Production and purification method and application of disulfide bond-containing polypeptide human brain natriuretic peptide hBNP

A technology of human brain natriuretic peptide and purification method is applied in the field of production and purification of disulfide bond-containing polypeptide human brain natriuretic peptide hBNP, which can solve the problem that there is no efficient expression of disulfide bond-containing polypeptide and human brain natriuretic peptide. The problems of high price of BNP products, cumbersome purification steps, etc., achieve the effect of being conducive to commercialization, simple purification, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

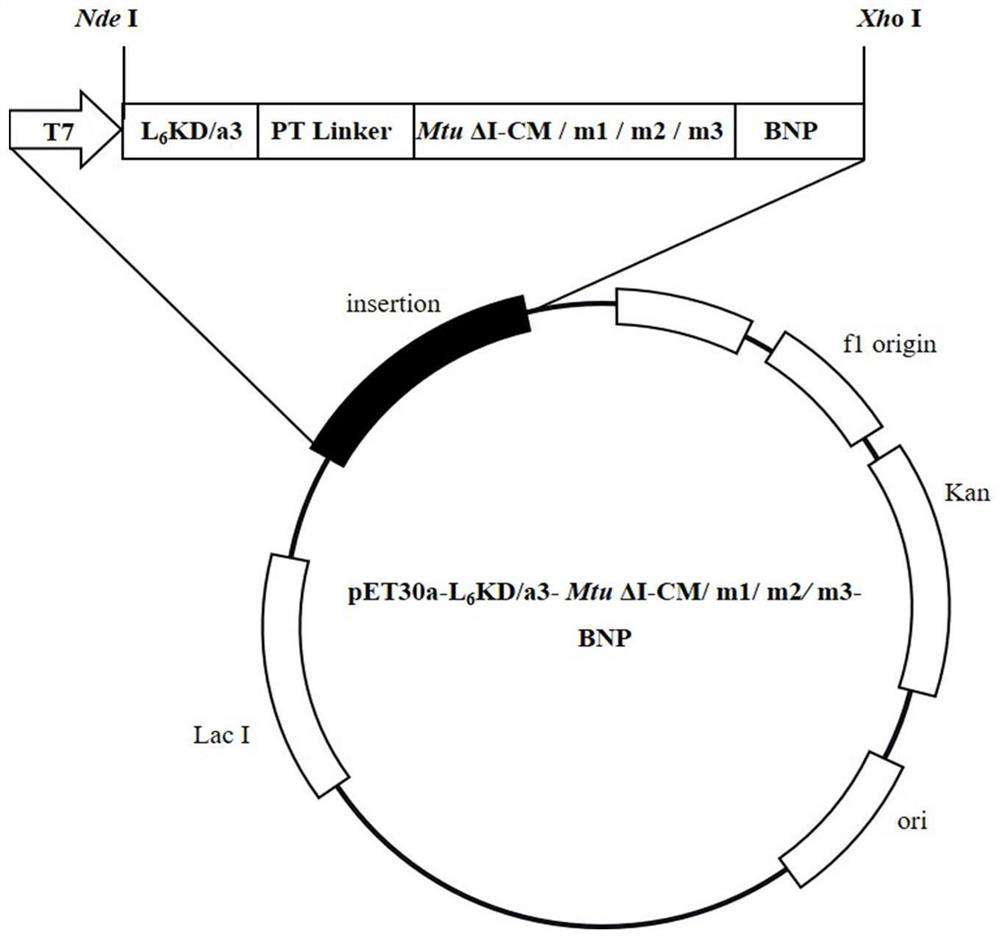

[0070] Example 1: Construction of human brain natriuretic peptide hBNP fusion protein expression vector containing intein MtuΔI-CM

[0071]The expression vectors used in the examples of this application pET30-L6KD-MtuΔI-CM-BNP, pET30-L6KD-MtuΔI-CM m1-BNP, pET30-L6KD-MtuΔI-CM m2-BNP, pET30-L6KD-MtuΔI-CM m3 The construction process of -BNP and pET30-α3-MtuΔI-CM-BNP is similar. The following takes the construction of pET30-L6KD-MtuΔI-CM-BNP as an example. The required primers are designed by oligo 6 and synthesized by Shanghai Sangong as shown in the table Oligonucleotide primers indicated in 1.

[0072] Table 1 Oligonucleotide primers used in this embodiment

[0073]

[0074]

[0075] Use Y200630-BNP-1F, Y200630-BNP-2R, Y200630-BNP-3F, Y200630-BNP-4R, Y200630-BNP-5F, Y200630-BNP-6R, Y200630-BNP-7F, Y200630-BNP-8R primers as The template was annealed and spliced by PCR reaction (PCR instrument (Bio-rad / C1000 Touch)) to obtain brain natriuretic peptide BNP polynucleotide...

Embodiment 2

[0080] Example 2: Expression and purification of human brain natriuretic peptide hBNP fusion protein in LB medium

[0081] The strain constructed in Example 1 (containing each plasmid as described above) was inoculated into LB liquid medium containing 50 μg / mL kanamycin, and cultivated in a shaker at 37° C. to logarithmic phase (OD 600 =0.4-0.6), add a final concentration of 0.2mMIPTG, induce at 18°C for 24 hours, harvest the cells, and measure the bacterial concentration OD 600 . 1 mL of OD 600 A cell mass of 1 is called 1OD.

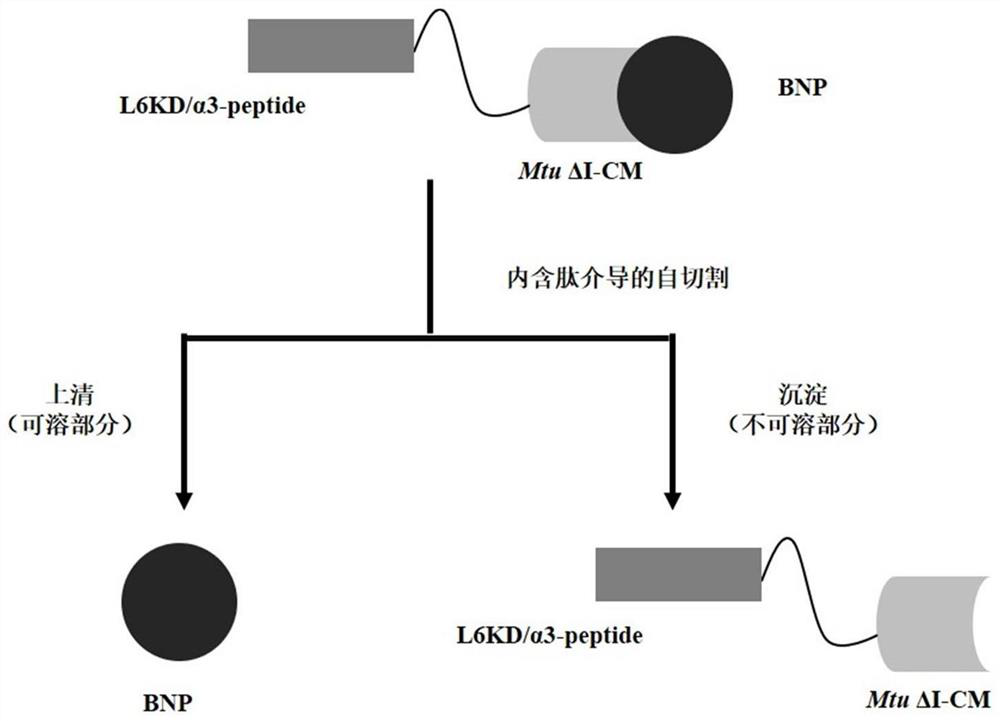

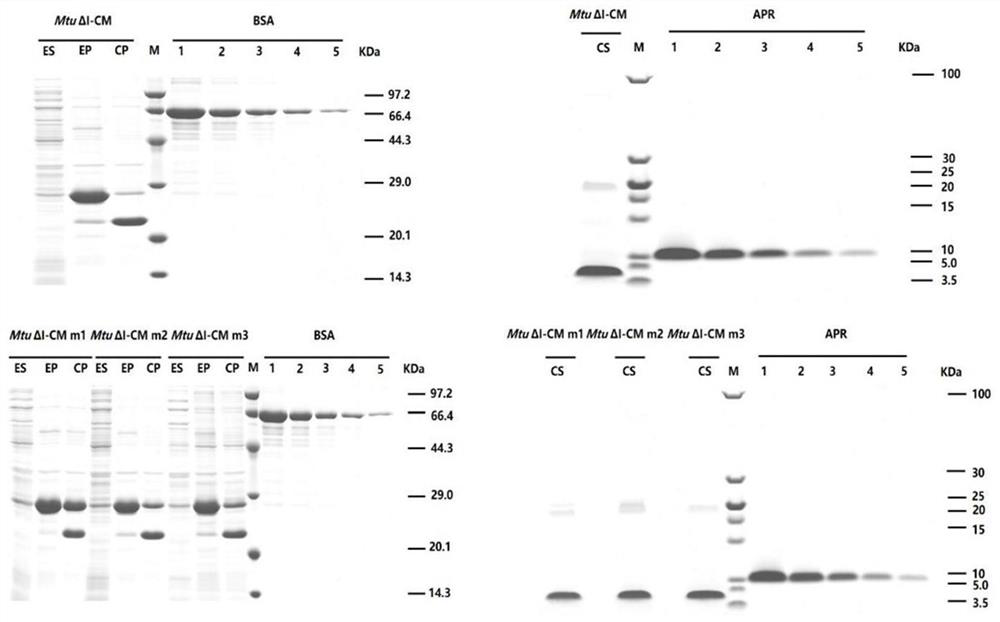

[0082] The thalline was treated with lysis buffer B1 (Tris of 2.4g, NaCl of 29.22g, NaCl of 0.37g 2 EDTA·2H 2 O was dissolved in 800 mL of water, adjusted to pH 8.5, added water to make up to 1 L), resuspended to 50 OD / mL, and subjected to ultrasonic crushing (crushing conditions: power 200 W, ultrasonic time 3 sec, interval time 3 sec, ultrasonic frequency 99 times). Centrifuge at 4°C and 15000g for 20min, and collect the supernatant and precip...

Embodiment 3

[0088] Example 3: Expression and purification of human brain natriuretic peptide hBNP fusion protein in fermentation medium

[0089] The strain constructed in Example 2 was inoculated into a fermentation medium containing 50 μg / mL kanamycin (Shao-YangHu et al., 2004), and cultivated in a shaker at 37° C. to logarithmic phase (OD 600 =0.6-0.8), adding a final concentration of 0.2mM IPTG, inducing at 18°C for 24 hours, harvesting the cells, and measuring the bacterial concentration OD 600 1 mL of OD 600 A cell mass of 1 is called 1OD. The components of the fermentation medium used are shown in Table 3.

[0090] Table 3 Fermentation Medium Components

[0091]

[0092] Glucose was sterilized separately from other components, sterilized at 121°C for 20 minutes, and the trace element solution was filtered and sterilized on an ultra-clean bench with a 0.22 μm filter head. After the medium was prepared, kanamycin with a final concentration of 50 mg / L was added before use.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com