Energy storage device for boiler waste heat recovery

A technology of energy storage device and boiler waste heat, applied in boiler cleaning device, boiler support/positioning device, steam boiler, etc., can solve the problems of difficult boiler waste heat recovery, large fuel consumption, waste of resources, etc., and achieve good sealing effect, volume The effect of reducing and increasing the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

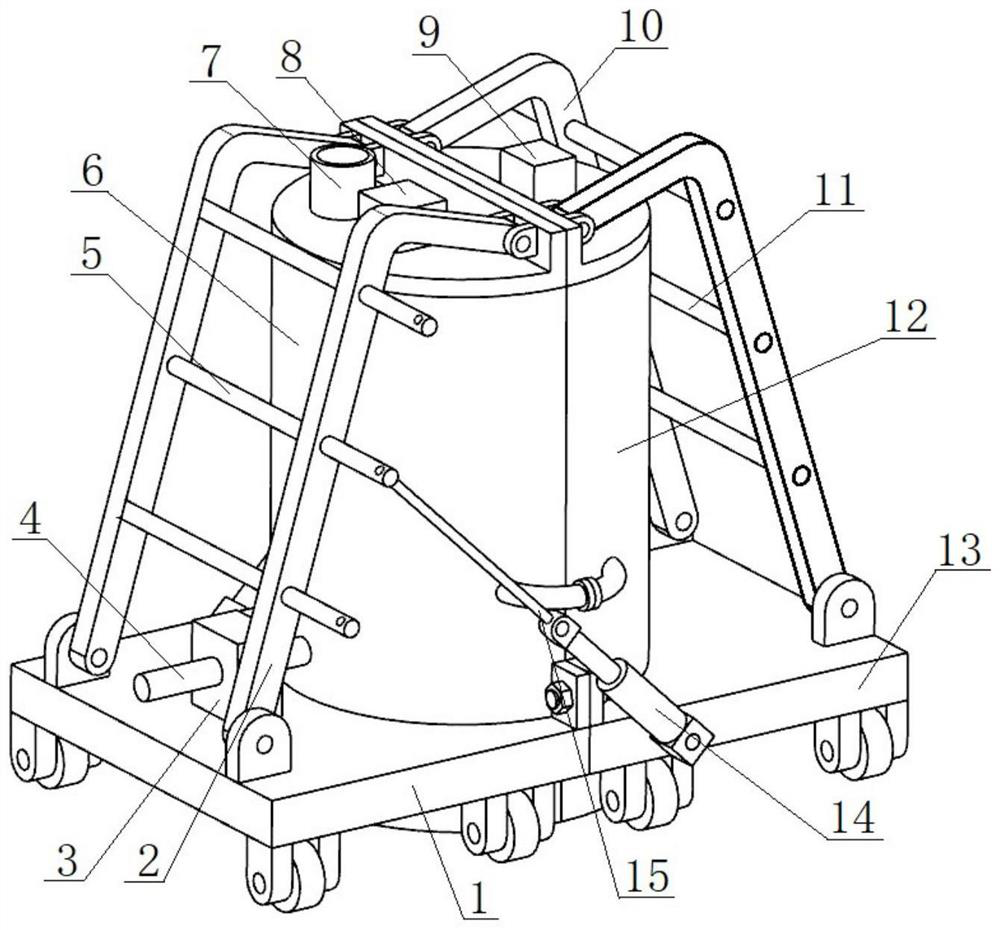

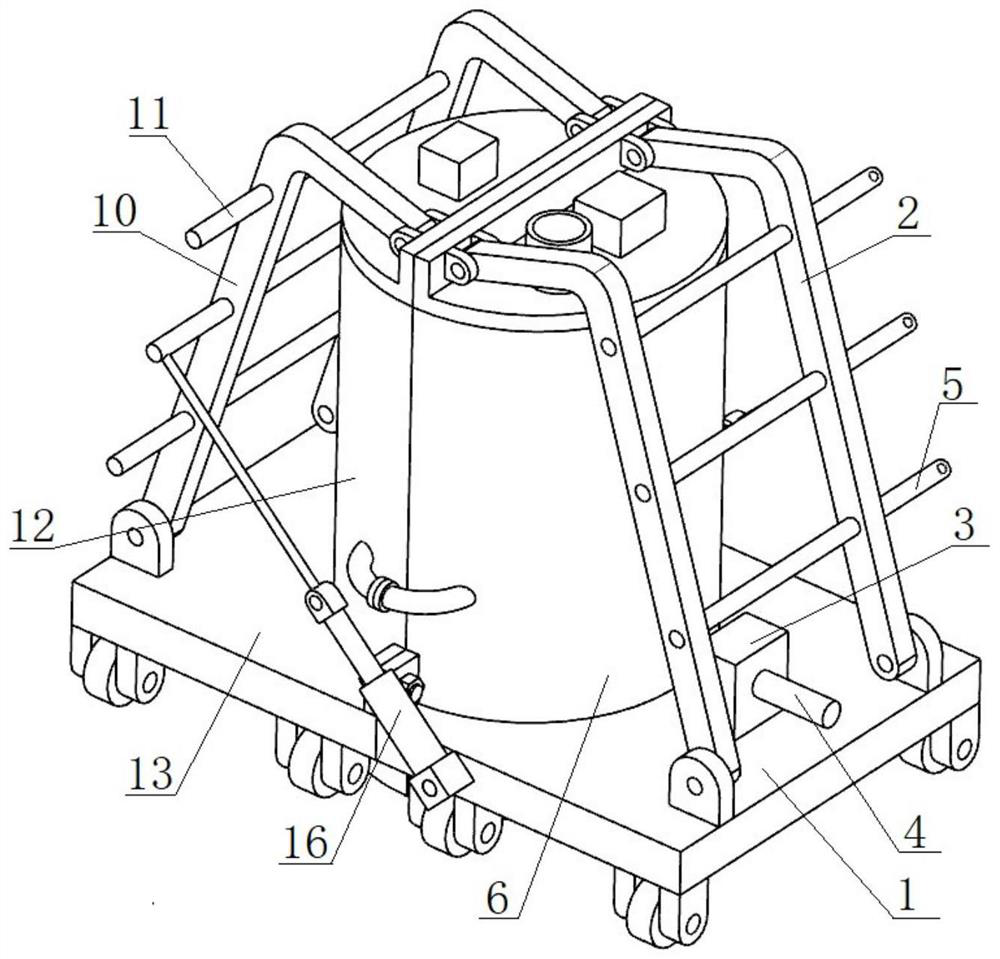

[0027] see figure 1 , figure 2 and Figure 4 , an energy storage device for recovery of boiler waste heat, comprising two closed structure 1 and closed mechanism 2 which can be connected to each other, and forms a closed space, a boiler is arranged in the closed space, a thermoelectric power generation component is arranged in the closed space, and the closed structure 1 A steam component is also arranged in the second closed structure and the closed structure respectively.

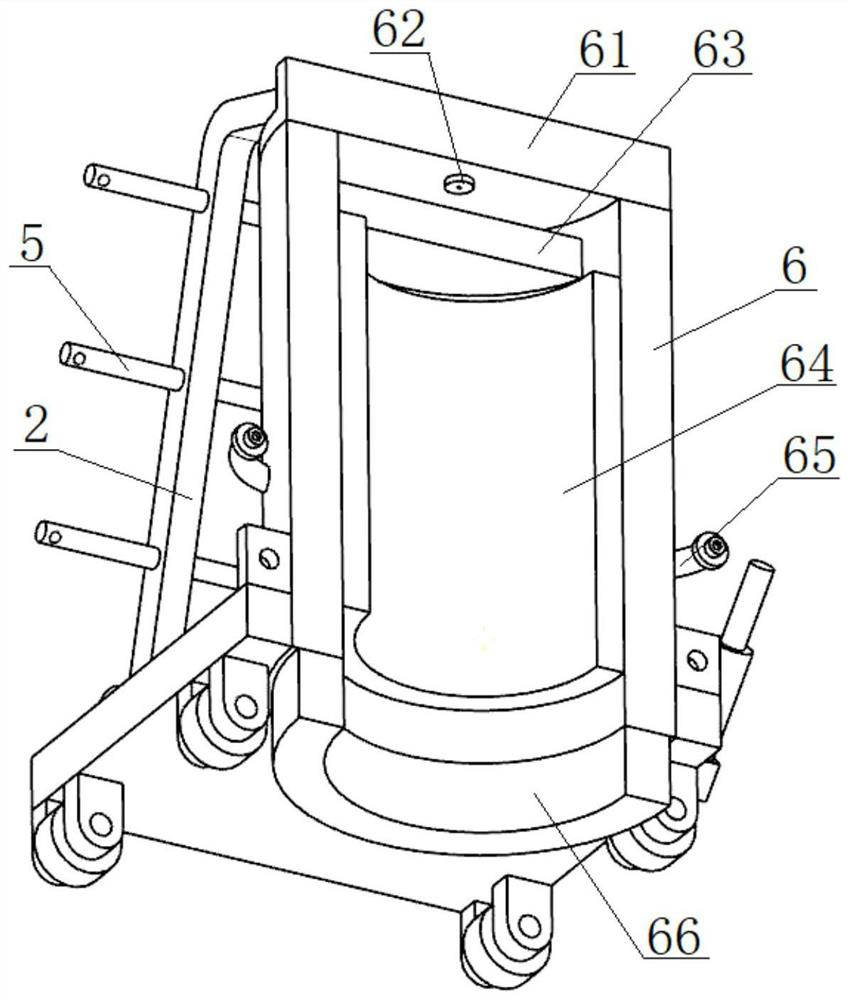

[0028] see image 3 The closed structure-includes a bottom plate-1 arranged horizontally, an arc-shaped cover-6 vertically arranged on the bottom plate-1, an upper air bag-64 arranged inside the arc-shaped cover-6, and an upper airbag-64 arranged on the top end of the arc-shaped cover-6 The top cover one 61, the bottom end surface of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com