Deep hole comprehensive guarantee method and equipment for geological exploration

A technology for comprehensive protection and geological exploration, applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve the problems of large casing stress, affecting the protection effect of deep holes, distortion, etc., and achieve the effect of avoiding collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

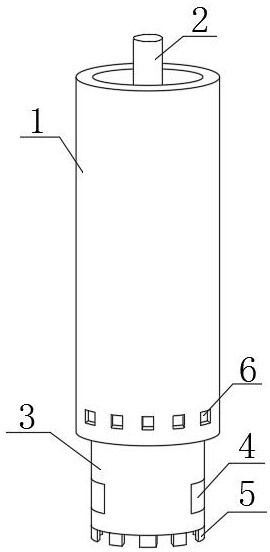

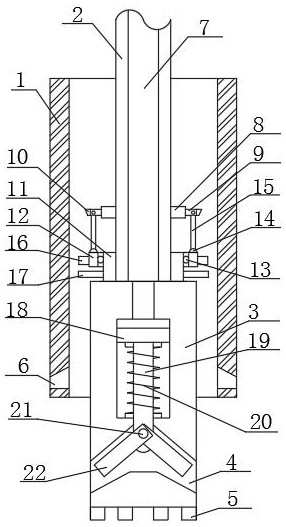

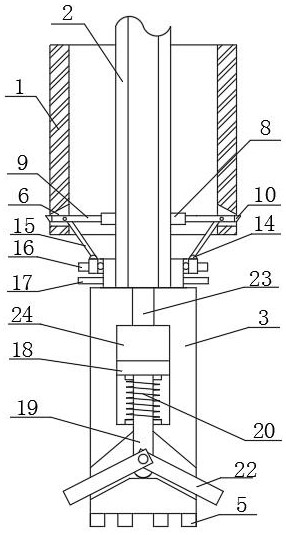

[0031] Such as Figure 1-3 As shown, a deep hole comprehensive guarantee method for geological exploration, comprising the following steps:

[0032] Step 1. Fix the drilling rig on the ground above the geology to be tested, start the drilling rig to drive the drill pipe 2 to rotate, and the drill pipe 2 drives the drill bit 3 to drill a deep hole. After drilling to a certain depth, hammer the thick-walled casing 1 Penetrating deep holes for retaining walls;

[0033] Step 2: When a boulder is encountered during drilling, if the thick-walled casing 1 cannot pass through by hammering, start the water pump to input high-pressure water flow into the delivery chamber 7, and push the cutting tool body 22 out of the V-shaped cavity 4 , until the expanded width of the cutting body 22 on both sides of the drill bit 3 is greater than the outer diameter of the thick-walled casing 1, the drill bit 3 continues to rotate for reaming drilling, and an annular gap is drilled between the boulde...

Embodiment 2

[0043] Such as Figure 1-3 As shown, a deep hole comprehensive guarantee method for geological exploration comprises the following steps:

[0044] Step 1. Fix the drilling rig on the ground above the geology to be tested, start the drilling rig to drive the drill pipe 2 to rotate, and the drill pipe 2 drives the drill bit 3 to drill a deep hole. After drilling to a certain depth, hammer the thick-walled casing 1 Penetrating deep holes for retaining walls;

[0045] Step 2: When a boulder is encountered during drilling, if the thick-walled casing 1 cannot pass through by hammering, start the water pump to input high-pressure water flow into the delivery chamber 7, and push the cutting tool body 22 out of the V-shaped cavity 4 , until the expanded width of the cutting body 22 on both sides of the drill bit 3 is greater than the outer diameter of the thick-walled casing 1, the drill bit 3 continues to rotate for reaming drilling, and an annular gap is drilled between the boulder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com