Scrap steel batching method for converter smelting

A converter smelting and scrap steel technology, applied in the field of steelmaking, can solve the problems of complex batching method, large workload, small workload, etc., achieve the effect of scientific and reasonable batching method, solve the scrap steel batching, and reduce the iron-steel ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

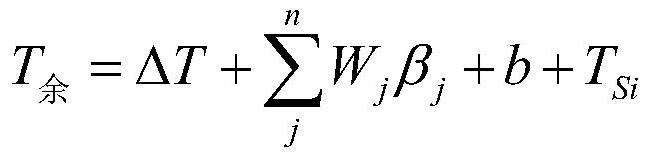

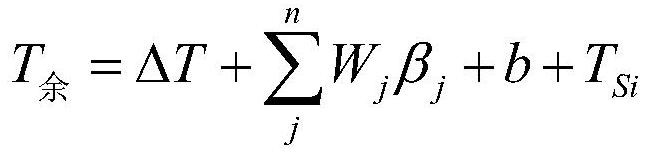

[0143] According to a preferred embodiment of the present invention, the method also includes:

[0144] (4) According to the steel scrap type selected in step (3) and its addition ratio and the addition amount of different types of steel scrap obtained, the iron-steel ratio is calculated;

[0145] (5) Select a plurality of groups of initial data, each group of initial data includes the steel scrap type selected in step (3) and its addition ratio, and repeats step (4);

[0146] (6) Select the group with the lowest iron-to-steel ratio in step (5) as the batching scheme.

[0147] In the above-mentioned preferred solution of the present invention, the iron-steel ratio can be calculated according to the selected initial data, and then the initial data can be changed to optimize the composition of scrap steel batching by comparing the obtained iron-steel ratio.

[0148] It should be understood that the iron-to-steel ratio refers to the amount of molten iron divided by the amount of...

Embodiment 1

[0157] Taking the production of HRB400 as an example, the temperature of molten iron is 1350°C, and the mass percentage of Si in the molten iron is 0.4%. Among them, 9 tons of scrap steel are added to the molten iron tank, and the temperature of scrap steel in the molten iron tank is raised to 750°C by blast furnace gas baking, and then 9 tons of scrap steel are added. The amount of molten iron for steel scrap is 119t, and the furnace temperature is known to be 1640°C according to empirical values. According to the cost performance ranking of scrap steel in Table 1 and the actual situation in the factory, the types of scrap steel were comprehensively selected as pig iron (92% yield), heavy waste (94% yield), steel bar briquettes (94% yield), and shaving briquettes (yield rate 91%), industrial briquetting (yield rate 88%), recycled steel scrap (yield rate 35%, referring to the scrap steel produced in the company's production process, specifically structural frames and scrap equi...

Embodiment 2

[0178] Taking the production of HRB400 as an example, the temperature of molten iron is 1350°C, and the mass percentage of Si in the molten iron is 0.4%. Among them, 9 tons of scrap steel are added to the molten iron tank, and the temperature of scrap steel in the molten iron tank is raised to 750°C by blast furnace gas baking, and then 9 tons of scrap steel are added. The amount of molten iron for steel scrap is 119t, and the furnace temperature is known to be 1640°C according to empirical values. According to the cost-effective sorting of scrap steel in Table 1 and the actual situation in the factory, only steel bar briquettes (94% yield) were selected as scrap steel ingredients, 4.5t of lime and 1.5t of magnesium balls were added. There is no need to supplement external heat, and the molten iron, scrap steel and flux in the converter form a critical heat balance. The total amount of steel scrap added, the amount of various types of added steel and the iron-steel ratio are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com