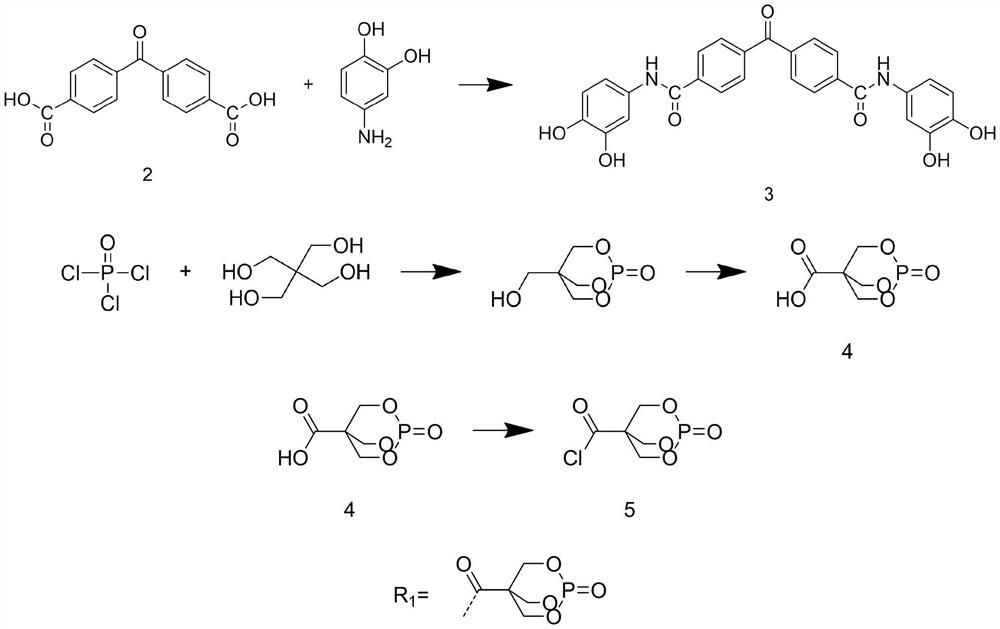

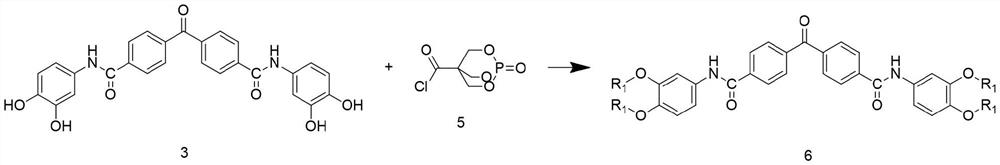

[0044] Modified polypropylene is made by the following steps:

[0045] Step A1: Mix aluminum trichloride and carbon tetrachloride evenly, stir at 200r / min and 10°C, add toluene, and react for 1 hour at 40°C to prepare To obtain intermediate 1, mix intermediate 1 and deionized water uniformly, under the condition of a temperature of 110°C, reflux for 1 hour, filter and remove the filtrate, and mix the filter cake, carbon tetrachloride, and potassium permanganate uniformly, Under the condition of rotation speed of 150r / min and temperatur...

Embodiment 2

[0053] A safe self-limiting temperature electric heating cable is composed of nano conductive carbon black and two parallel busbars plus an insulating layer. The insulating layer is made by the following steps:

[0054] Dissolve modified polystyrene in N,N-dimethylformamide, stir at a speed of 180r / min and a temperature of 25°C, add a synergistic cross-linking agent, mix well, and add it to the mold , to be cured to obtain an insulating layer.

[0055] Modified polypropylene is made by the following steps:

[0056] Step A1: Mix aluminum trichloride and carbon tetrachloride evenly, stir at 200r / min and 13°C, add toluene, and react for 1.3h at 45°C. Prepare intermediate 1, mix intermediate 1 and deionized water evenly, under the condition of 115°C, reflux for 1.3h, filter and remove the filtrate, and mix the filter cake, carbon tetrachloride, and potassium permanganate Evenly, under the conditions of rotating speed of 180r / min and temperature of 105°C, reflux reaction was carr...

Embodiment 3

[0064] A safe self-limiting temperature electric heating cable is composed of nano conductive carbon black and two parallel busbars plus an insulating layer. The insulating layer is made by the following steps:

[0065] Dissolve modified polystyrene in N,N-dimethylformamide, stir at a speed of 200r / min and a temperature of 30°C, add a synergistic cross-linking agent, mix well, and add it to the mold , to be cured to obtain an insulating layer.

[0066] Modified polypropylene is made by the following steps:

[0067] Step A1: Mix aluminum trichloride and carbon tetrachloride evenly, stir at 300r / min, and add toluene at a temperature of 15°C, and react for 1.5h at a temperature of 50°C. Prepare intermediate 1, mix intermediate 1 and deionized water evenly, under the condition of 120°C, reflux for 1.5h, filter and remove the filtrate, and mix the filter cake, carbon tetrachloride, and potassium permanganate Evenly, under the condition of rotating speed of 200r / min and temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com