Marine diesel engine main propulsion control device

A marine diesel engine and propulsion control technology, applied in the direction of ship propulsion, propulsion engine, electromechanical device, etc., can solve the problems of high difficulty, high fuel consumption and emission, and low thermal efficiency, so as to improve performance defects, solve saturation problems, and improve position The effect of maintaining ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

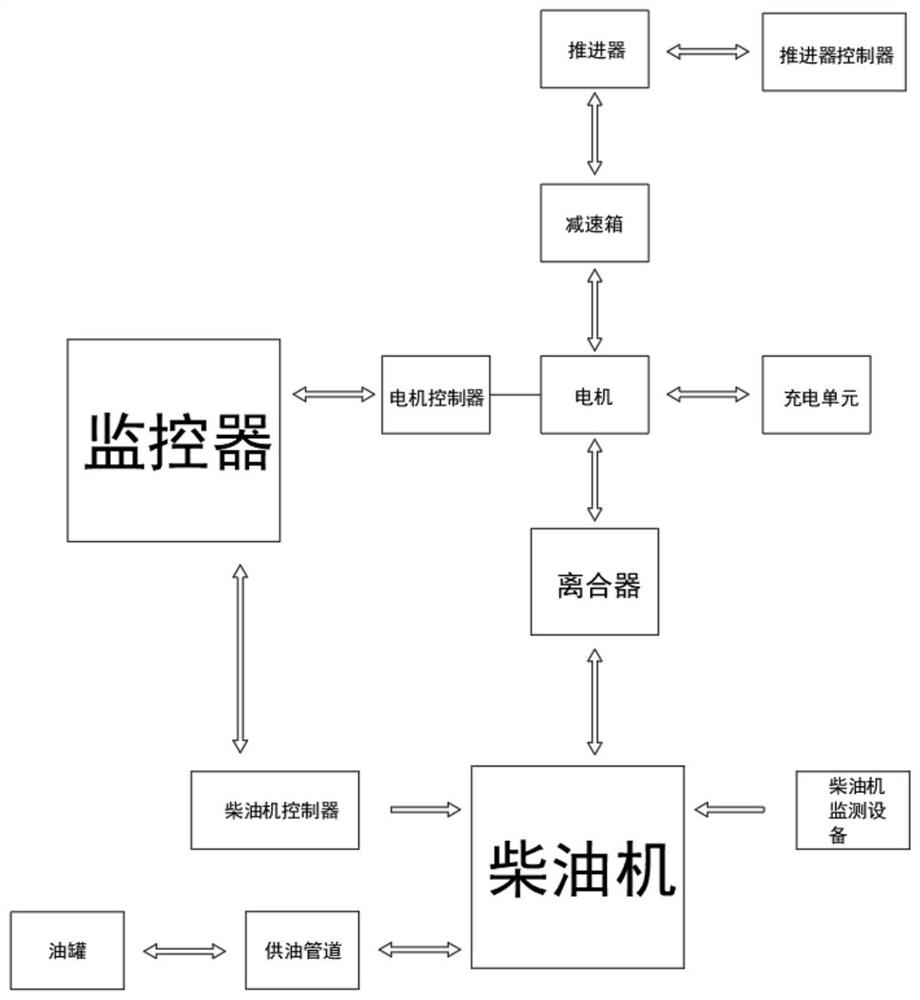

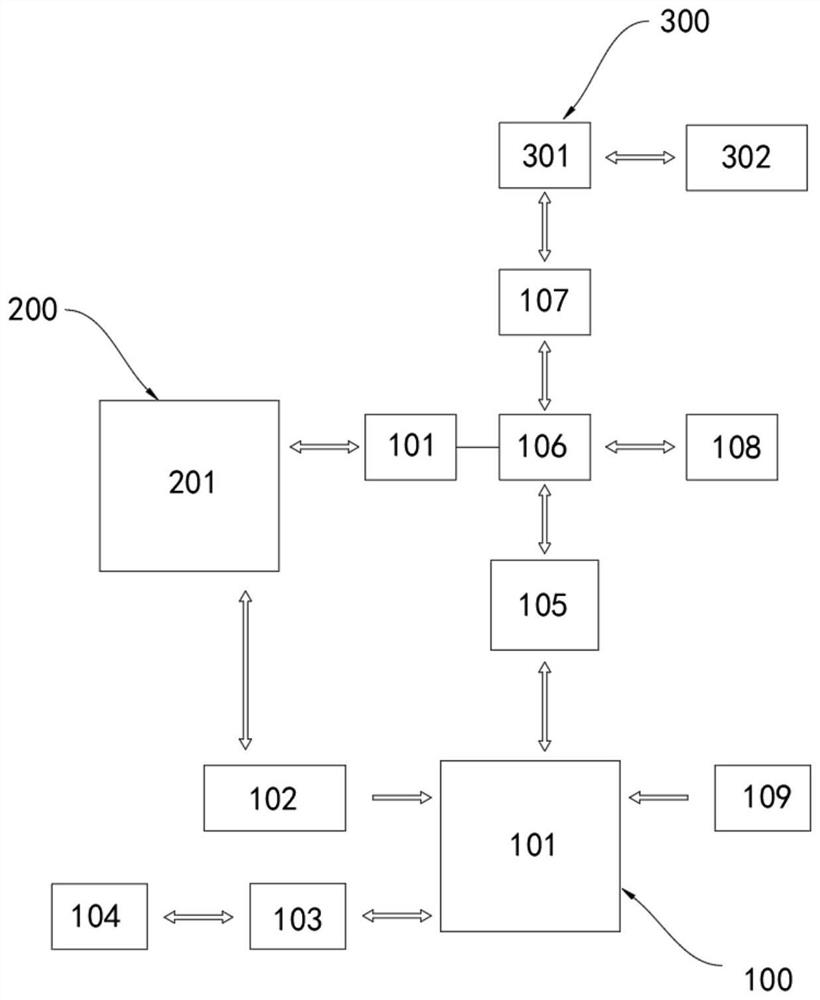

[0022] refer to Figure 1-3 , a marine diesel engine main propulsion control device, comprising: a diesel engine assembly 100, a monitoring assembly 200 and a propulsion assembly 300, the diesel engine assembly 100 includes a diesel engine body 101, a diesel engine controller 102 is arranged outside the diesel engine body 101, the side wall of the diesel engine body 101 The oil supply pipeline 103 connected with it is connected to the top, and the input end of the oil supply pipeline 103 is connected with the external oil tank 104; the output end of the diesel engine body 101 is connected with a clutch 105, and the output end of the clutch 105 is connected with a motor 106, specifically Yes, the outer side of the motor 106 is provided with a charging unit 108 connected thereto, the input end of the charging unit 108 is connected to the remote power grid, the output end of the charging unit 108 is connected to the motor 106, and the motor 106 is connected to the propulsion assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com