High-efficiency complete-set splicing degumming process for electroplating roller

An electroplating drum and high-efficiency technology, applied in the cleaning method of using tools, electrolytic components, electrolytic process, etc., can solve the problems of unsatisfactory degumming effect, low degumming efficiency, easy to appear residual glue, etc., to achieve convenient degumming Easy to operate, easy to scrape glue, improve the effect of glue removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

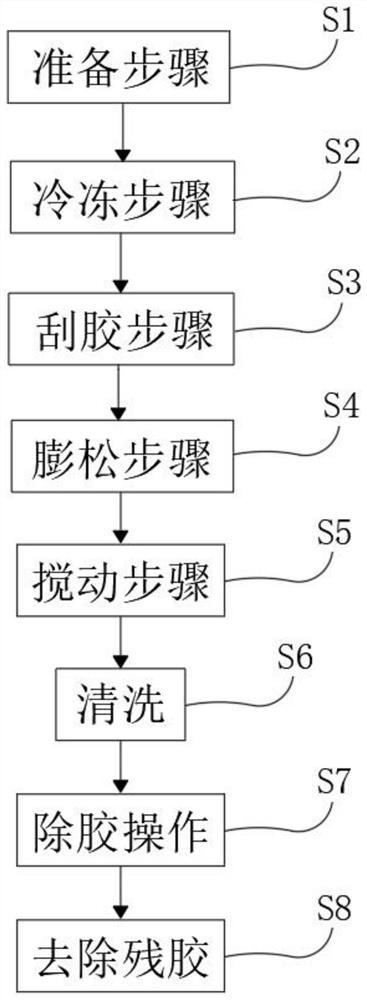

[0032] Embodiment one, refer to figure 1 , a high-efficiency complete splicing degumming process for an electroplating drum, the degumming process includes the following steps:

[0033] S1, the preparation step, first splicing and fixing the rollers that need to be degummed, so as to facilitate batch and high-efficiency complete degumming;

[0034] S2, the freezing step, and then put the roller that needs to be degummed into an industrial refrigerator for freezing. The freezing temperature range is -50 ° C, and the freezing time is 2 hours. At this time, the frozen roller is obtained, which can facilitate subsequent degumming;

[0035] S3, the glue scraping step, and then the staff manually scrapes off the glue on the roller with a knife, and then wipes the glue after the glue is scraped, and then visually checks whether there is glue left on the surface of the roller, and if there is no residue, go to the next step. If there is any residue, wipe it again until there is no gl...

Embodiment 2

[0053] Embodiment two, refer to figure 1 , a high-efficiency complete splicing degumming process for an electroplating drum, the degumming process includes the following steps:

[0054] S1, the preparation step, first splicing and fixing the rollers that need to be degummed, so as to facilitate batch and high-efficiency complete degumming;

[0055] S2, the freezing step, and then put the roller that needs to be degummed into an industrial refrigerator for freezing. The freezing temperature range is -40°C, and the freezing time is 1h. At this time, the frozen roller is obtained, which can facilitate subsequent degumming;

[0056] S3, the glue scraping step, and then the staff manually scrapes off the glue on the roller with a knife, and then wipes the glue after the glue is scraped, and then visually checks whether there is glue left on the surface of the roller, and if there is no residue, go to the next step. If there is any residue, wipe it again until there is no glue on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com