Flame-retardant silica gel pressure-sensitive adhesive, preparation method and adhesive tape

A flame-retardant silica gel and pressure-sensitive adhesive technology, which is applied in the direction of pressure-sensitive films/sheets, adhesives, film/sheet-shaped adhesives, etc., can solve problems such as low safety, environmental pollution by-products, and few varieties, and achieve High peel force, halogen free, modulus improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

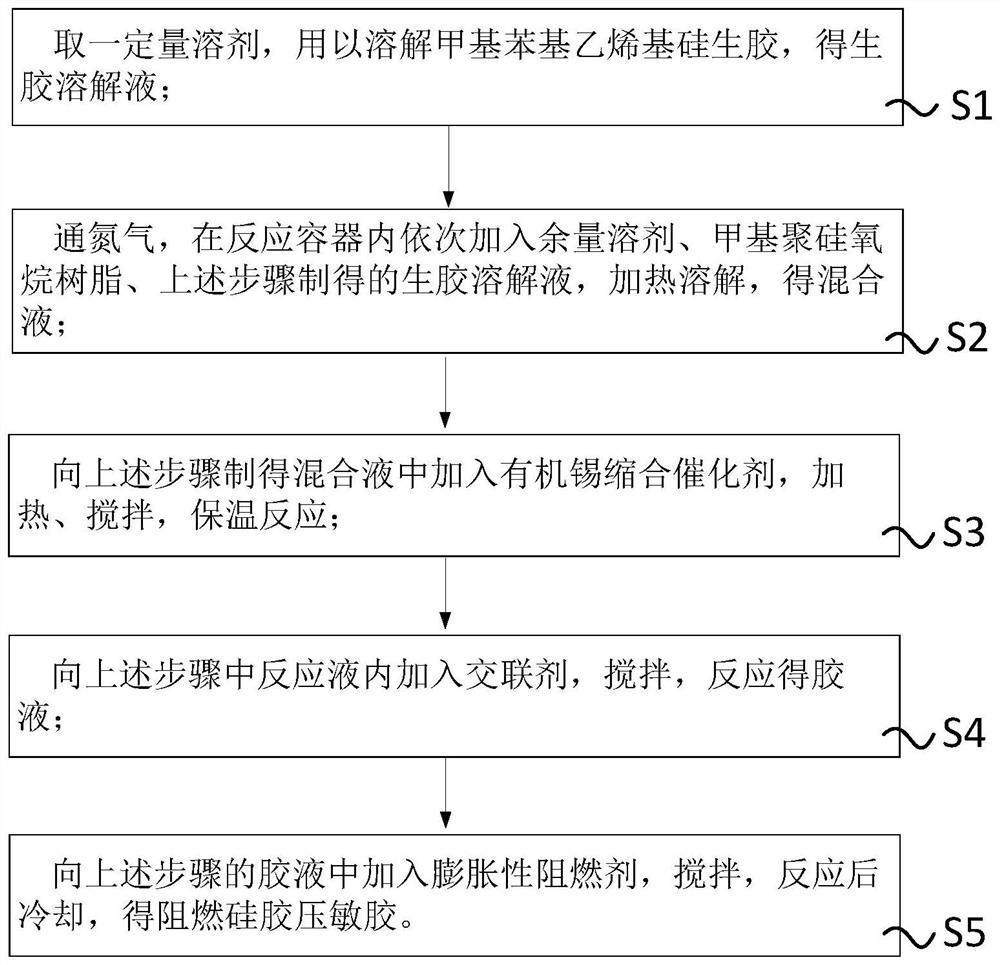

[0039] The present invention also provides a method for preparing a flame-retardant silicone pressure-sensitive adhesive as described above, such as figure 2 shown, including the following steps:

[0040] S1. Take a certain amount of solvent to dissolve methylphenylvinyl silicon raw rubber to obtain a raw rubber solution;

[0041] S2, blowing nitrogen, sequentially adding the remaining solvent, methyl polysiloxane resin, and the raw rubber dissolving solution prepared in step S1 into the reaction vessel, heating and dissolving to obtain a mixed solution;

[0042] S3, adding an organotin condensation catalyst to the mixed solution prepared in step S2, heating, stirring, and heat preservation reaction;

[0043] S4, adding a crosslinking agent to the reaction solution in step S3, stirring, and reacting to obtain a glue;

[0044] S5. Add an intumescent flame retardant to the glue in step S4, stir, and cool after reaction to obtain a flame-retardant silicone pressure-sensitive a...

Embodiment 1

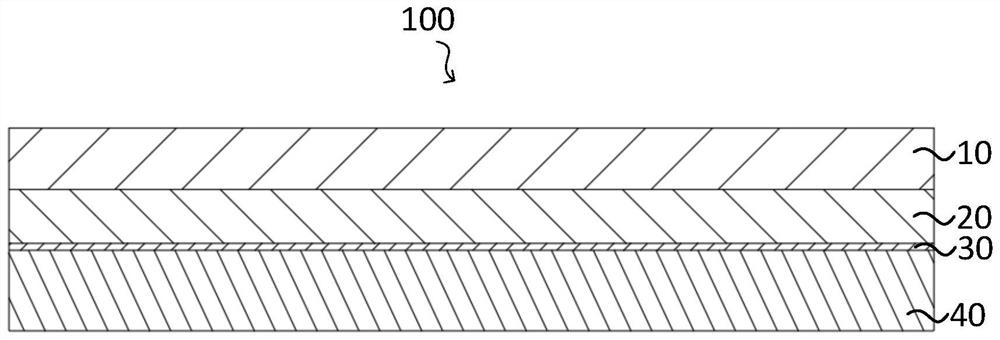

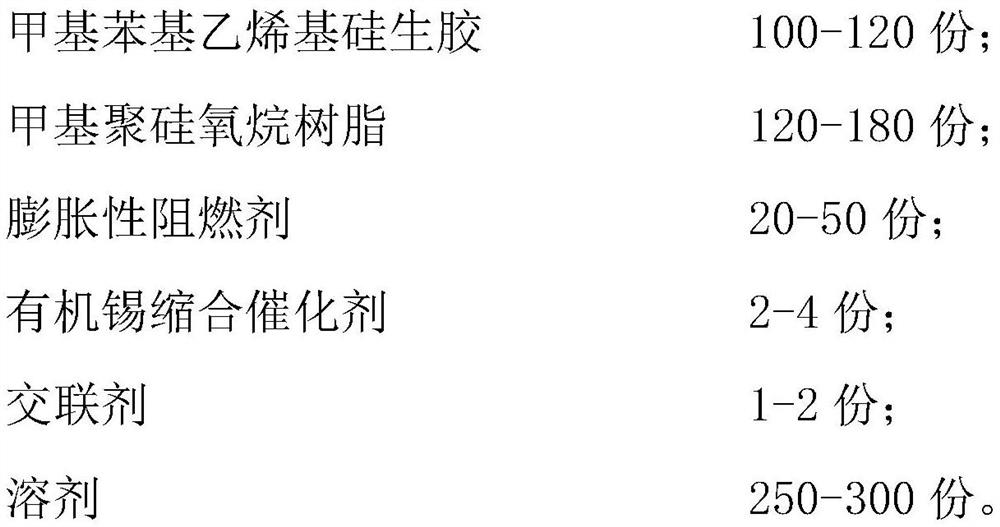

[0058] The invention provides an adhesive tape, which sequentially includes a release film layer 10, a flame-retardant silicone pressure-sensitive adhesive layer 20, a primer layer 30, and a flame-retardant substrate 40; wherein, the release film layer 10 is a transparent fluorine release film layer , with a thickness of 50 μm; the flame-retardant silicone pressure-sensitive adhesive layer 20 is 20 μm thick; the primer layer 30 is a silicone layer with a thickness of 0.9 μm; 20 is coated and cured with flame-retardant silicone pressure-sensitive adhesive; the flame-retardant silicone pressure-sensitive adhesive includes the following raw materials in parts by weight:

[0059]

[0060] Among them, the molecular weight of methyl phenyl vinyl silicone raw rubber is 600,000, the phenyl content in methyl phenyl vinyl silicone raw rubber is 8%, and the vinyl content is 4%; both ends of the methyl polysiloxane resin molecular chain All have a methyl group, and its molecular weight...

Embodiment 2

[0068] The present invention provides an adhesive tape, which is different from Example 1 in that the flame-retardant silicone pressure-sensitive adhesive layer 20 is coated with flame-retardant silicone pressure-sensitive adhesive and includes the following raw materials in parts by weight:

[0069]

[0070] When preparing the flame-retardant silicone pressure-sensitive adhesive, 210 parts of xylene was used to dissolve the methylphenylvinyl silicone raw rubber. All the other preparation processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com