High-energy-density sodium ion battery

A sodium-ion battery, high energy density technology, applied in the manufacture of battery electrodes, secondary batteries, electrolyte batteries, etc., can solve the problems of low energy density, low Coulomb efficiency, and insufficient capacity of low-potential platforms in sodium-ion batteries, and achieves the goal of advancing The commercialization process, the low reaction temperature, the effect of solving the low first coulombic efficiency and the insufficient capacity of the low potential platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

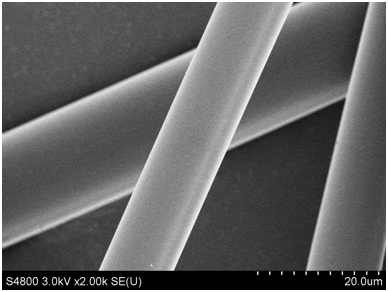

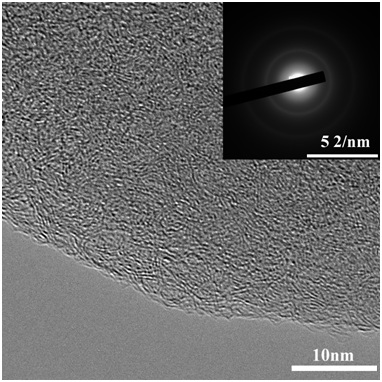

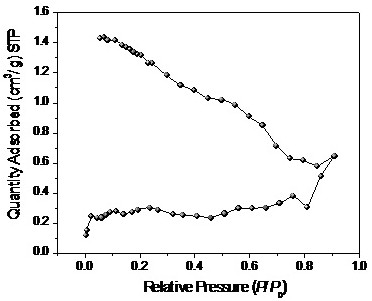

[0037] This embodiment provides a high-energy-density sodium-ion battery, including a positive electrode, a negative electrode, and an electrolyte, wherein the active material of the negative electrode is a hard carbon material with abundant nanopores and a pore size smaller than 0.4 nm.

[0038] The preparation method of the hard carbon negative electrode material at least comprises the following steps:

[0039] In the first step, microporous activated carbon (precursor is bitumen, specific surface area is 1313m 2 / g) into a tube furnace, the flow rate is 90mL / min protective gas argon, and the temperature is raised to a final temperature of 900°C at a heating rate of 5°C / min;

[0040] In the second step, under the final temperature condition of 900°C, methane gas with a flow rate of 10mL / min is introduced to carry out chemical vapor deposition;

[0041] In the third step, after constant temperature reaction for 1 hour, the methane gas was cut off, and the temperature was low...

Embodiment 2

[0047] The difference with embodiment 1 is:

[0048] In the preparation method of the hard carbon negative electrode material, methane gas is cut off after constant temperature reaction for 5 hours; the rest is the same as that of Example 1, and will not be repeated here.

Embodiment 3

[0050] The difference with embodiment 1 is:

[0051] In the preparation method of the hard carbon negative electrode material, the microporous activated carbon YP80 (the precursor is coconut shell, the specific surface area is 2538 m 2 / g) into a tube furnace, after a constant temperature reaction for 10 hours, cut off the methane gas; the rest is the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com