Composite particle for improving performance of copper-clad plate

A technology of composite particles and copper-clad laminates, applied in the field of composite materials, can solve the problems of large specific surface area, reduced makeup sustainability, unfavorable heat conduction of polymer matrix, etc., and achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

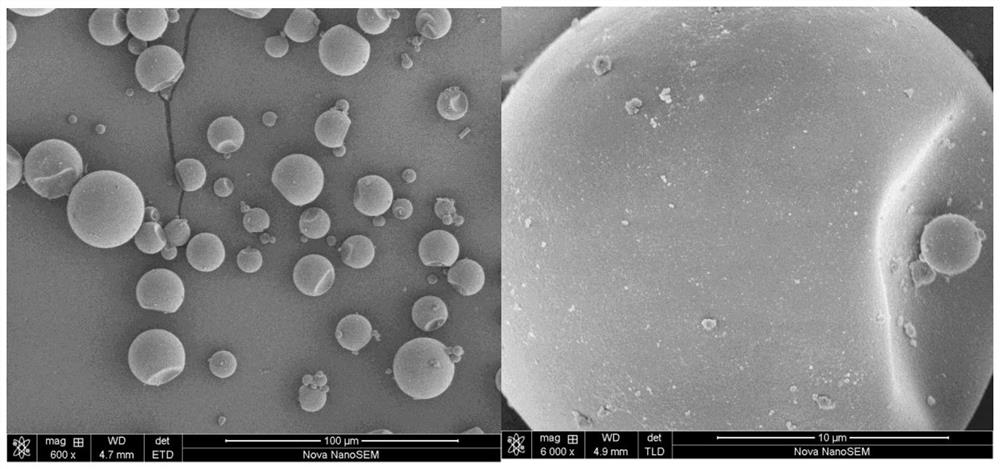

Embodiment 1

[0043] 8.56g of melamine and 20mL of 37% formaldehyde solution were dissolved in 50mL of water, and the reaction was increased to 95 °C for 1.5 hours, during which the pH of the system was maintained with 5% hydrochloric acid and sodium hydroxide solution of 9 to 10. After the reaction is reduced to room temperature to obtain a clear and transparent melamine-formaldehyde resin prepolymer solution. Take MF microspheres 10g, nano alumina 4g, deionized water 86g, put into a three-mouth flask, mechanically stirred for 30min, add 2g melamine - formaldehyde resin prepolymer solution, using 5% HCl to adjust the solution pH, keep the PH between 4 and 5, 85 °C water bath for 5h, filter drying, to obtain a powdered product.

Embodiment 2

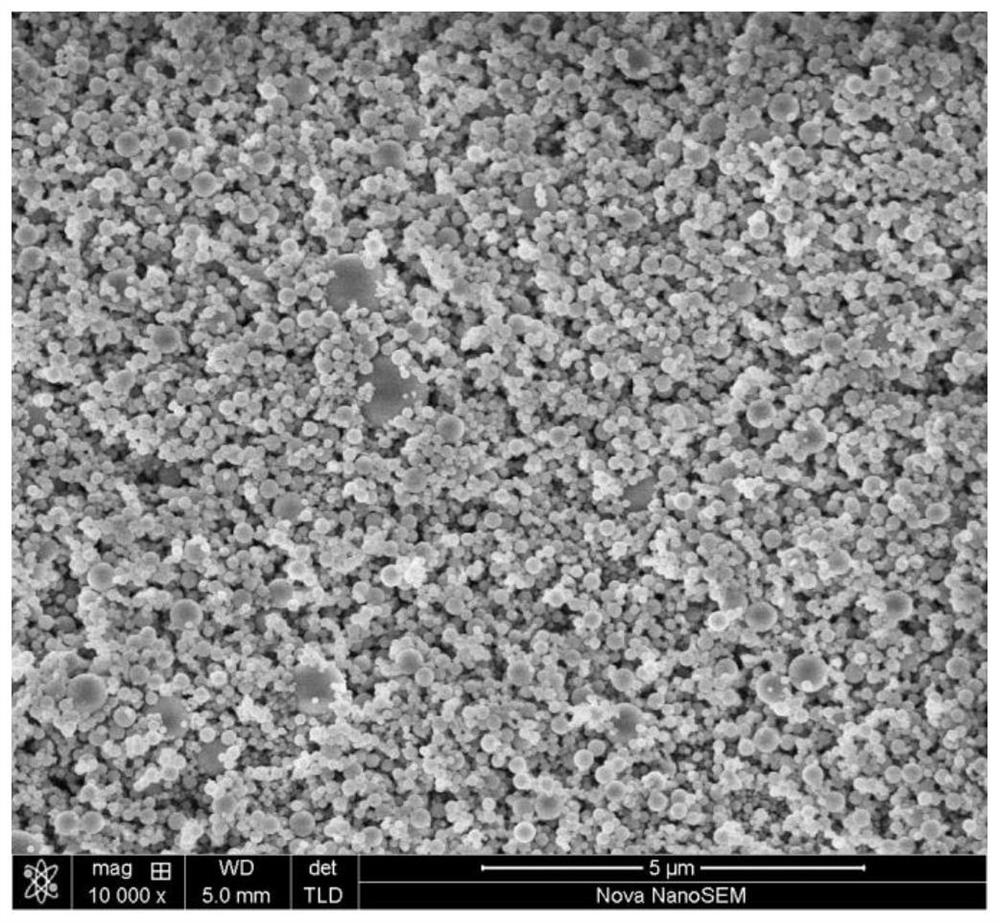

[0045] 8.56g of melamine and 20mL of 37% formaldehyde solution were dissolved in 50mL of water, and the reaction was increased to 60 °C for 2.5 hours, during which the pH of the system was maintained with 5% hydrochloric acid and sodium hydroxide solution of 8~9. After the reaction is reduced to room temperature to obtain a clear and transparent melamine-formaldehyde resin prepolymer solution. Take MF microspheres 10g, nano alumina 6g, deionized water 86g, put into a three-mouth flask, mechanically stirred for 30min, add 1.5g melamine - formaldehyde resin prepolymer solution using 5% HCl adjustment solution PH, keep THE PH between 4 ~ 5, 85 °C water bath for 5h, filter drying, to obtain a powdered product.

Embodiment 3

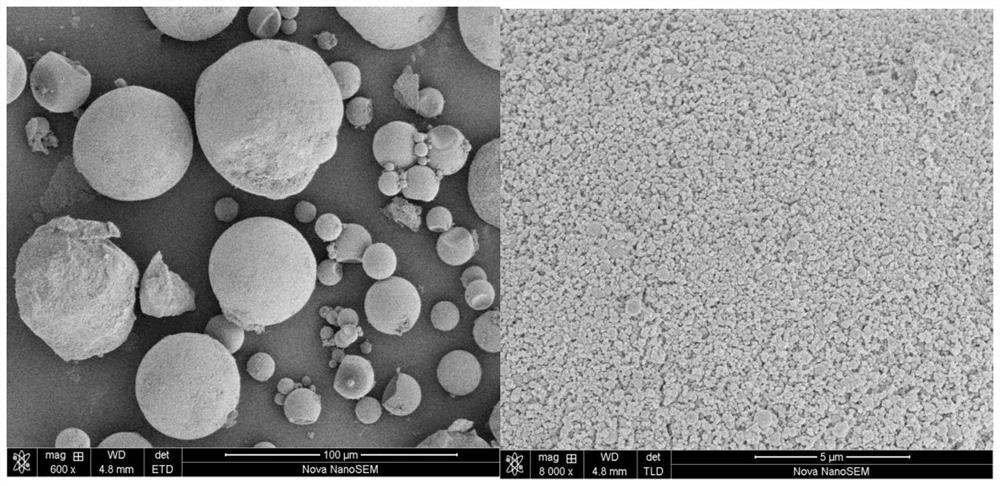

[0047] 8.56g of melamine and 20mL of 37% formaldehyde solution were dissolved in 50mL of water, and the reaction was carried out at 90 °C for 1.5 hours, during which the pH of the system was maintained with 5% hydrochloric acid and sodium hydroxide solution of 8 to 9. After the reaction is reduced to room temperature to obtain a clear and transparent melamine-formaldehyde resin prepolymer solution. Take PS microspheres 10g, nano alumina 4g, deionized water 86g, put into a three-mouth flask, mechanically stirred for 30min, add 2g melamine - formaldehyde resin prepolymer solution using 5% HCl to adjust the solution PH, keep the PH between 4 ~ 5, 85 °C water bath for 5h, filter drying, to obtain a powdered product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com