Minimally invasive method external wall insulation repairing process

A technology of exterior wall insulation and craftsmanship, which is applied in the direction of insulation, building maintenance, building components, etc., can solve the problems of separation of insulation layer and base wall, inconvenience for residents, and high maintenance cost, so as to reduce repair costs, save resources and Artificial, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The first step is to divide and mark the wall surface to determine the location of the external wall insulation defect and the repair location;

[0046] The second step is to determine the repair scope, repair area and mark the repair location;

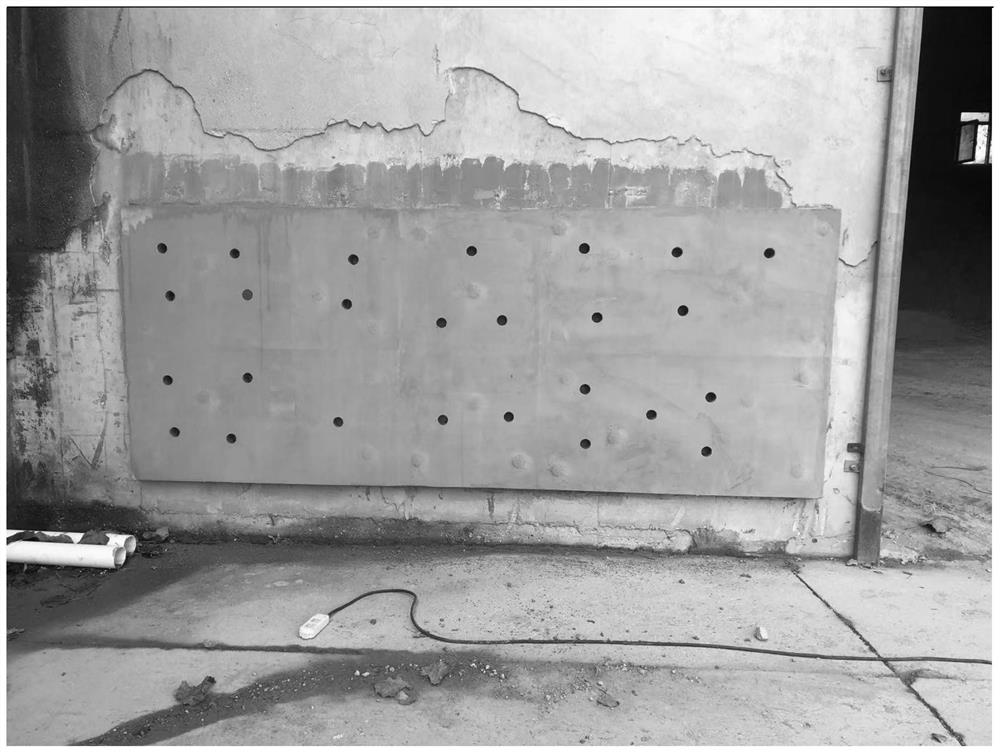

[0047] The third step is to design the position of the minimally invasive hole according to the repair position and area;

[0048] The fourth step is to design the position and quantity of anchor bolts according to the position of the minimally invasive hole;

[0049] The fifth step is to drill minimally invasive holes according to the design of the fourth step, and install the external wall anchors;

[0050]The sixth step is to fill the micro-expansion adhesive and block the minimally invasive hole with a matching plug;

[0051] The seventh step is to repair the finish layer.

[0052] In the step S1, the determination of the position of the thermal insulation defect and the repair position of the external wall is to first h...

PUM

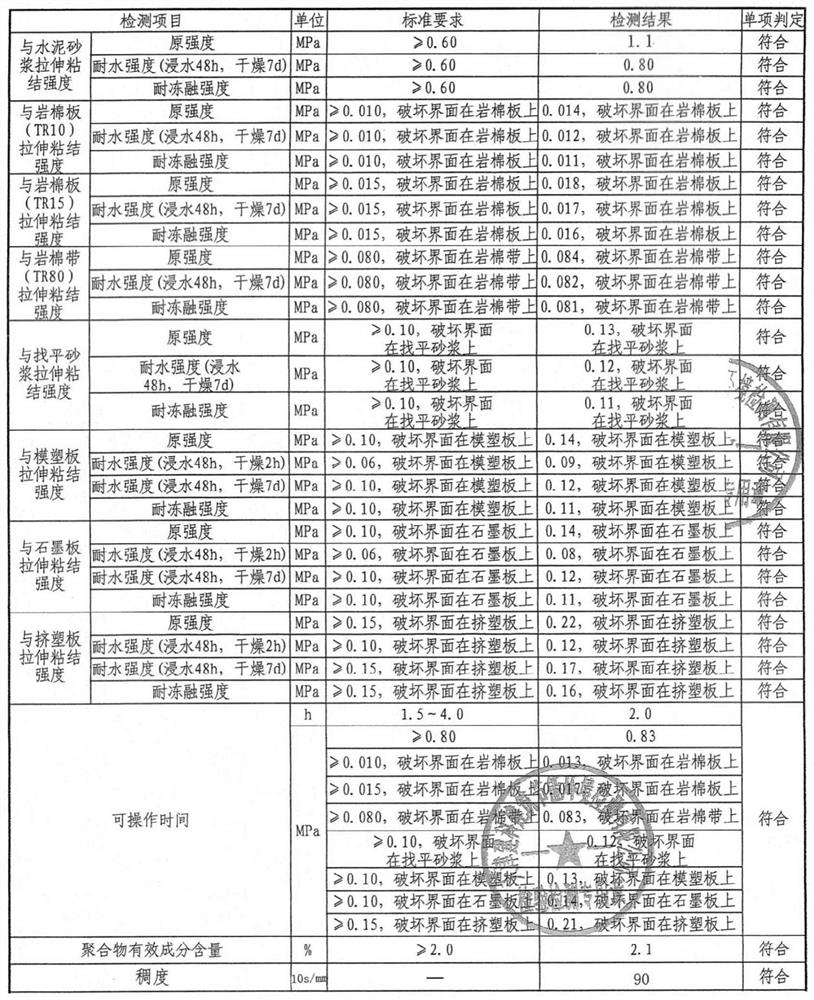

| Property | Measurement | Unit |

|---|---|---|

| flow consistency | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com