Guiding well drilling device

A steerable drilling and drill bit technology, applied in directional drilling, drilling equipment, automatic control systems for drilling, etc., can solve the problems of poor electrical connection stability, prone to failure, difficult to adapt to the downhole environment, etc. The effect of ensuring structural stability and integrity and reducing downhole engineering risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is introduced below by accompanying drawing.

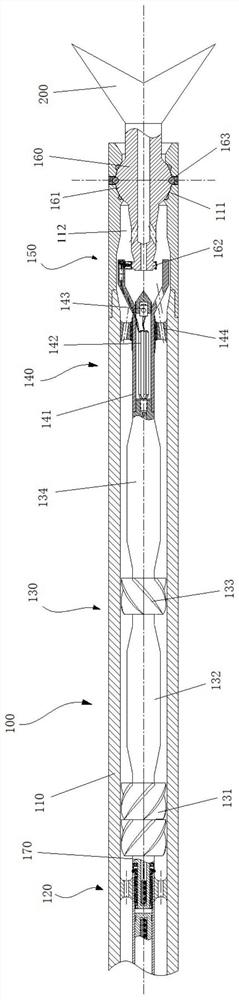

[0026] Such as figure 1As shown, the steerable drilling device 100 includes an outer cylinder 110 and a central shaft 170 sheathed in the outer cylinder 110 . Both the outer cylinder 110 and the central shaft 170 are arranged along the longitudinal axis, and the central shaft 170 is centered relative to the outer cylinder 110 .

[0027] The upper end of the central shaft is rotatably supported on the inner wall of the outer cylinder 110 through the upper end connecting mechanism 120 , and the lower end is rotatably supported on the inner wall of the outer cylinder 110 through the lower end connecting mechanism 140 .

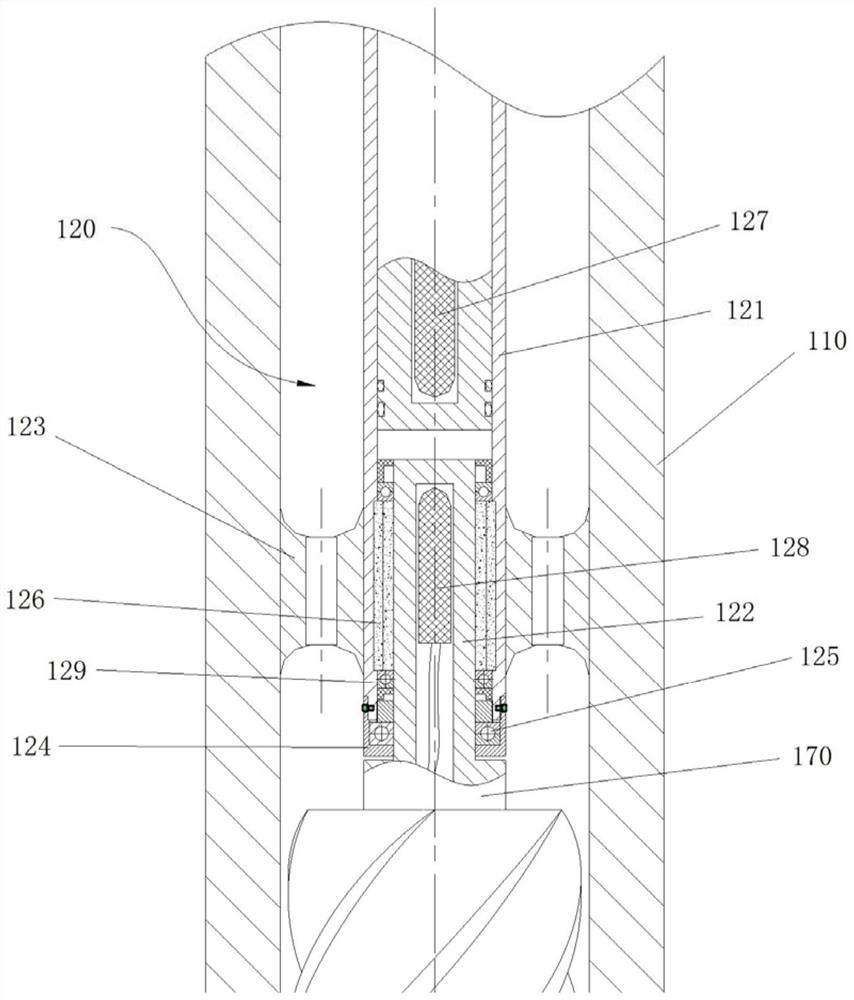

[0028] figure 2 The detailed structure of an embodiment of the upper connection mechanism 120 is schematically shown. The upper connection mechanism 120 includes a first cylinder 121 sleeved in the outer cylinder 110 and extending along the longitudinal axis. The first cylinder 121 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com