One-step zinc smelting method of molten pool spraying zinc concentrate

A technology of zinc concentrate and molten pool, which is applied in the field of one-step zinc smelting by spraying zinc concentrate in the molten pool, can solve the problems of complex process, high energy consumption, long technical process, etc., and achieve the effect of increasing the operating temperature and efficient and thorough volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Zinc sulfide concentrate (containing Zn: 50.1% by mass) and flux (FeO, SiO 2 and CaO) are mixed and dried, and the mixed material contains 3% (mass) water after drying. The mixed material and oxygen-containing gas are sprayed directly into the molten pool of the jet smelting area from the side blowing lance installed in the jet smelting area of the jet smelting electrothermal reduction furnace. The smelting temperature in the jet smelting area is 1400°C for oxidative desulfurization of zinc sulfide concentrate Smelting to obtain flue gas and high zinc slag, wherein the oxygen volume concentration in the oxygen-containing gas is 40%, and the mixed material is transported in the spray gun with an oxygen-rich gas with an oxygen volume concentration of 25%. The flue gas produced in the jet smelting zone is cooled by the waste heat boiler, dust is collected by the electrostatic precipitator, and then the flue gas is sent to make acid.

[0040] The high-zinc slag enters th...

Embodiment 2

[0043] The method is the same as that of Example 1, except that the dried mixed material and oxygen-containing gas are directly sprayed into the molten pool of the jet smelting zone by the same side-blown lance provided in the jet smelting zone of the jet smelting electrothermal reduction furnace, and the innermost layer of the lance is The mixed material is sprayed into the channel, the oxygen-containing gas is sprayed into the sub-outer channel of the spray gun, and the outermost channel of the spray gun uses nitrogen and water to cool the gun body.

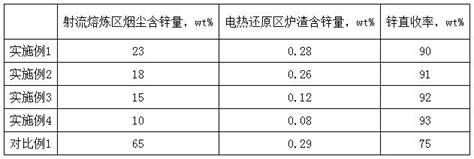

[0044] Table 1 shows the zinc content in the flue dust in the jet smelting zone, the zinc content in the slag in the electrothermal reduction zone, and the zinc direct recovery rate in the method of this embodiment.

Embodiment 3

[0046] The method is the same as in Example 2, except that the zinc sulfide concentrate particle size is 75 μm or less, accounting for 90%, the mixed material contains 1% (mass) of water after drying, and the oxygen volume concentration in the oxygen-containing gas in the jet smelting zone is 70%. The melting temperature in the jet melting zone is 1500°C, and the operating temperature in the electrothermal reduction zone is 1600°C.

[0047] Table 1 shows the zinc content in the flue dust in the jet smelting zone, the zinc content in the slag in the electrothermal reduction zone, and the zinc direct recovery rate in the method of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com