Aluminum profile surface etching device and method

A technology for surface etching and aluminum profiles, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. Avoid the effects of excessive etching, low technical requirements, and few etching steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

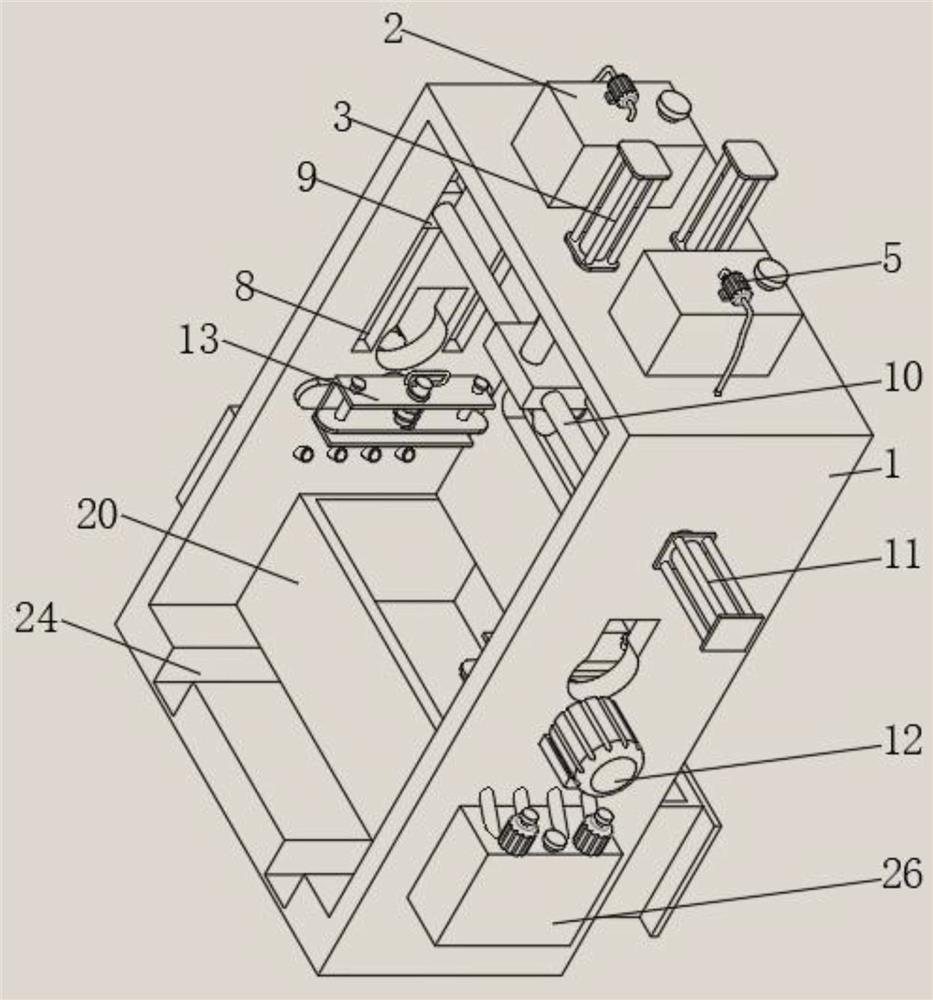

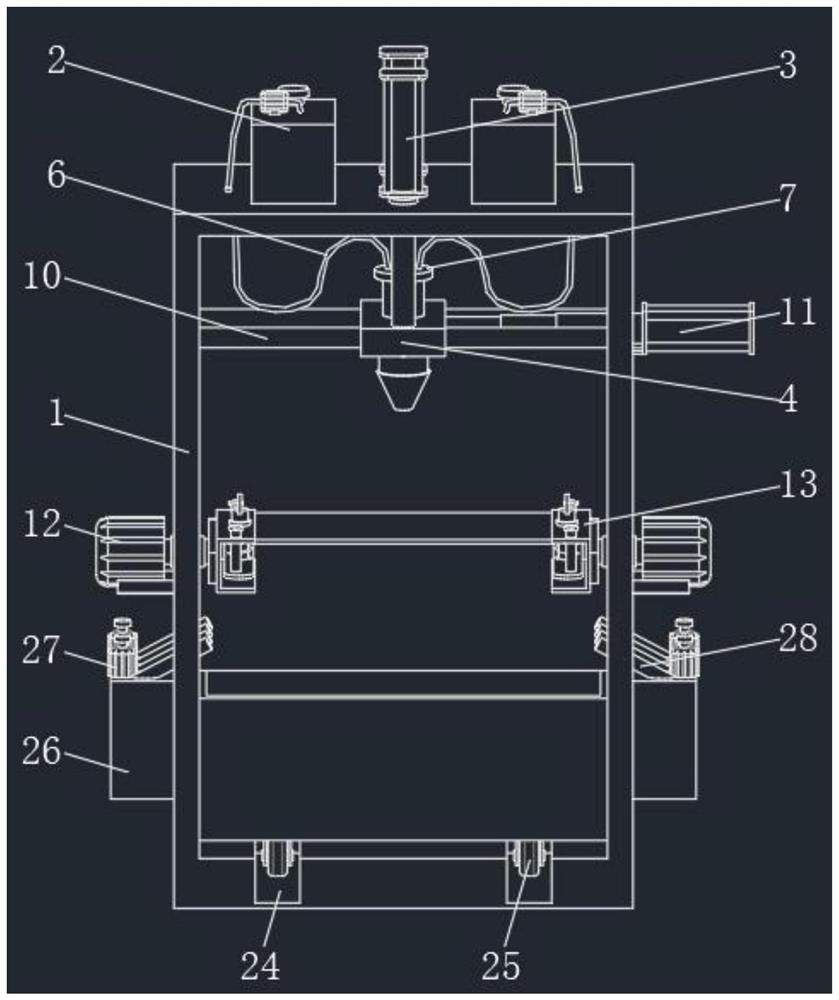

[0032] see figure 1 and Figure 4 , the present invention provides the following technical solutions: an aluminum profile surface etching device, including an etching box 1, an etching liquid tank 2, a liquid guide hose 6 and an etching gun 7, and the inside of the etching box 1 is connected with a guide assembly , the top of the etching liquid tank 2 is connected with a water pump 5, and one end of the water pump 5 is connected with one end of the liquid guide hose 6, the middle part of the etching box 1 is connected with a clamping mechanism, and the etching box Both surfaces of 1 are connected with driving motor 12, and the driving end of driving motor 12 is connected with the clamping mechanism. There are cleaning facilities.

[0033] Specifically, the clamping mechanism includes a C-shaped plate 13, a pulling rod 15, a clamping plate 16, a pulling ring 17, a spring 18 and a guide rod 19, and the back of the C-shaped plate 13 is fixedly connected with an engaging plate 1...

Embodiment 2

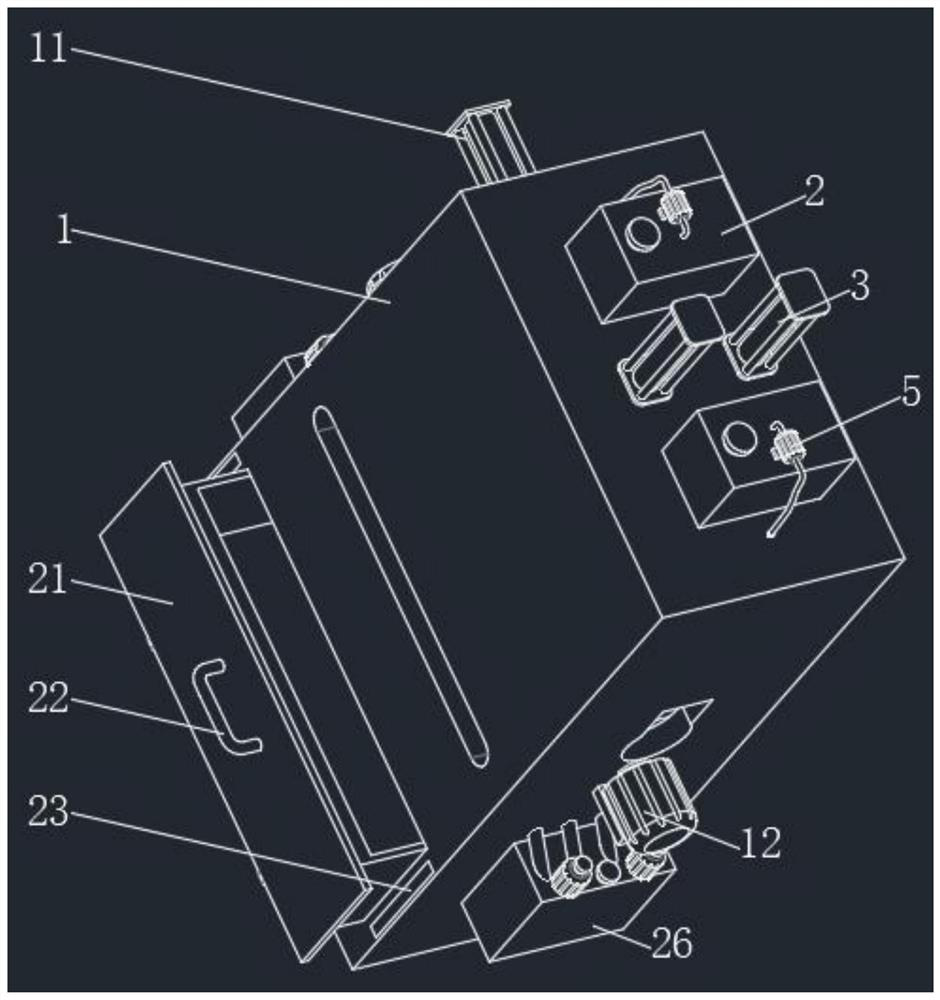

[0036] Specifically, the collection part includes a collection box 20 and a pulling plate 21, and the pulling plate 21 is fixedly connected to the collection box 20, and the collection box 20 is inserted in the back of the etching box 1, and is located at the inner bottom of the etching box 1, A pulling handle 22 is fixedly connected to the surface of the pulling plate 21 , and a magnetic strip 23 is inlaid on the back of the etching box 1 .

[0037] Specifically, a roller groove 24 is connected to the bottom of the collection box 20 , and a rolling wheel 25 is provided on the inner bottom wall of the etching box 1 ;

[0038] In this embodiment, during the entire etching process, excess etching solution will drip into the inside of the collection box 20, and after the collection box 20 is filled with a certain amount, the pull plate 21 and the collection box 20 can be pulled by pulling the handle 22, Thereby let collecting box 20 cooperate rolling wheel groove 24 and rolling w...

Embodiment 3

[0040] Specifically, the cleaning equipment includes a water tank 26, an air pump 27 and an inclined water spray pipe 28. The water tank 26 is connected to the side of the etching box 1, the air pump 27 is fixedly connected above the water tank 26, and the inclined water spray pipe 28 is connected to the water tank. 26; and the inclined spray pipe 28 runs through the side of the etching box 1 and the upper wall of the water tank 26 respectively.

[0041] Specifically, the guide assembly includes a first hydraulic cylinder 3, a movable block 4, a guide chute 8, a guide slider 9, a cross bar 10 and a second hydraulic cylinder 11, and the first hydraulic cylinder 3 is fixedly connected to the etching box 1, the movable block 4 is connected to the output end of the first hydraulic cylinder 3, the guide chute 8 is provided on the inner side wall of the etching box 1, the guide slider 9 is slidably connected on the inner wall of the guide chute 8, and the cross bar 10 It is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com