Static pressure supporting servo hydraulic cylinder

A servo hydraulic cylinder and static pressure support technology, applied in the field of servo hydraulic cylinders, can solve problems such as economic loss, fatigue of platform surface materials, and danger to the life safety of staff, so as to reduce potential safety hazards, avoid fracture risks, and ensure strength and thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

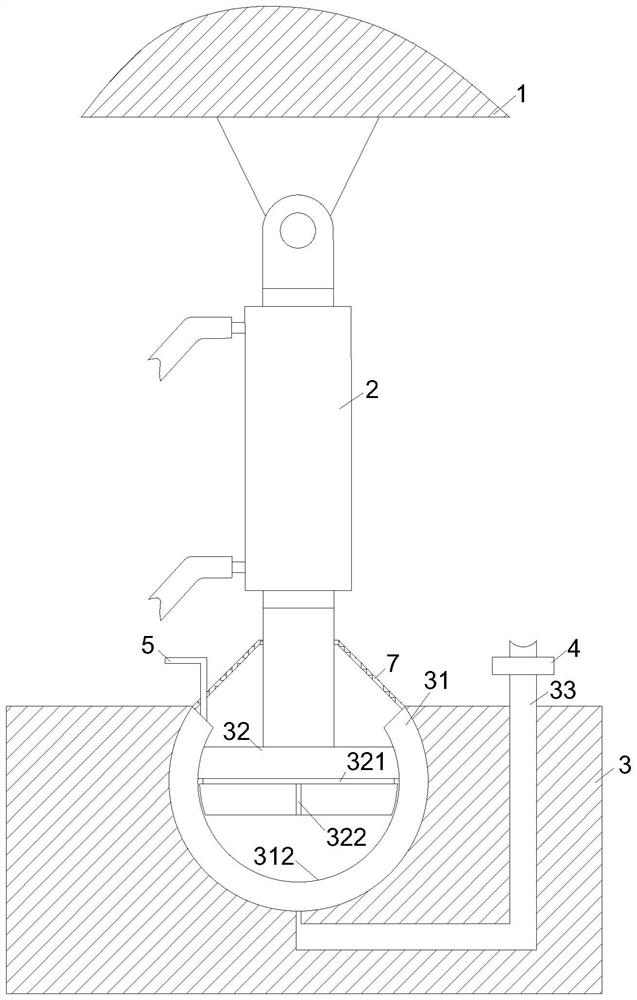

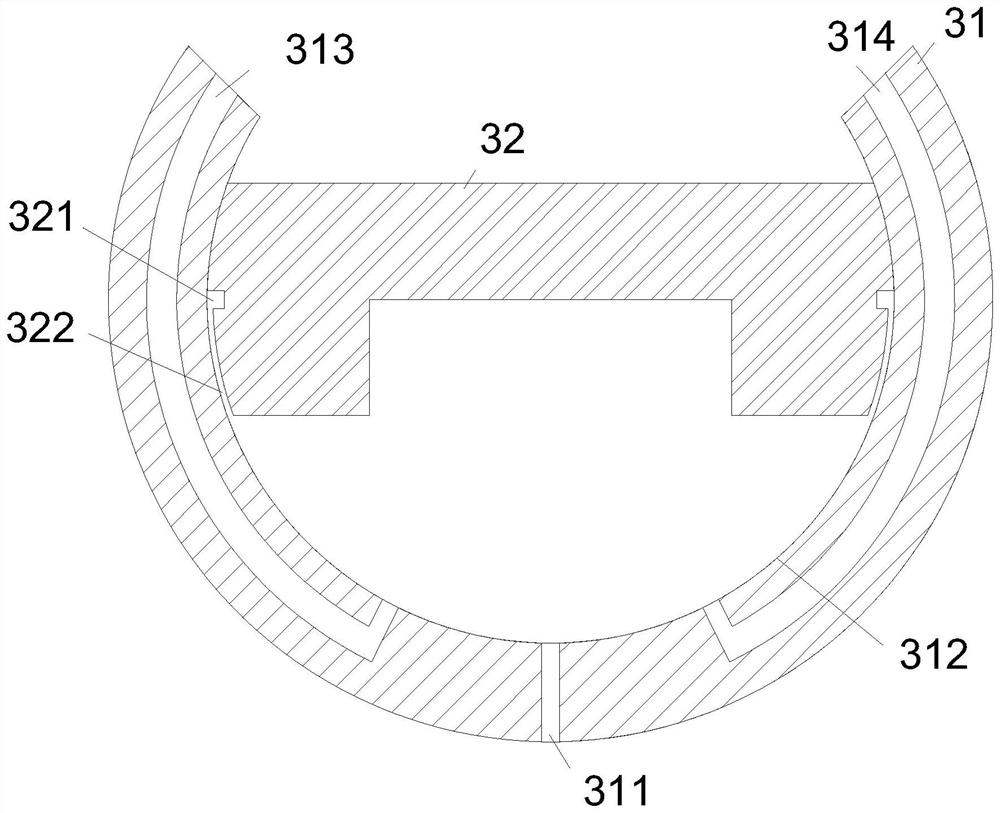

[0031] As an embodiment of the present invention, the inside of the hemispherical housing 31 and the bottom of the drum-shaped support plate 32 form an oil cavity 312, and a horizontal oil groove 321 is opened at the maximum diameter of the side surface of the drum-shaped support plate 32, and the oil cavity 312 and the horizontal oil groove 321 Connected by several longitudinal oil grooves 322, the depth of the longitudinal oil grooves 322 is shallower than the horizontal oil grooves 321;

[0032]The oil in the oil chamber 312 flows into the horizontal oil groove 321 along the longitudinal oil groove 322, and the horizontal oil groove 321 is opened at the largest diameter to distribute the force evenly and play a role in lubrication. The oil can share a part of the drum-shaped support plate 32 Under the pressure, the oil will lubricate the contact point between the drum-shaped support plate 32 and the hemispherical shell 31 with the movement, and achieve the effect of lubricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com