Slow-release microbial organic fertilizer and preparation method thereof

An organic fertilizer and microorganism technology, which is applied in the field of slow-release microbial organic fertilizer and its preparation, can solve the problems that crop growth cannot be promoted for a long time, the action period of nutrients is long, the fertilizer efficiency is reduced, etc., and the activity maintenance time can be prolonged. , the effect of increasing oxygen content and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

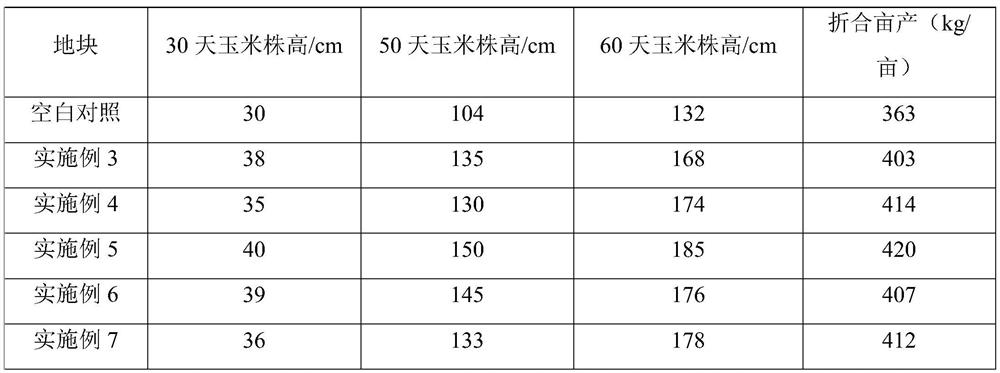

Examples

Embodiment 1

[0029] Preparation of modified medical stone

[0030] (1) Medical stone pre-treatment: put 200-300 mesh medical stone powder in hydrochloric acid solution, 300-400W ultrasonic treatment for 30-60min, wash until the washing liquid is neutral and dry, and then obtain activated medical stone;

[0031] (2) Get 10kg of activated medical stone powder and disperse it in an aqueous solution, add ammonia water dropwise to adjust the pH of the system to be 8-9, and add 4kg of gamma-glycidyl etheroxypropyltrimethoxysilane to it under stirring conditions Ethanol solution (the weight ratio of γ-glycidyl etheroxypropyltrimethoxysilane to ethanol is 1:1), stirred and reacted at 50°C for 3 hours, filtered, washed and dried; the modified medical stone can be obtained;

Embodiment 2

[0033] Preparation of microbial fermentation broth

[0034] Inoculate methylotrophic Bacillus, Bacillus subtilis, and Bacillus lateralis into LB liquid medium, culture at 28-32°C for 24-48 hours to obtain activated seed liquid; take 2kg of methylotrophic Bacillus seeds Liquid, 1kg Bacillus subtilis seed liquid, 1kg Bacillus lateral sporosum seed liquid are mixed and then transferred to the fermenter, after carrying out fermentation and cultivation for 24-48h, the composite microbial fermentation liquid 1 is obtained; the inoculation amount of the seed liquid is 5% of the total volume of the tank; the number of effective viable bacteria in the fermentation broth is not less than 5×10 9 cfu / g;

[0035] Inoculate methylotrophic Bacillus, Bacillus subtilis, and Bacillus lateralis into LB liquid medium respectively, and culture them at 28-32°C for 24-48 hours to obtain activated seed liquid; take 3kg of methylotrophic Bacillus seeds Liquid, 1kg Bacillus subtilis seed liquid, 1kg ...

Embodiment 3

[0038] A slow-release microbial organic fertilizer, the slow-release microbial organic fertilizer includes a core layer and a coating layer; the core layer is composed of fermented fertilizer and urea-formaldehyde; the fermented fertilizer is betel nut Slag powder, mulberry leaf powder, animal excrement, fish scale powder and modified medical stone powder are obtained through the fermentation of compound microorganisms; the coating layer is composed of konjac powder, sodium alginate and boric acid; the compound microorganism is composed of methyl nutrition Bacillus type, Bacillus subtilis, Bacillus lateral spores.

[0039] Its preparation method specifically comprises the following steps:

[0040] (1) Preparation of fermented fertilizer

[0041] 1.1) Take 15kg of betel nut residue powder and 8kg of mulberry leaf powder and 24kg of animal feces, mix and stir evenly, and then place it under sunlight for 24-48 hours to obtain a mixed organic material;

[0042] 1.2) Add 2.2kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com