Hydraulic transmission control system

A technology of hydraulic transmission and control system, which is applied in transmission control, fluid pressure actuation device, fluid transmission device, etc., can solve the problem of locking delay, low reliability and stability, and inability to completely lock the cylinder piston rod. Shrinkage and other problems, to ensure reliable and stable work, reliable and stable disconnection or engagement, and prevent hydraulic oil from flowing backwards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

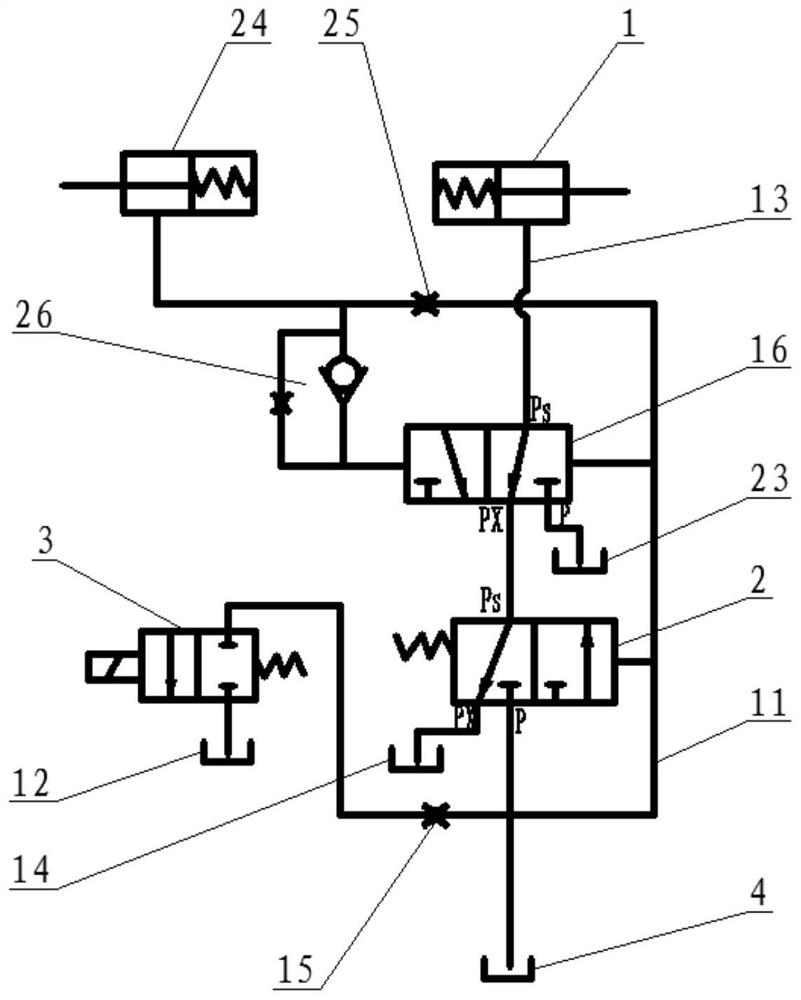

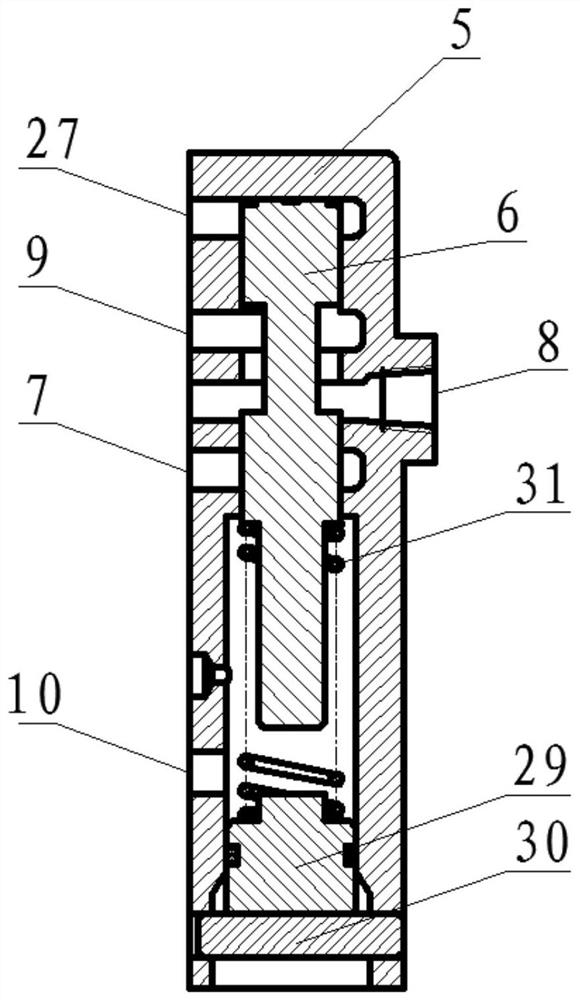

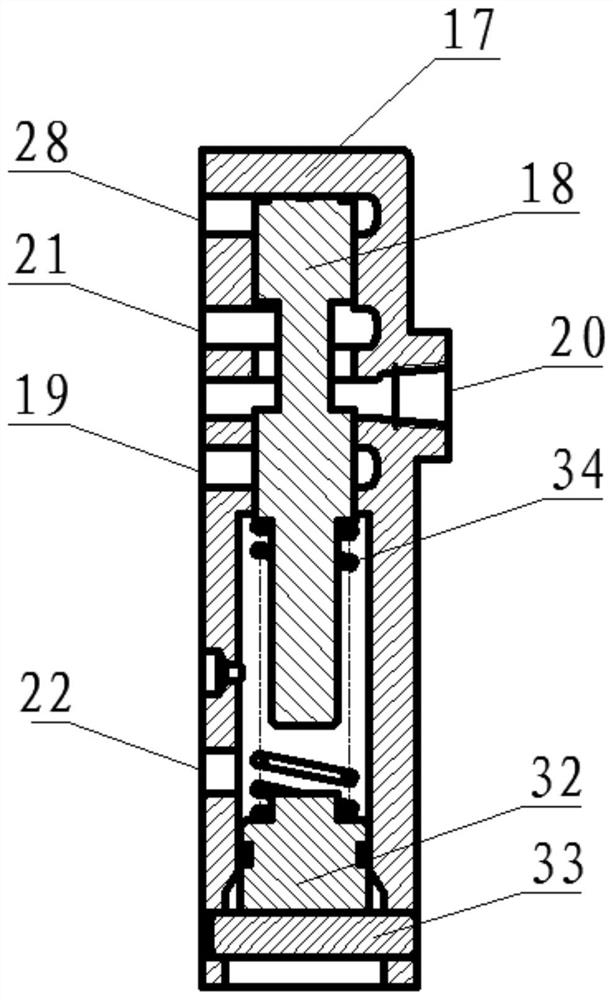

[0021] Such as Figure 1 to Figure 3 As shown, the present invention provides a hydraulic transmission control system, including a lock-up oil cylinder 1, a lock-up valve 2, a solenoid valve 3 and a source oil tank 4, the piston rod of the lock-up oil cylinder 1 is connected with the hydraulic transmission through a friction clutch, and locked Valve 2 includes a valve body A5 and a spool A6. The valve body A5 is provided with an oil inlet Pa7, an oil outlet Psa8, an oil drain Pxa9 and an oil control port Pda10. The oil outlet Psa8 communicates with the oil drain Pxa9 to form an oil drain Channel A, the oil inlet Pa7 communicates with the oil outlet Psa8 to form an oil inlet channel A, the valve core A6 is accommodated in the valve body A5 and through its own reciprocating motion, the oil drain channel A and the oil inlet channel A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com