Equipment and method for lifting and filling low-temperature geothermal water source in same well

A low-temperature, geothermal technology, applied in geothermal power generation, collectors using groundwater as working fluid, etc., can solve the problems of short geological contact time, insufficient heating, and few recharge layers, etc., to increase the contact distance and Area, energy consumption reduction, the effect of prolonging the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

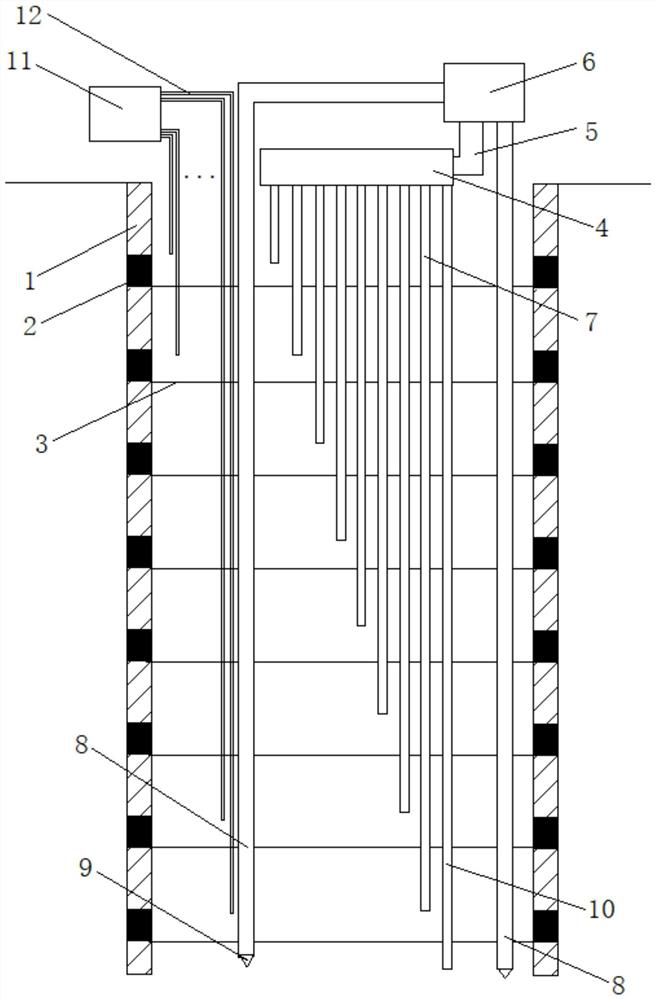

[0031] Embodiment 1: the well pipe 1 with a length of 130 meters, a well diameter of 0.8 meters, and a well pipe of 0.42 meters is drilled underground to the aquifer, and the well distance is greater than or equal to 100 meters. , the 30th meter, the 45th meter, the 60th meter, the 75th meter, the 90th meter, the 105th meter, and the 120th meter are respectively provided with a metal clapboard 3 to form a water-resistant layer, so that the well pipe forms eight levels. Each level of well pipe is connected by solid pipe 1 and mesh pipe 2. The solid pipe 1 is the well pipe without through holes in the pipe wall; the mesh pipe 2 is the well pipe with multiple through holes in the pipe wall; the diameter design of the through holes It is 1-2cm. This design is because the weight of the water brings a certain pressure, so that the silt in the well pipe is easy to discharge outside the pipe and does not stay in the well pipe; The effect will return to the pipe wall, but will bring m...

Embodiment 2

[0037] A well pipe with a length of 180 meters, a well diameter of 1 meter, and a diameter of 0.5 meters is lowered underground to the aquifer by drilling technology, and the well spacing is greater than or equal to 100 meters. The 45th, 65th, 85th, 105th, 125th, 145th, and 165th meters are respectively provided with a metal partition 3 to form a water-resisting layer, so that the well pipe forms eight stages. Each level of well pipe is connected by solid pipe 1 and mesh pipe 2. The solid pipe 1 is the well pipe without through holes in the pipe wall; the mesh pipe 2 is the well pipe with multiple through holes in the pipe wall; the diameter design of the through holes It is 1-2cm. This design is because the weight of the water brings a certain pressure, so that the silt in the well pipe is easy to discharge outside the pipe and does not stay in the well pipe; The effect will return to the pipe wall, but will bring more sediment, which is not as effective as the aforementione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com