Environment-friendly construction waste separating and recycling device

A construction waste separation and recovery technology, applied in separation methods, solid separation, dispersed particle separation, etc., can solve problems such as polluting the environment, endangering the health of workers, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

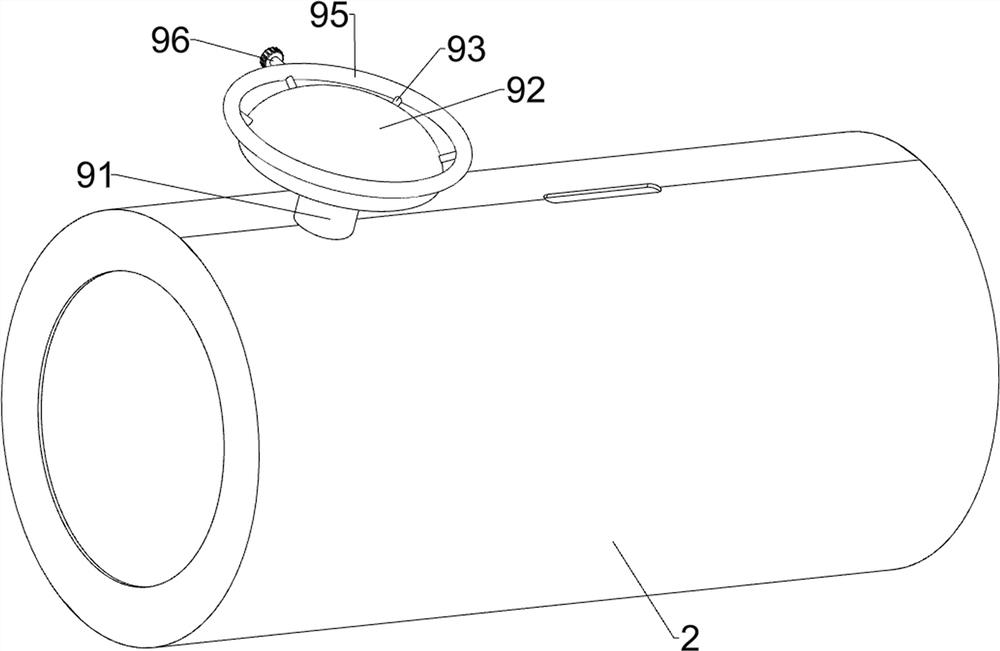

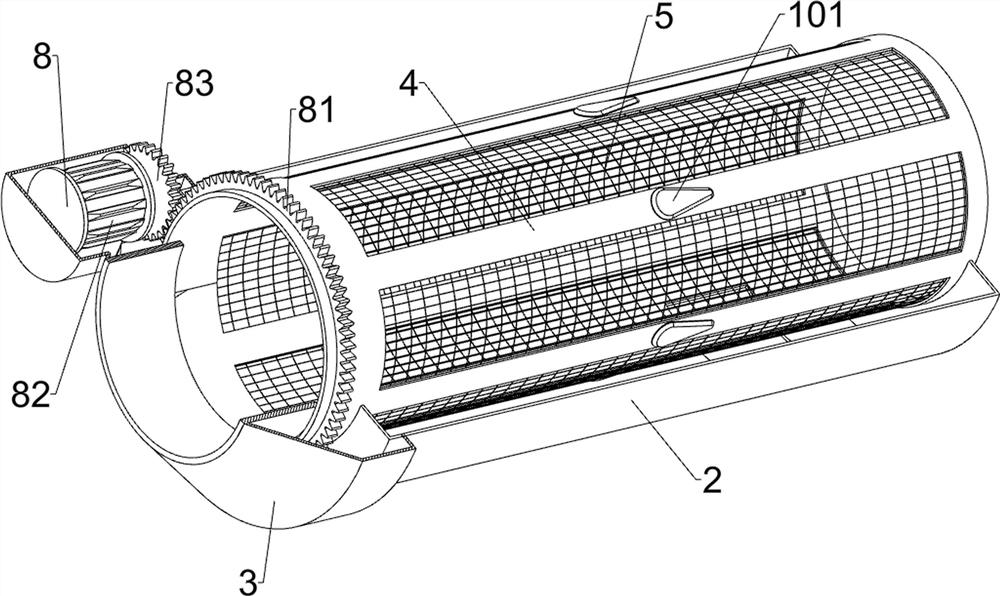

[0036] A kind of environment-friendly construction waste separation recycler, such as Figure 1-7 As shown, it includes installation frame 1, separation cylinder 2, installation shell 3, drum 4, filter screen 5, discharge hopper 6, discharge plate 7, drive mechanism 8 and dust discharge mechanism 9, and the upper part of installation frame 1 is provided with separation Cylinder 2, the separation cylinder 2 is installed on the installation frame 1 in an inclined state, which is convenient for construction waste to slide down. The left side of the separation cylinder 2 is welded with the installation shell 3. The bottom of the installation shell 3 is connected with the upper left side of the installation frame 1, and the separation cylinder 2 rotates inside The rotary drum 4 is provided with a circle of filter screens 5 evenly spaced on the rotary drum 4, the discharge hopper 6 is welded on the right side of the bottom of the separation drum 2, the discharge plate 7 is welded on ...

Embodiment 2

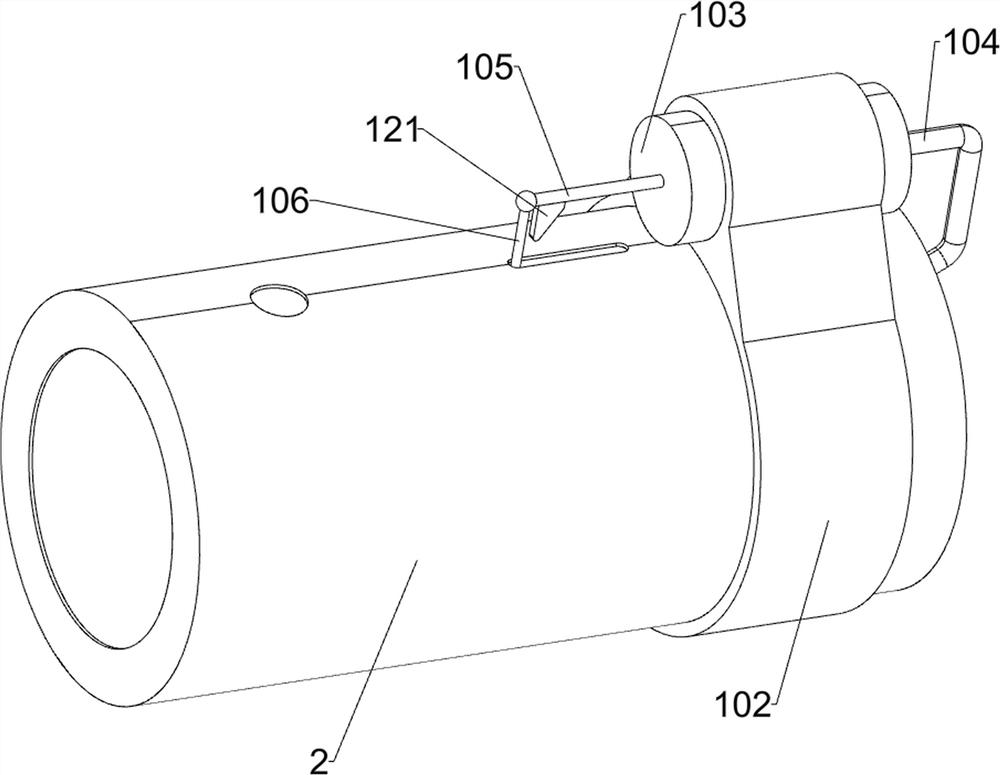

[0043] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, the blowing mechanism 10 is also included, and the blowing mechanism 10 includes a push block 101, a first mounting plate 102, a cylinder body 103, an air outlet pipe 104, a push rod 105, a vertical rod 106, a piston 107 and a first spring 108 , a circle of pushing blocks 101 are evenly spaced in the middle of the drum 4, a first mounting plate 102 is provided on the right side of the separation drum 2, a cylinder block 103 is embedded in the upper part of the first mounting plate 102, and an air intake pipe is provided on the rear side of the cylinder block 103 , the intake pipe has a check valve, the right side of the cylinder body 103 is welded with an outlet pipe 104, the outlet pipe 104 has a check valve, the left part of the cylinder body 103 is slidingly provided with a push rod 105, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com