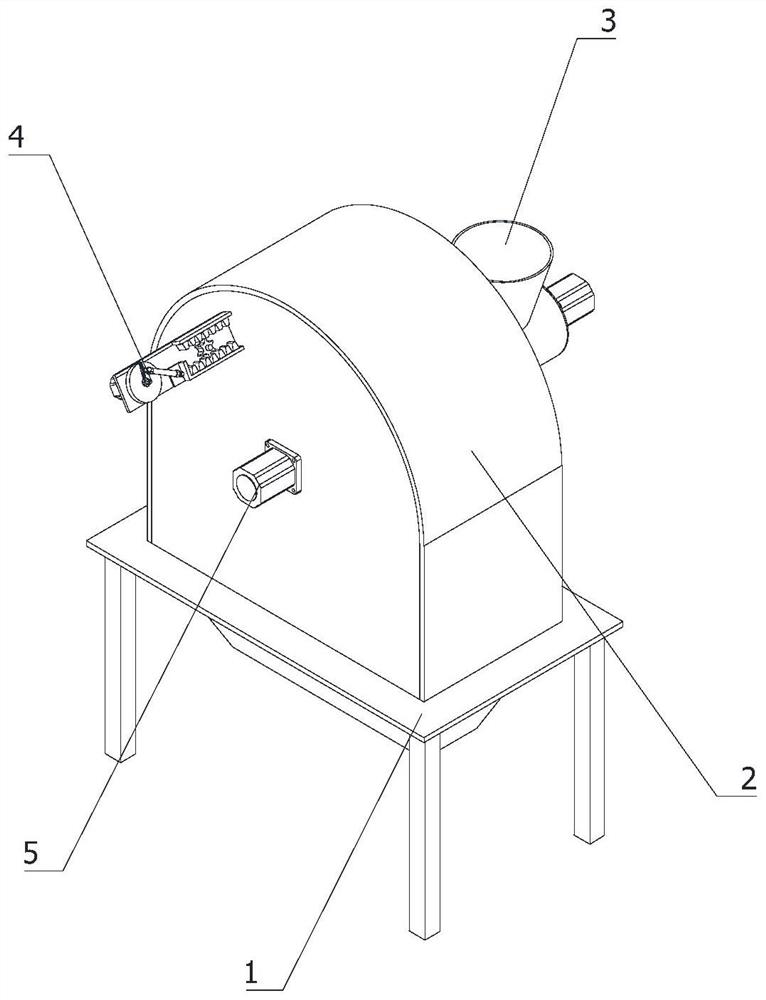

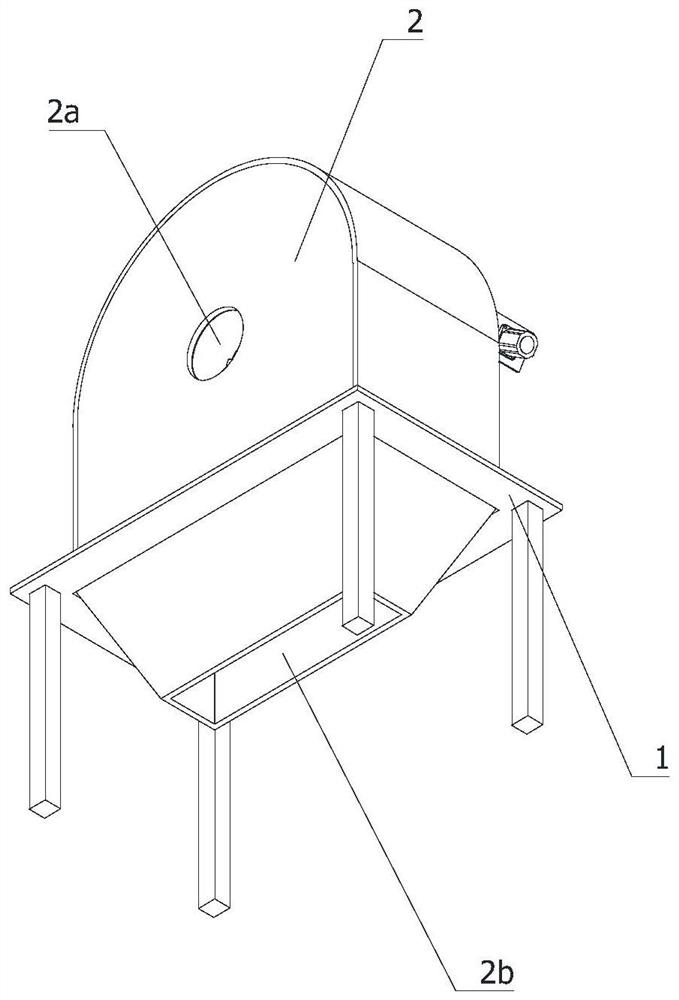

Automatic extraction and concentration equipment for nutritional rice syrup

An automatic extraction and nutritional rice technology, applied in grain processing and other directions, can solve the problems of inability to meet screening and fine grinding, and achieve the effects of increasing friction coefficient, increasing stability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

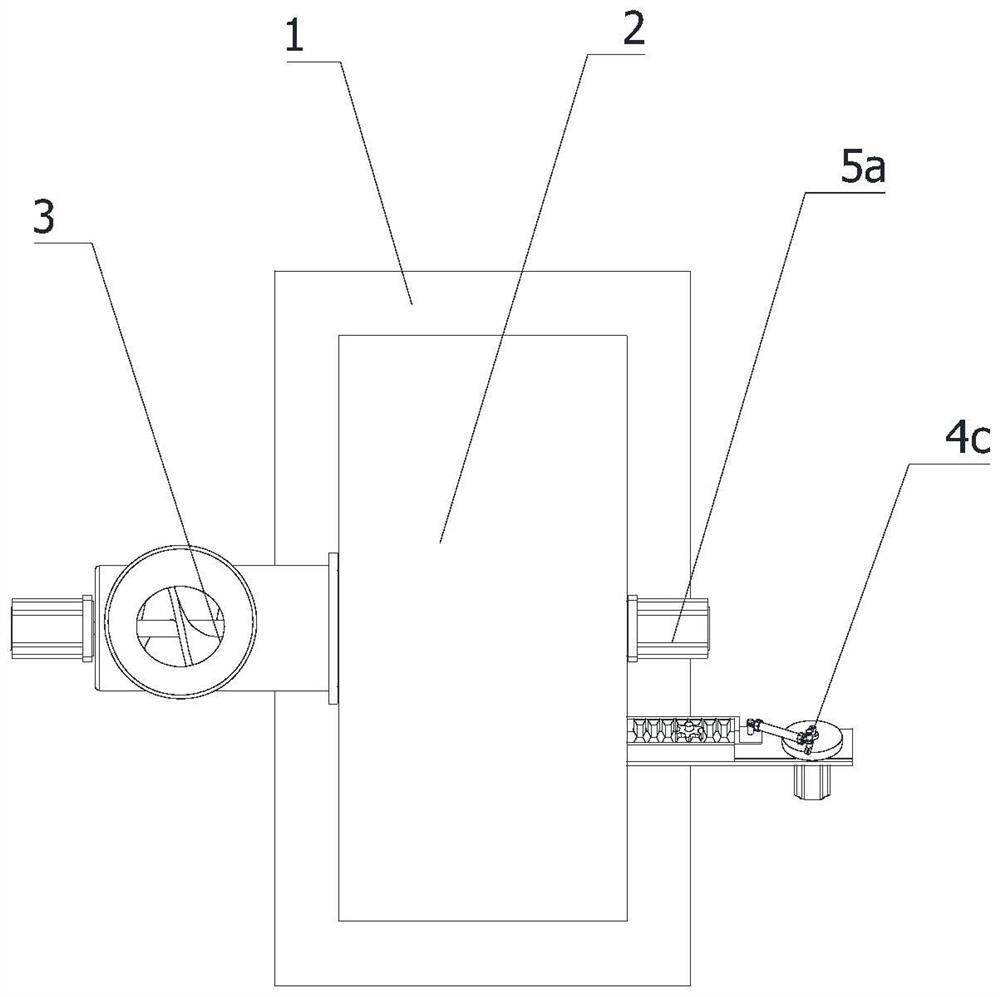

[0065] In the first embodiment, the technical problem that this application intends to solve is to drive the first filter screen 4a and the second filter screen 4b to move horizontally through the screening assembly, so that the first filter screen 4a and the second filter screen 4b can be better Sieve the crushed material. For this reason, the application starts the third rotary driver 4c1, the output shaft of the third rotary driver 4c1 drives the rotation of the second rotary shaft 4c4 fixedly connected with it, and the rotation of the second rotary shaft 4c4 drives the first rotary shaft 4c4 fixedly connected with it. The rotation of the gear 4c2 drives the movement of the two first racks 4c5 meshed with it through the rotation of the first gear 4c2, thereby respectively driving the first filter screen 4a and the second filter screen 4b through the two first racks 4c5 Movement, through the forward rotation and reverse rotation of the third rotary driver 4c1, the first gear...

no. 2 example

[0068] In the second embodiment, the technical problem that this application intends to solve is to drive the first filter screen 4a and the second filter screen 4b to move horizontally through the screening assembly, so that the first filter screen 4a and the second filter screen 4b can be better Sieve the crushed material. For this reason, the application starts the fourth rotary driver 4c6, the output shaft of the fourth rotary driver 4c6 drives the rotation of the turntable 4c11 fixedly connected with it, and the rotation of the turntable 4c11 drives the second fixed shaft 4c12 connected with it to move along its axis. The second fixed shaft 4c12 drives the movement of the connecting rod 4c15, thereby driving the linear reciprocating motion of one of the second racks 4c10 connected to it through the connecting rod 4c15, because the second gear 4c7 and the two second racks 4c10 Mesh connection, so the movement of one of the second racks 4c10 drives the rotation of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com